Ground photovoltaic power station for using bamboo-wound composite pressure pipe columns to manufacture photovoltaic support

A technology of ground photovoltaic power stations and composite pressure tubes, applied in photovoltaic power generation, support structures of photovoltaic modules, photovoltaic modules, etc., to achieve the effects of protecting the ecological environment, increasing uses, and increasing jobs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

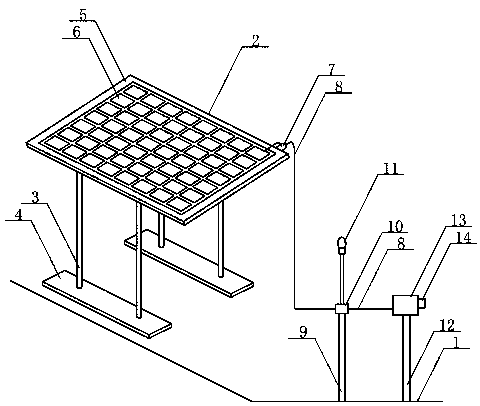

[0020] The front and rear two bamboo winding composite pressure bottom plates are set on the ground, and a bamboo winding composite pressure pipe column armor with a shorter height is respectively installed on the left half and the right half of the front bamboo winding composite pressure bottom plate, Install a taller bamboo winding composite pressure pipe column armor on the left half and right half of a bamboo winding composite pressure floor at the back, and install on the top surface of the four bamboo winding composite pressure pipe column armors For monocrystalline silicon solar cells, install a bamboo winding composite material frame around the monocrystalline silicon solar cell, install a micro inverter on the bamboo winding composite material frame, and install it on the ground on the right side of the bamboo winding composite pressure tube column A Bamboo winding composite pressure pipe column B, install a transformer on the top surface of bamboo winding composite pr...

Embodiment 2

[0022]The front and rear two bamboo winding composite pressure bottom plates are set on the ground, and a shorter bamboo winding composite pressure pipe column armor is respectively installed on the left half and the right half of the front bamboo winding composite pressure bottom plate, Install a taller bamboo winding composite pressure pipe column armor on the left half and the right half of a bamboo winding composite pressure floor at the back, and install on the top surface of the four bamboo winding composite pressure pipe column armors For polycrystalline silicon solar cells, a bamboo winding composite material frame is installed around the polycrystalline silicon solar cell, a micro inverter is installed on the bamboo winding composite material frame, and a bamboo winding composite pressure is installed on the ground on the right side of the bamboo winding composite pressure tube column A Pipe column B, install a transformer on the top surface of bamboo winding composite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com