An Anti-Magnetic Levitation Gas Flowmeter with Embedded Photoelectric Detection Unit

A gas flowmeter and photoelectric detection technology, applied in the direction of measuring flow/mass flow, measuring device, liquid/fluid solid measurement, etc., can solve the problem of insufficient detection accuracy, insufficient resolution of gas flowmeter, complex sensor processing circuit, etc. problem, to achieve the effect of reducing friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

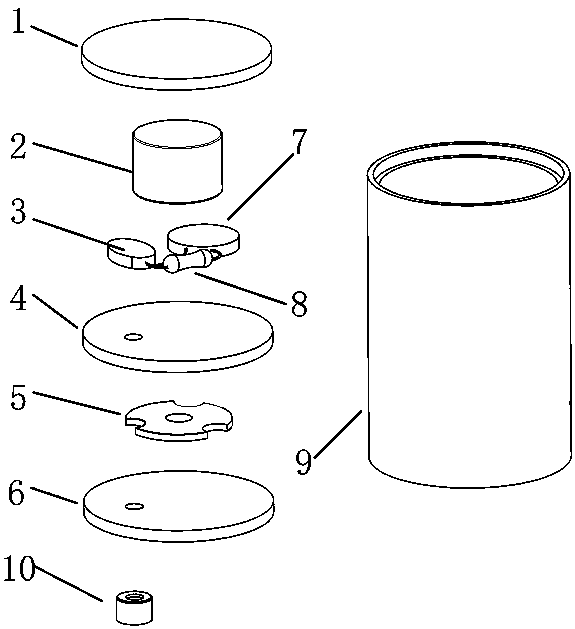

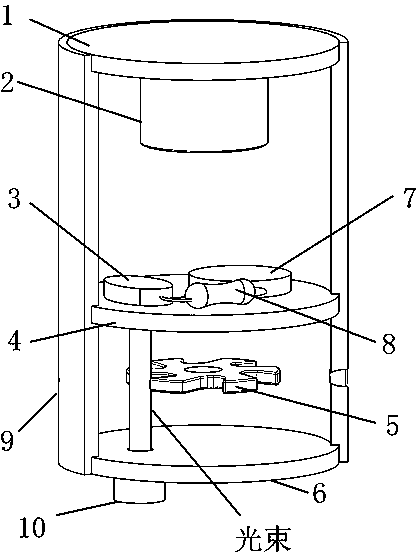

[0023] Such as figure 1As shown, an anti-magnetic levitation gas flowmeter with embedded photoelectric detection unit is an air flow meter based on the anti-magnetic levitation mechanism, including a housing 9 and a cover plate 1, the cover plate 1 is arranged on the upper part of the housing 9, and an anti-magnetic levitation system and a photoelectric contrast sensor unit, the anti-magnetic levitation system includes a lifting permanent magnet 2, an upper pyrolytic graphite plate 4, a magnet rotor 5 and a lower pyrolytic graphite plate 6 from top to bottom, and the lifting permanent magnet 2 Located under the cover plate 1, the lifting permanent magnet 2 is a cylinder with a diameter of 15mm and a thickness of 10mm, and is a N35 NdFeB magnet. The upper pyrolytic graphite plate 4 and the lower pyrolytic graphite plate 6 are cylindrical structures with a diameter of 22 mm and a thickness of 2 mm, and the upper pyrolytic graphite plate 4 and the lower pyrolytic graphite plate 6...

Embodiment 2

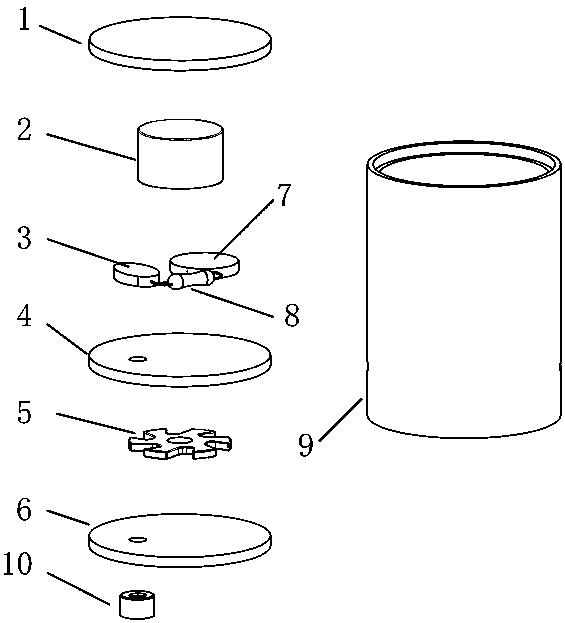

[0027] Such as figure 2 As shown, an anti-magnetic levitation gas flowmeter with embedded photoelectric detection unit is an air flow meter based on the anti-magnetic levitation mechanism, including a housing 9 and a cover plate 1, the cover plate 1 is arranged on the upper part of the housing 9, and an anti-magnetic levitation system and a photoelectric contrast sensor unit, the anti-magnetic levitation system includes a lifting permanent magnet 2, an upper pyrolytic graphite plate 4, a magnet rotor 5 and a lower pyrolytic graphite plate 6 from top to bottom, and the lifting permanent magnet 2 It is located under the cover plate 1. The lifting permanent magnet 2 is in the form of a circular ring with an outer diameter of 15 mm, an inner diameter of 5 mm, a thickness of 10 mm, and a grade of N35. The upper pyrolytic graphite plate 4 and the lower pyrolytic graphite plate 6 have a diameter of 22 mm and a thickness of 2 mm. The upper pyrolytic graphite plate 4 and the lower py...

Embodiment 3

[0031] Such as Figure 2-5 As shown, an anti-magnetic levitation gas flowmeter with embedded photoelectric detection unit is an air flow meter based on the anti-magnetic levitation mechanism, including a housing 9 and a cover plate 1, the cover plate 1 is arranged on the upper part of the housing 9, and an anti-magnetic levitation system and the photoelectric contrast sensor unit, the anti-magnetic levitation system includes a lifting permanent magnet 2, an upper pyrolytic graphite plate 4, a magnet rotor 5 and a lower pyrolytic graphite plate 6 from top to bottom, and the lifting permanent magnet 2 is located at Below the cover plate 1. Lifting permanent magnet 2 is an annular ring with an outer diameter of 15mm, an inner diameter of 5mm, and a thickness of 10mm, and the grade is N35. Both the upper pyrolytic graphite plate 4 and the lower pyrolytic graphite plate 6 are cylinders with a diameter of 22 mm and a thickness of 2 mm. Through holes with a diameter of 3 mm are pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com