Emergency processing method for network failure of withdrawal and straightening unit and system thereof

An emergency treatment and tension leveling machine technology, applied in general control systems, control/regulation systems, comprehensive factory control, etc., can solve problems such as slowing down the pulling speed, inability to continuously control the tension leveling machine, and a large number of waste blanks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

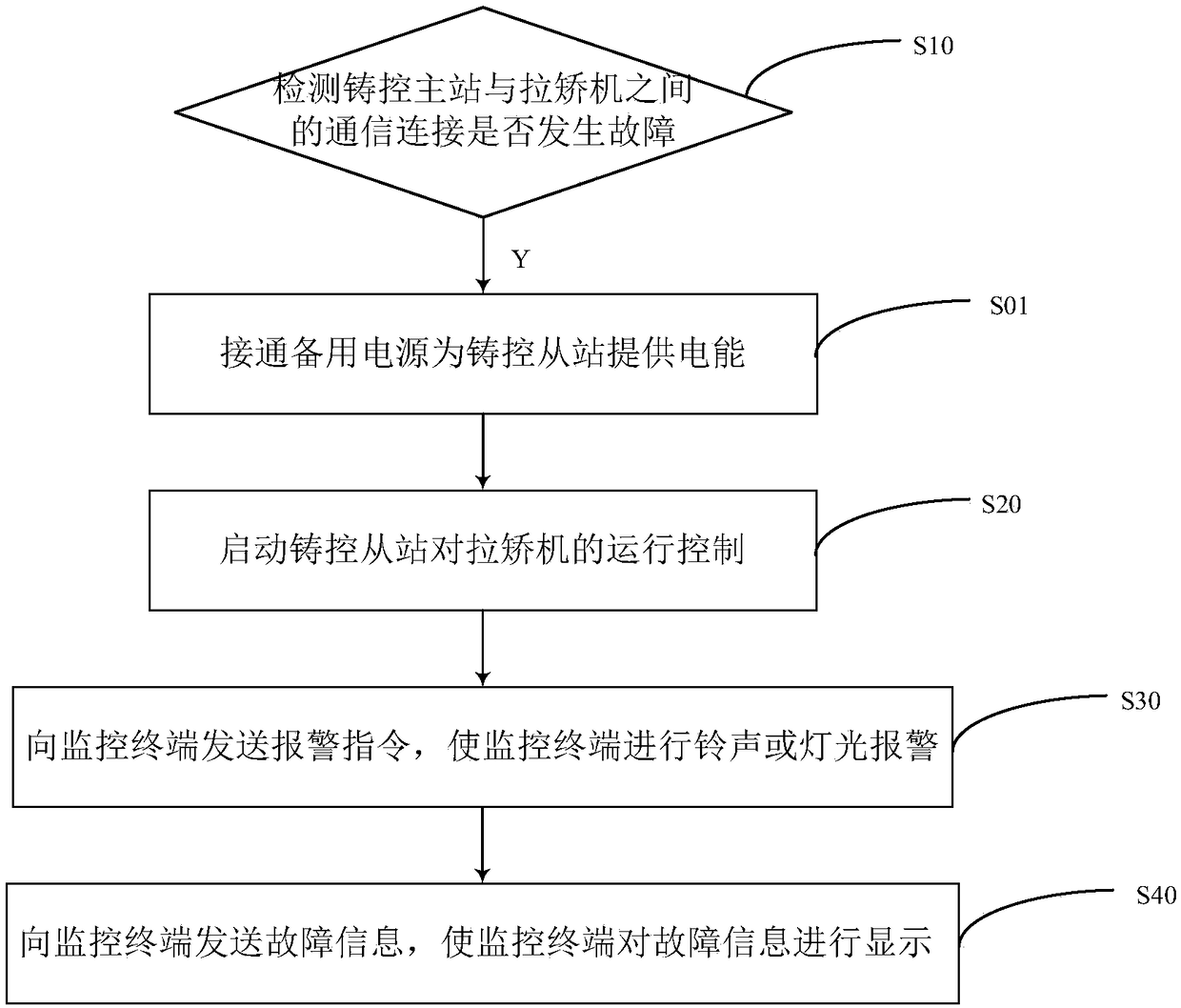

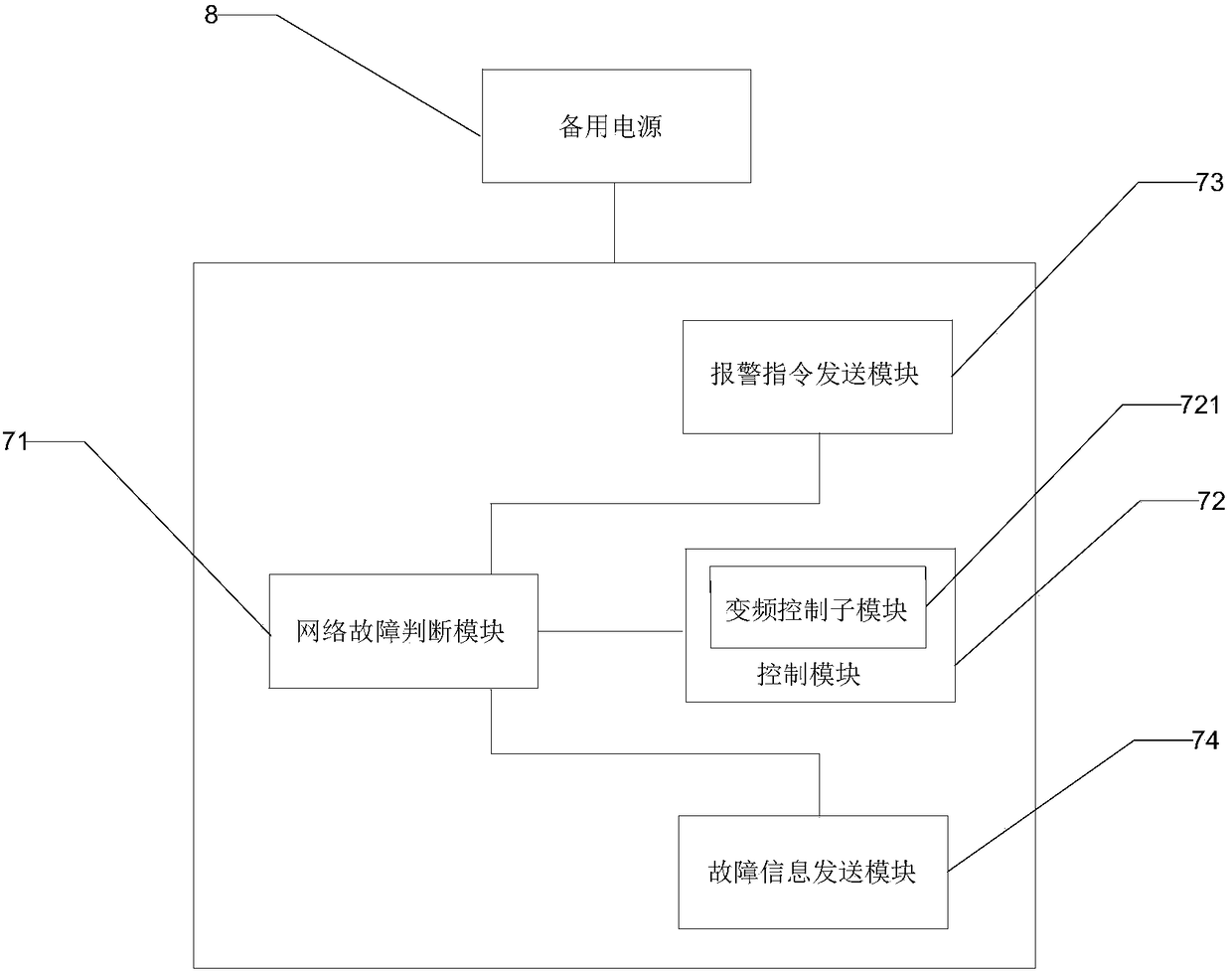

[0026] figure 1 For this application, a flow chart of an emergency treatment method for a tension leveler after the network is disconnected, such as figure 1 As shown, the emergency treatment method includes, step S10, detecting in real time whether the communication connection between the casting control master station and the tension leveler is faulty through the casting control slave station. Step S20, when it is detected that the communication connection between the casting control master station and the tension leveler fails, start the casting control slave station to control the operation of the tension leveler.

[0027] In the previous continuous casting process, if the communication network fails, the casting control master station will not be able to continue to send control commands to the tension leveler, so that the tension leveler cannot perform normal tension leveling work, resulting in a large amount of waste billets , or lead to problems such as casting device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com