Embedded-copper-block printed circuit board and manufacture method thereof

A technology for printed circuit boards and manufacturing methods, which is applied in the fields of printed circuits, printed circuits, multilayer circuit manufacturing, etc., can solve the problems of limited improvement of the overall heat dissipation performance of the circuit board, poor heat dissipation effect of the circuit board, etc., and achieve easy solution Cracking, good heat dissipation effect, and firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

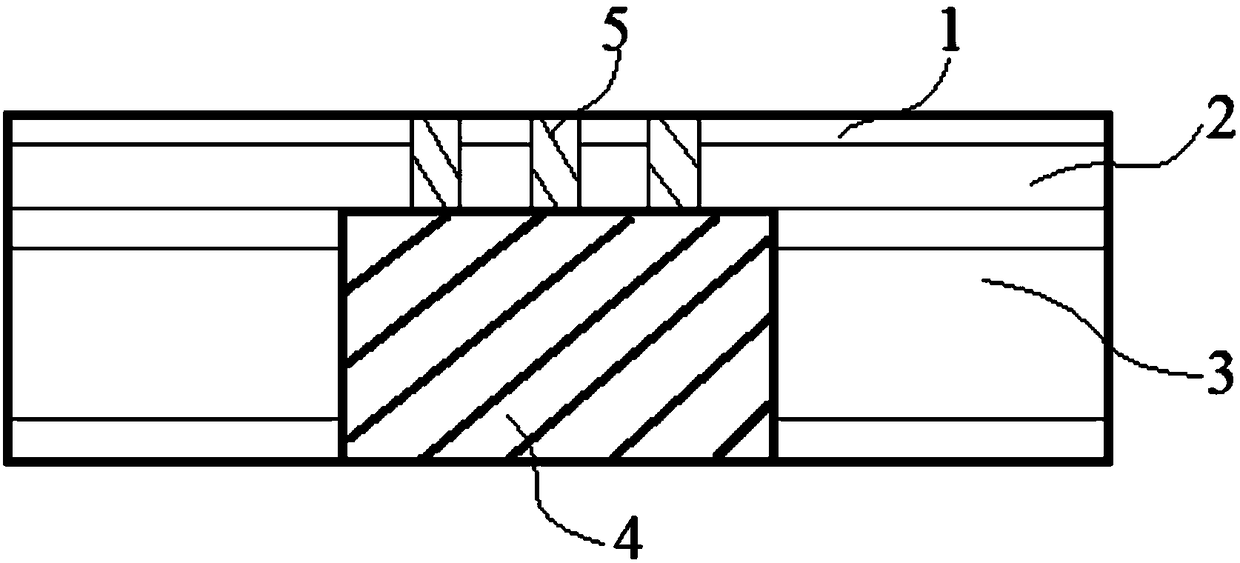

[0032] This embodiment provides a buried copper block printed circuit board, which is as follows figure 1 As shown, the top circuit layer 1, the prepreg layer 2 and the bottom circuit layer 3 are arranged sequentially from top to bottom, wherein the top circuit layer 1 is a copper foil layer with a circuit pattern, and its thickness is HOZ, and the bottom circuit layer Layer 3 is formed by cross-lamination of multi-layer PCB core boards with circuit patterns and prepregs (a prepreg is arranged between every two core boards). In this embodiment, the bottom circuit layer 3 is 4 layers, that is, It contains four layers of core boards and three layers of prepreg, and the thickness of the bottom circuit layer 3 is 0.2mm. And the material of the prepreg in the bottom circuit layer 3 is the same as that of the prepreg layer 2, the resin content is 68%, and the thickness of the prepreg layer 2 is 0.076mm.

[0033] The bottom circuit layer 3 is provided with an accommodation groove, t...

Embodiment 2

[0035] This embodiment provides a buried copper block printed circuit board, which is as follows figure 1 As shown, the top circuit layer 1, the prepreg layer 2 and the bottom circuit layer 3 are arranged sequentially from top to bottom, wherein the top circuit layer 1 is a copper foil layer with a circuit pattern, and its thickness is 1OZ, and the bottom circuit layer Layer 3 is formed by cross-lamination of multilayer PCB core boards and prepregs with circuit patterns (a prepreg is arranged between every two core boards). In this embodiment, the bottom circuit layer 3 is 20 layers, that is, It contains 20 layers of core boards and 19 layers of prepregs, and the thickness of the bottom circuit layer 3 is 6mm. And the material of the prepreg in the bottom circuit layer 3 is the same as that of the prepreg layer 2, the resin content is 75%, and the thickness of the prepreg layer 2 is 0.13 mm.

[0036] The bottom circuit layer 3 is provided with an accommodation groove, the acc...

Embodiment 3

[0038] This embodiment provides a buried copper block printed circuit board, which is as follows figure 1 As shown, the top circuit layer 1, the prepreg layer 2 and the bottom circuit layer 3 are arranged sequentially from top to bottom, wherein the top circuit layer 1 is a copper foil layer with a circuit pattern, and its thickness is 1OZ, and the bottom circuit layer Layer 3 is formed by cross-lamination of multi-layer PCB core boards and prepregs with circuit patterns (a prepreg is arranged between every two core boards). In this embodiment, the bottom circuit layer 3 is 10 layers, that is, It contains 10 layers of core boards and 9 layers of prepregs, and the thickness of the bottom circuit layer 3 is 3mm. Moreover, the material of the prepreg in the bottom circuit layer 3 is the same as that of the prepreg layer 2, the resin content is 70%, and the thickness of the prepreg layer 2 is 0.1 mm.

[0039]The bottom circuit layer 3 is provided with an accommodation groove, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com