Tool for preventing flywheel of rear power take-off engine from rotation

A technology of engine and flywheel, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of damage to the flywheel shell E flywheel ring gear, etc., and achieve the goal of not easy to loosen, ensure power and starting performance, and improve rotation effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

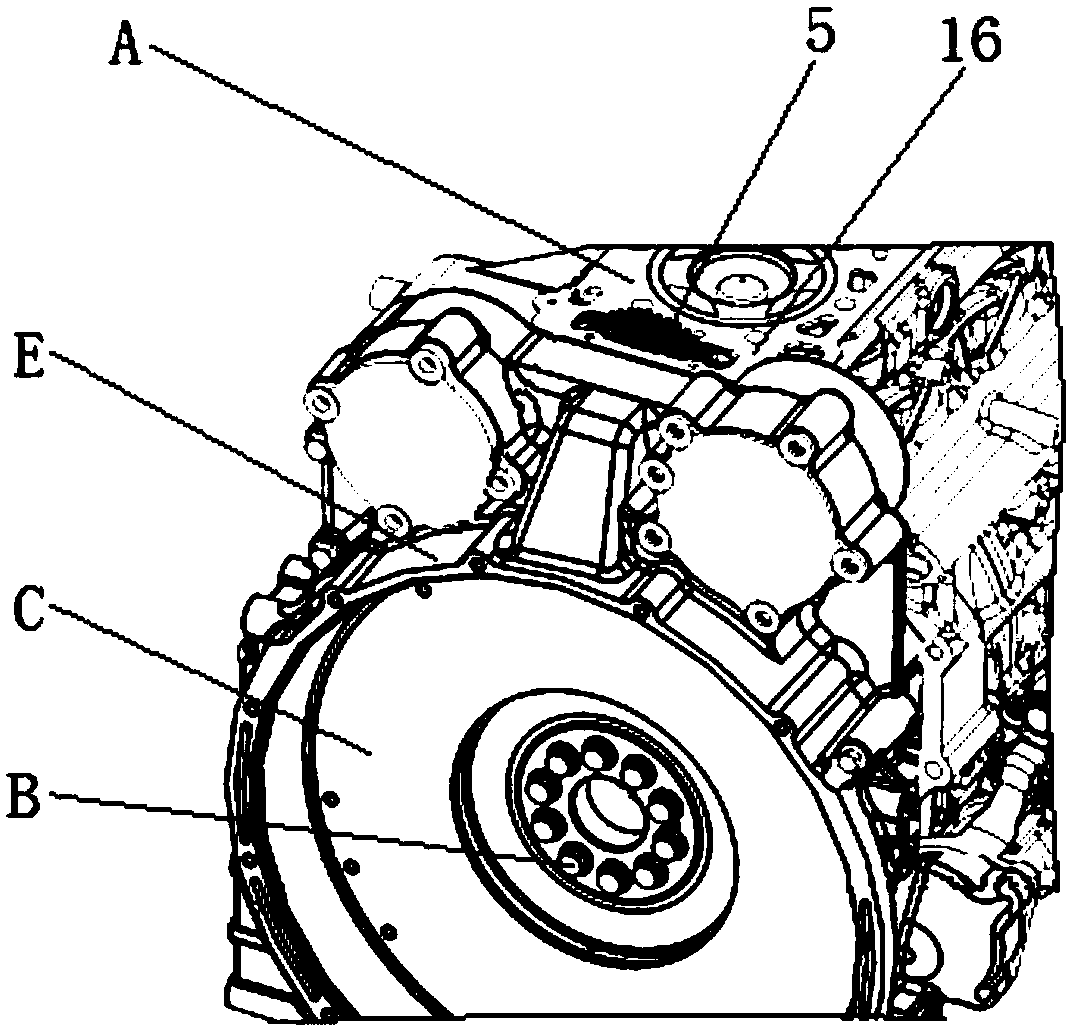

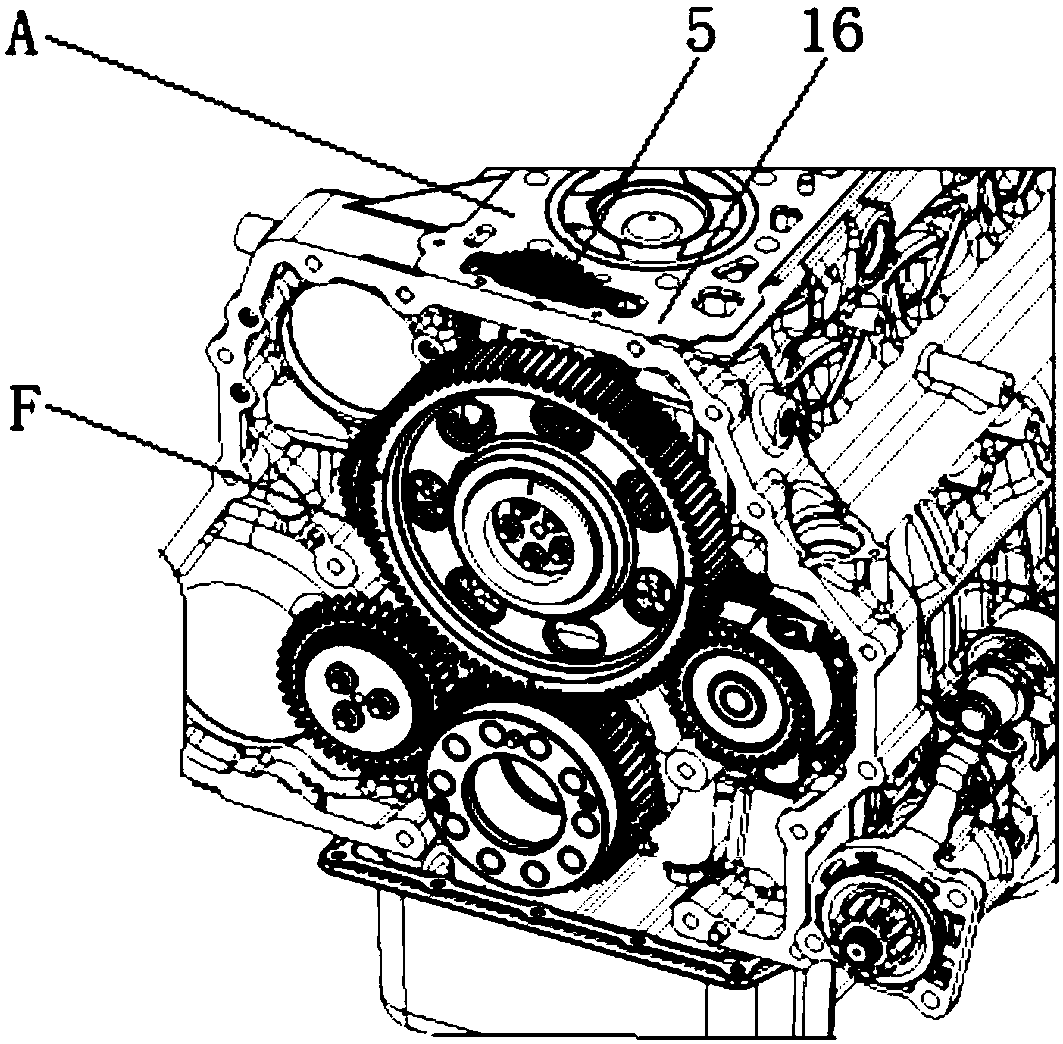

