Finite element thermal analysis equivalent method for contact resistance of ground wire and pre-twisted wire contact port

A technology of contact resistance and pre-twisted wire, which is applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as disconnection of overhead ground wires, affecting the safe and stable operation of the power grid, and power outages in the power grid, so as to reduce the required the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

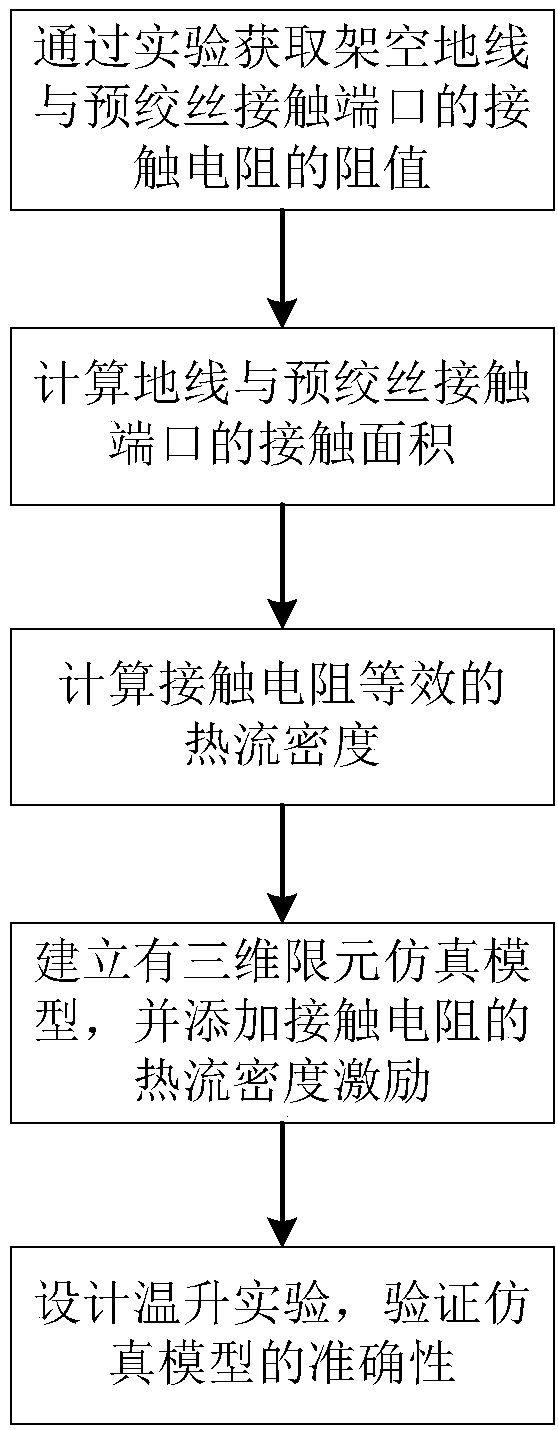

[0034] A kind of contact resistance finite element thermal analysis equivalent method of ground wire and pre-twisted wire contact port, the step flow chart is as follows figure 1 As shown, it mainly includes the following steps:

[0035] Step 1, obtain the resistance value of the contact resistance of the contact port of the overhead ground wire and the pre-twisted wire through experiments;

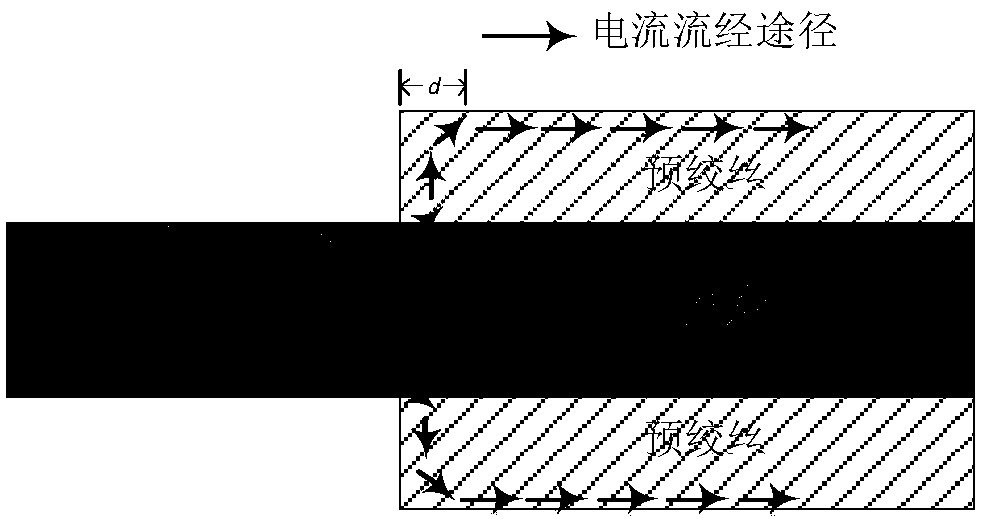

[0036] Step 2, at the contact port between the ground wire and the pre-twisted wire, the thermal effect generated by the contact resistance is caused by the diffusion of current here, and the contact area corresponding to the contact resistance is obtained by using finite element electromagnetic simulation or analytical calculation;

[0037] Step 3, calculate the heat flux according to the contact resistance obtained by the experiment and the contact area obtained by calculation;

[0038] Step 4, use the finite element simulation software ANSYS or comsol to establish a three-dimensional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com