Comprehensive testing device for automobile gear-box

A technology for comprehensive testing of automobile gearboxes, applied in the field of gearbox testing devices, can solve the problems of inability to obtain parameter relationship curves, low measurement accuracy, and inability to effectively prevent errors, and achieve optimized control procedures, accurate measurement, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

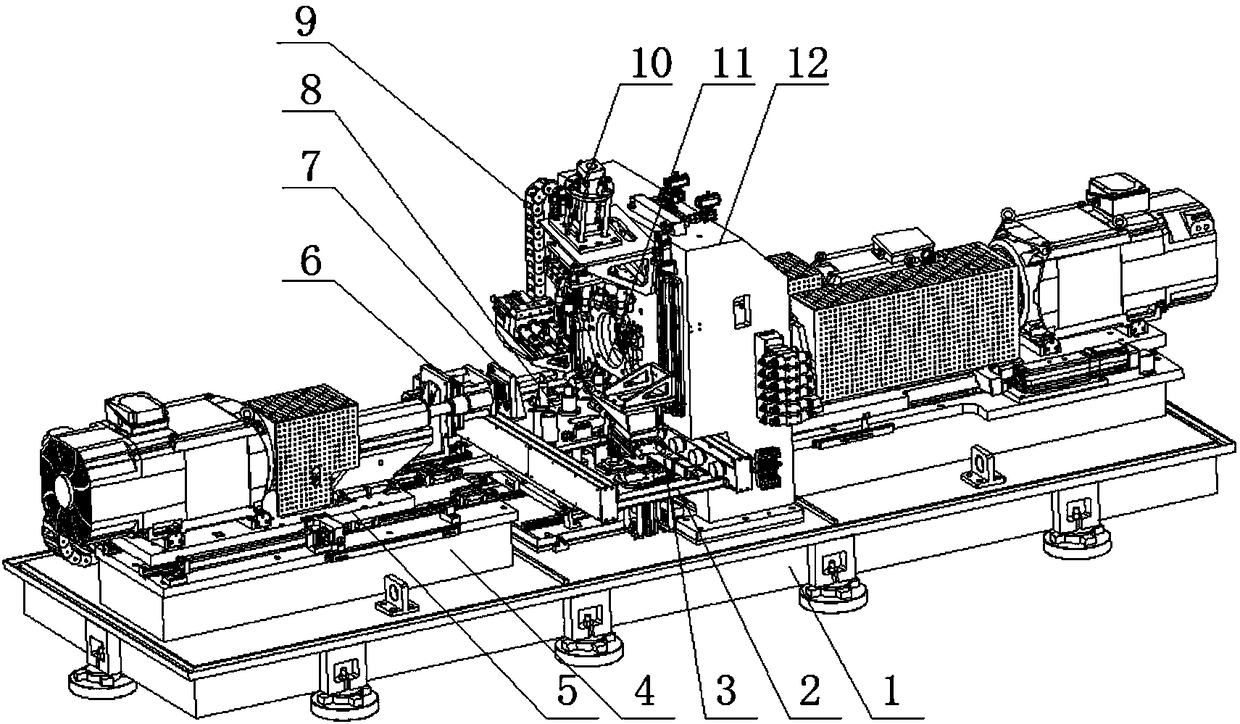

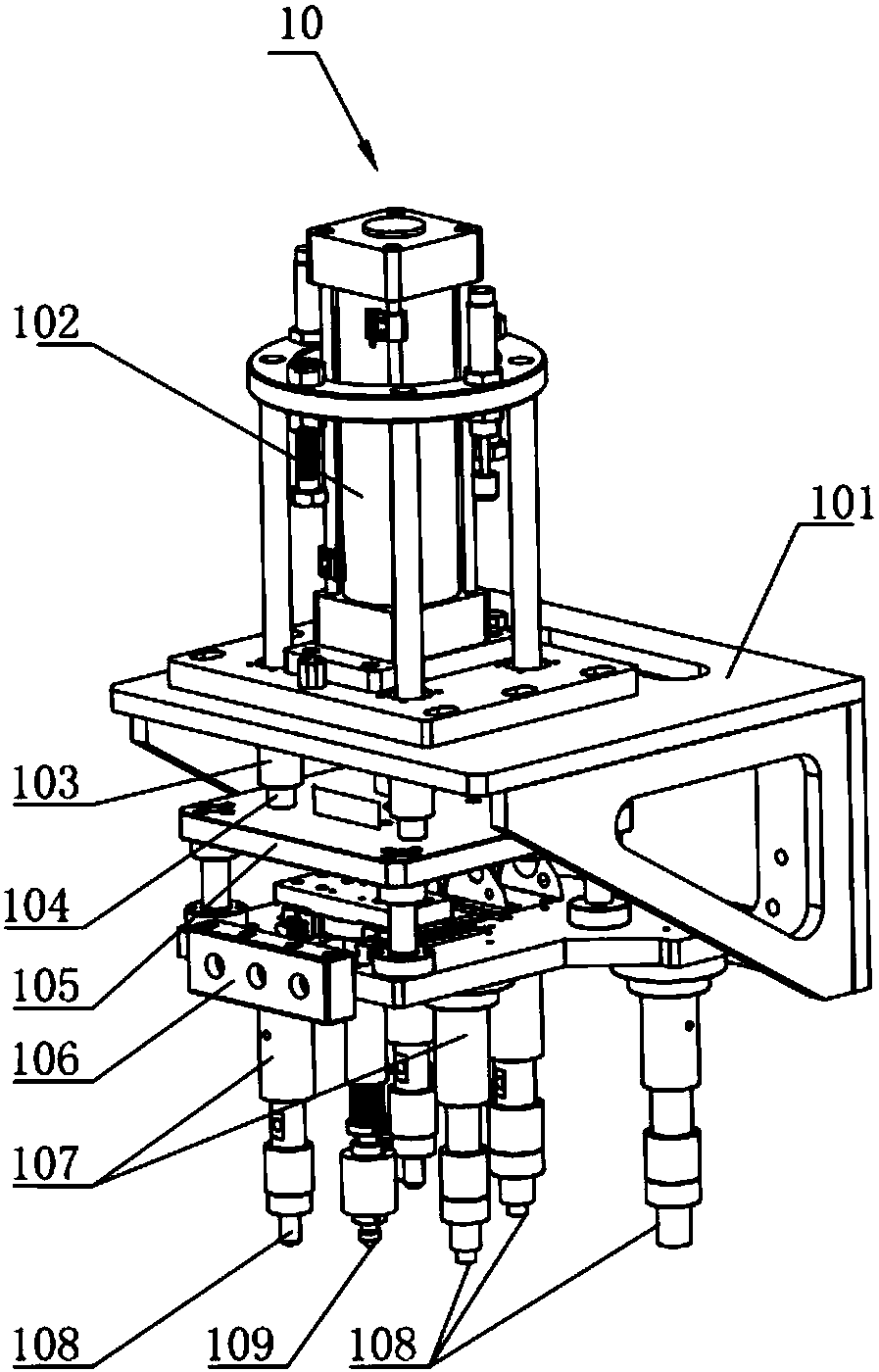

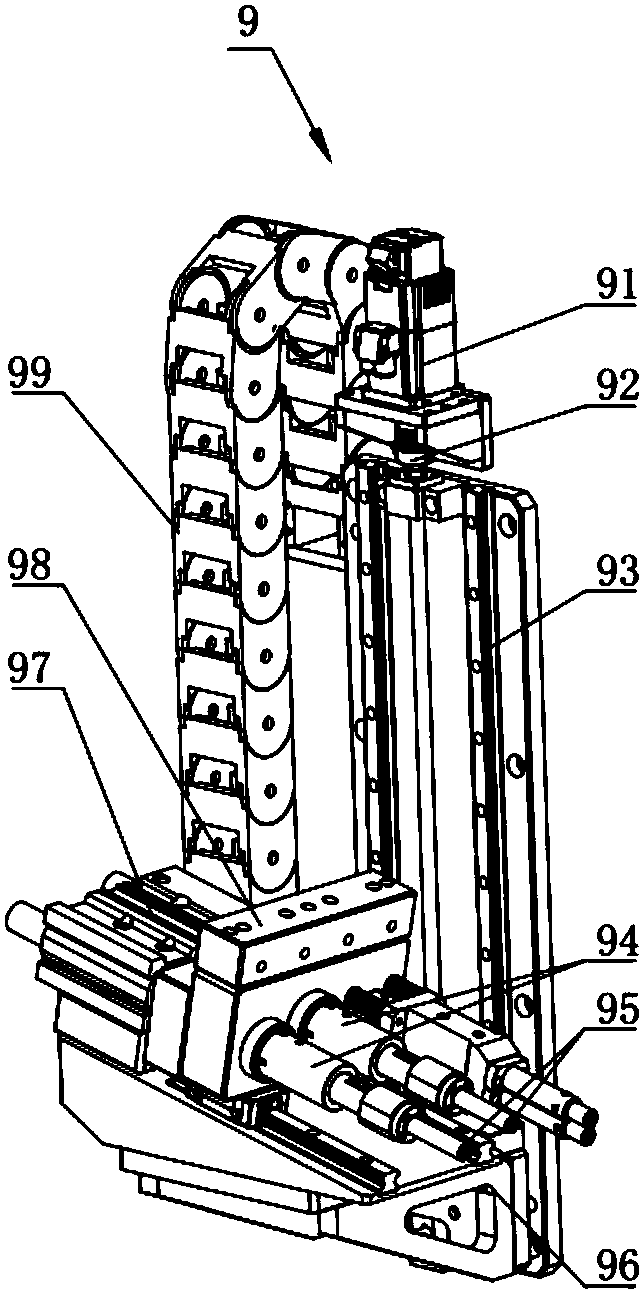

[0029] Such as figure 1 As shown, the automotive gearbox comprehensive test device of the present embodiment includes a fixedly installed base 1, a jacking mechanism 2 that translates and lifts along it is installed on the base 1, and a vertical column 12 perpendicular to the base 1. The shift detection mechanism 3 and the tooling plate 8 are fixedly installed on the surface of the lifting mechanism 2, the first docking mechanism 10 is installed on the upper end surface of the column 12, the type change plate 11 is fixedly installed in the middle, and the left and right sides of the end surface of the column 12 are respectively installed. There is a left docking mechanism 9 and a right docking mechanism, a docking plate 7 and an elastic mechanism perpendicular to it are installed on the tooling plate 8, and the first docking copper needle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com