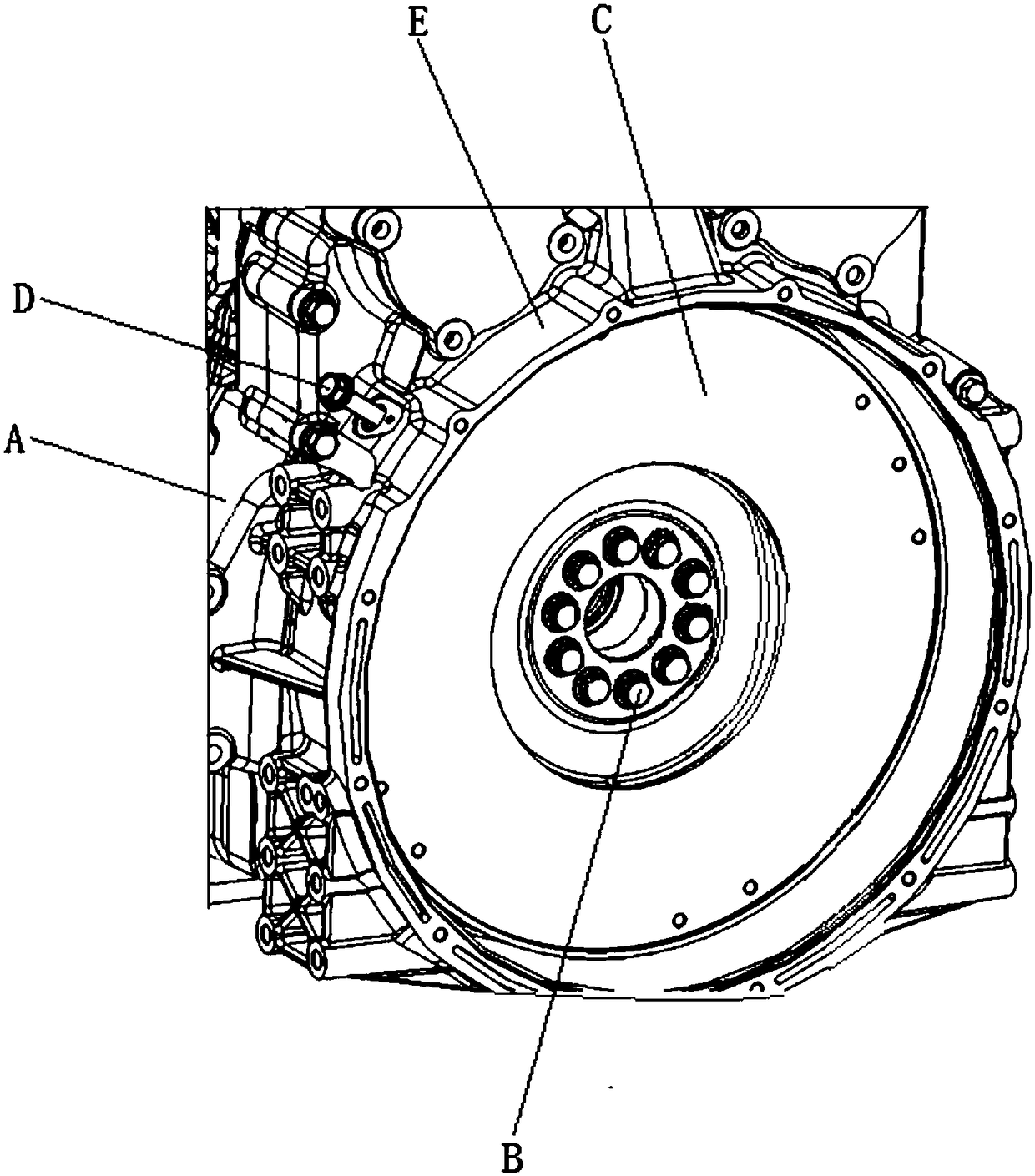

[0033] refer to Figure 1-12 , a tool for preventing the rotation of the flywheel of the rear power take-off engine, including a first bracket 1 and a second bracket 2 that can be folded or extended relatively, the first bracket 1 and the second bracket 2 can rotate relatively, and the first bracket 1 is provided with There is a first gear block 3 fixedly connected with it, and a second gear block 4 fixedly connected with it is provided on the second support 2, and the first support 1 includes a first step-off rod 7 connected sequentially from top to bottom, a first vertical Rod 8, first cross bar 9, correspondingly, second bracket 2 comprises the second give way bar 10, the second The vertical bar 11, the second cross bar 12, the upper end of the first give way bar 7 and the upper end of the second give way bar 10 are hinged to each other,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com