Mechanical timing drive assembly

A technology for transmission components and machinery, applied in mechanical equipment, transmission devices, packaging, etc., can solve the problems of low reliability and high energy consumption, and achieve the effects of strong reliability, low energy consumption and high structural stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

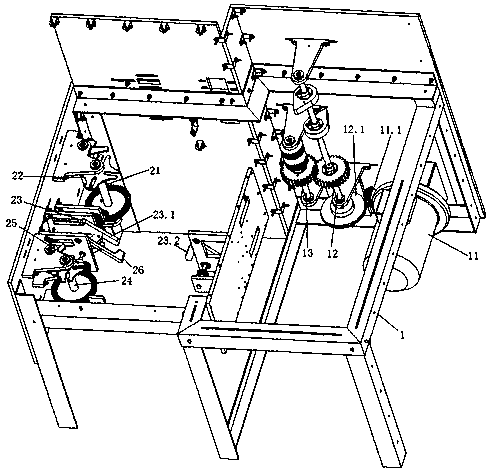

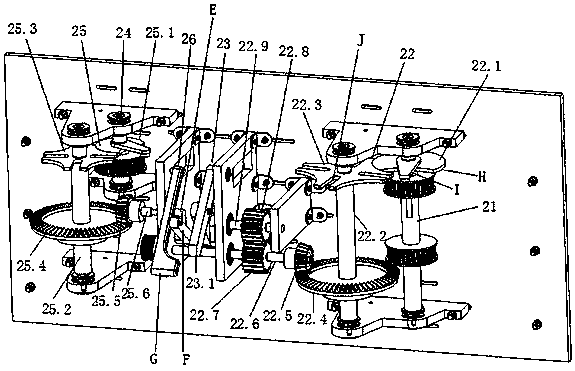

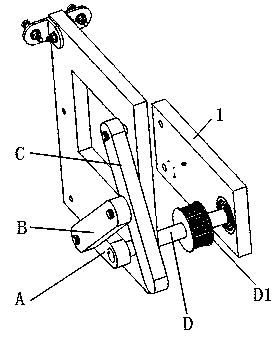

[0023] Combine below Figure 1 to Figure 3 The embodiments of the present invention will be described in detail.

[0024] The mechanical timing transmission assembly includes a frame 1 equipped with a motor 11 and a timing transmission mechanism 2 mounted in the frame 1 and connected to the motor 11 in transmission, characterized in that the timing transmission mechanism 2 includes a transmission connection with the motor 11 And the front dial shaft 21 is rotatably mounted on the bracket 1, the front dial assembly 22 is drivingly connected to the front dial shaft 21, the front crank swing assembly 23 is drivingly connected to the front dial assembly 22, and the front dial The shaft 21 is connected to the rear dial shaft 24, the rear dial assembly 25 drivingly connected to the rear dial shaft 24, and the rear crank swing assembly 26 drivingly connected to the rear dial assembly 25 through a timing belt. The front dial shaft 21 rotates to drive the front The dial assembly 22 rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com