Dynamic regulation method for power of high-voltage electrode boiler

A technology of dynamic adjustment and high-voltage electrodes, which is applied in the direction of temperature control using electric methods, auxiliary controllers with auxiliary heating devices, etc., can solve the problem of overall efficiency decline, unable to meet the peak-shaving quality requirements of power dispatching departments, and solid heat storage The material is not environmentally friendly and other issues, to achieve the effect of fast power adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

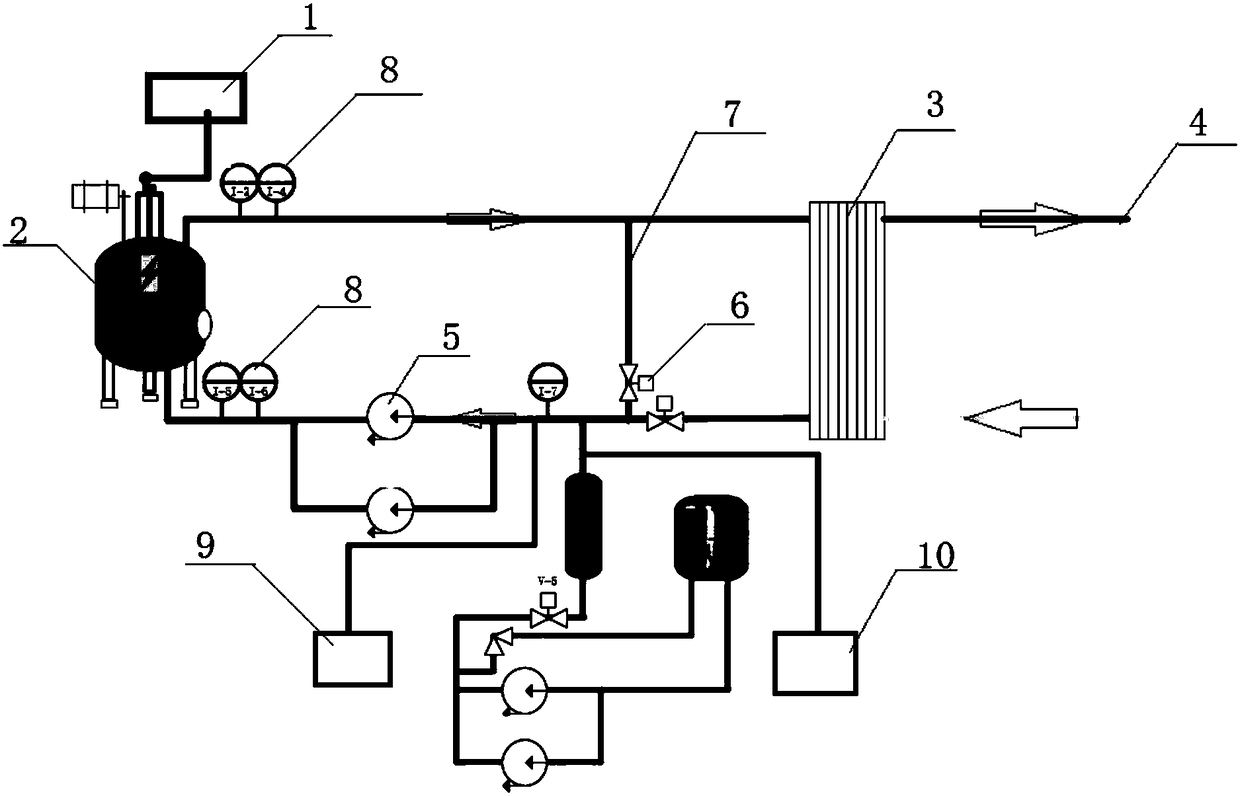

[0021] Embodiment 1: as figure 1 As shown, a high-voltage electrode direct-heating boiler system for power grid peak-shaving heating supply includes a high-voltage power supply device 1, a high-voltage electrode direct-heating boiler body 2, a plate heat exchanger 3, a heat network system 4, and a controller. The high-voltage power supply device 1 is connected to the high-voltage electrode direct-heating boiler body 2, through which the electric energy is converted into heat energy; the high-voltage electrode direct-heating boiler body 2 is connected to the high-voltage electrode direct-heating boiler body 2 through the heat exchanger 3 The heat network system 4 is connected to exchange energy; with the heat exchanger 3 as the dividing line, the side of the high-voltage electrode direct heating boiler body 2 is the primary side system, and the side of the heat network system 4 is the secondary side system; the primary side system is a closed cycle, and the water circulation is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com