3D printer with nozzle cleaning function

A 3D printer and functional technology, applied in the field of 3D printers with nozzle cleaning function, can solve the problems of affecting the appearance of the model, discounting the cleaning effect, and waste filaments falling to the top of the printing platform, so as to improve cleaning efficiency, comprehensiveness, and cleaning effect Thorough, efficient cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

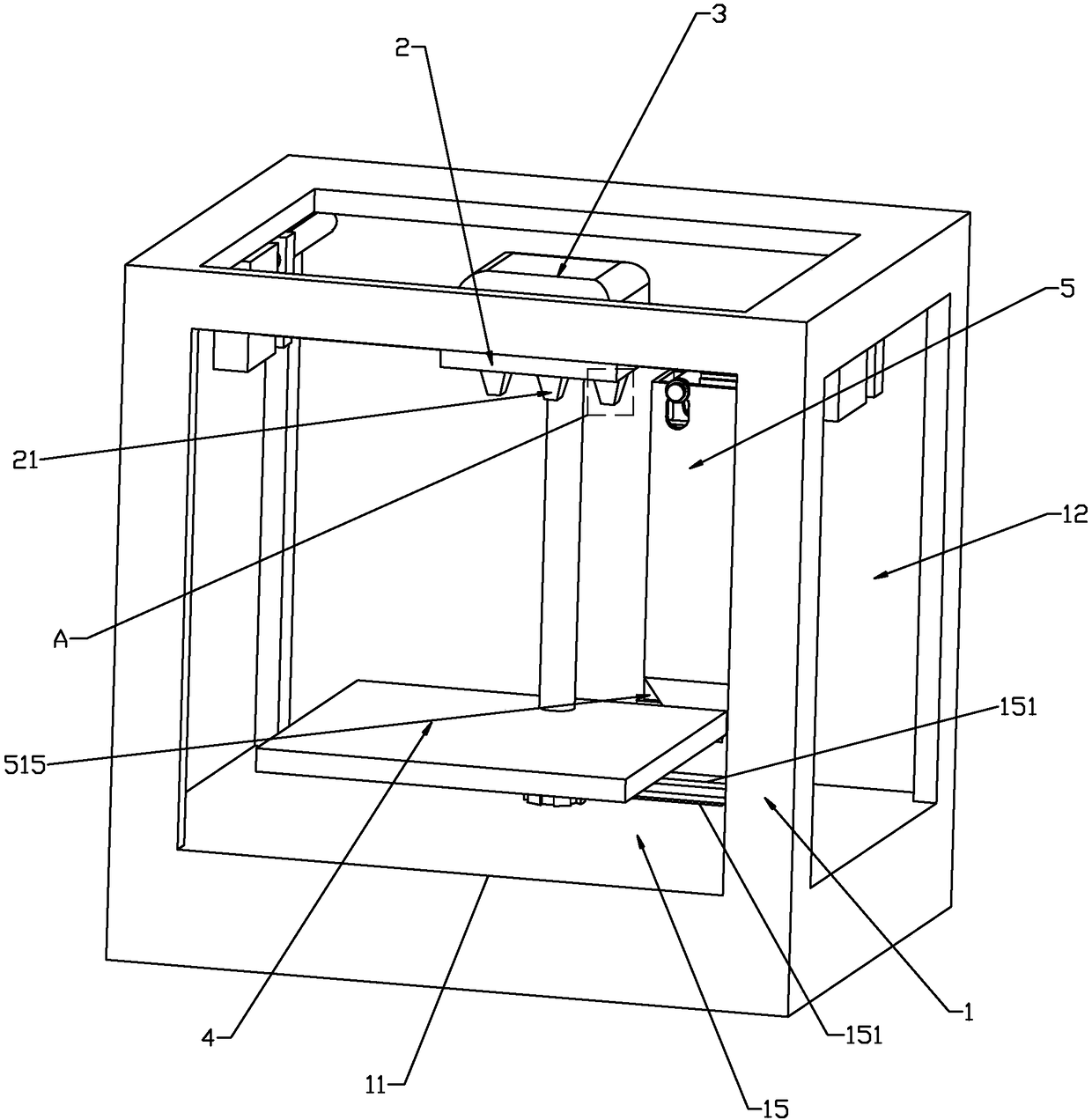

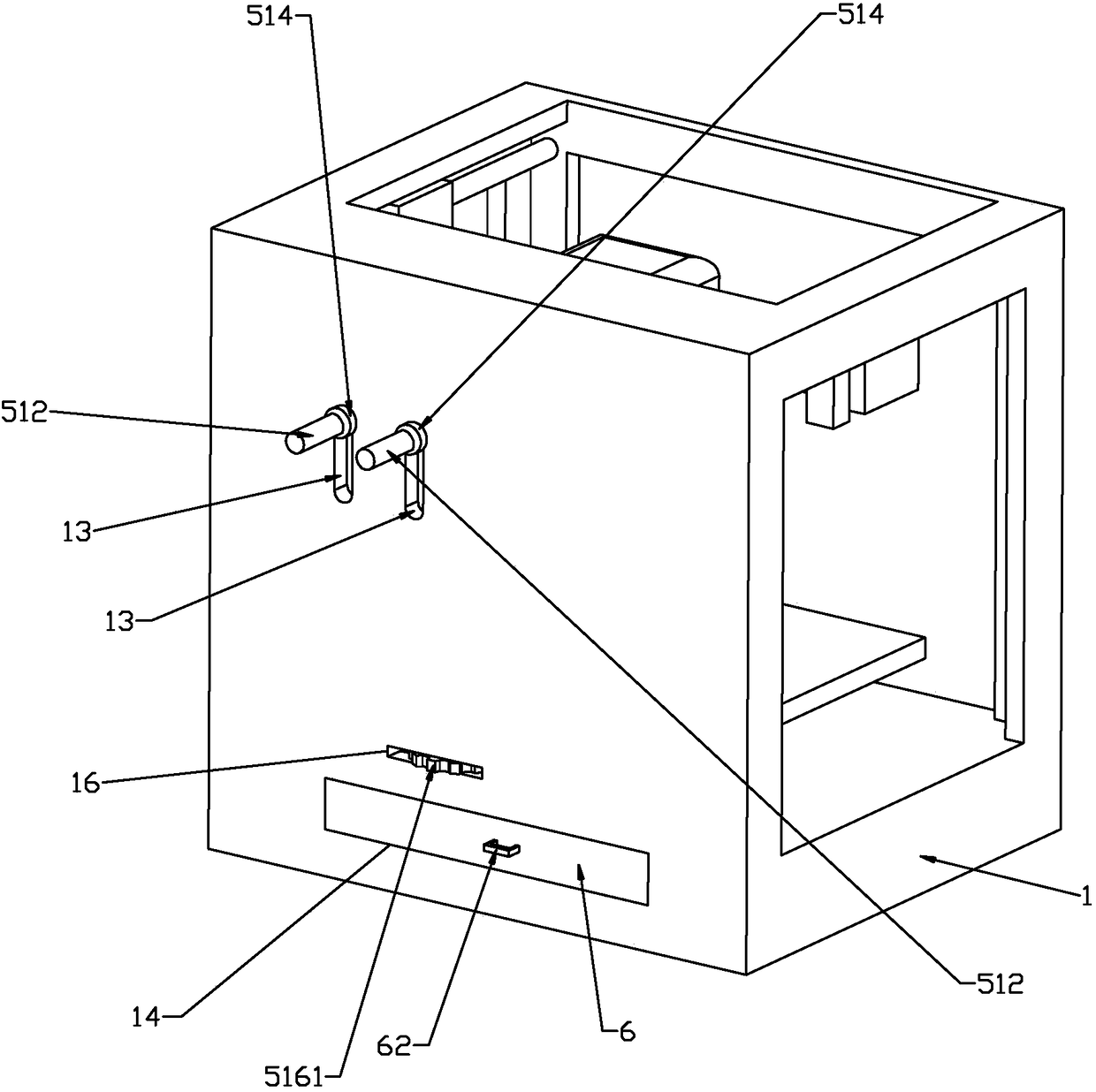

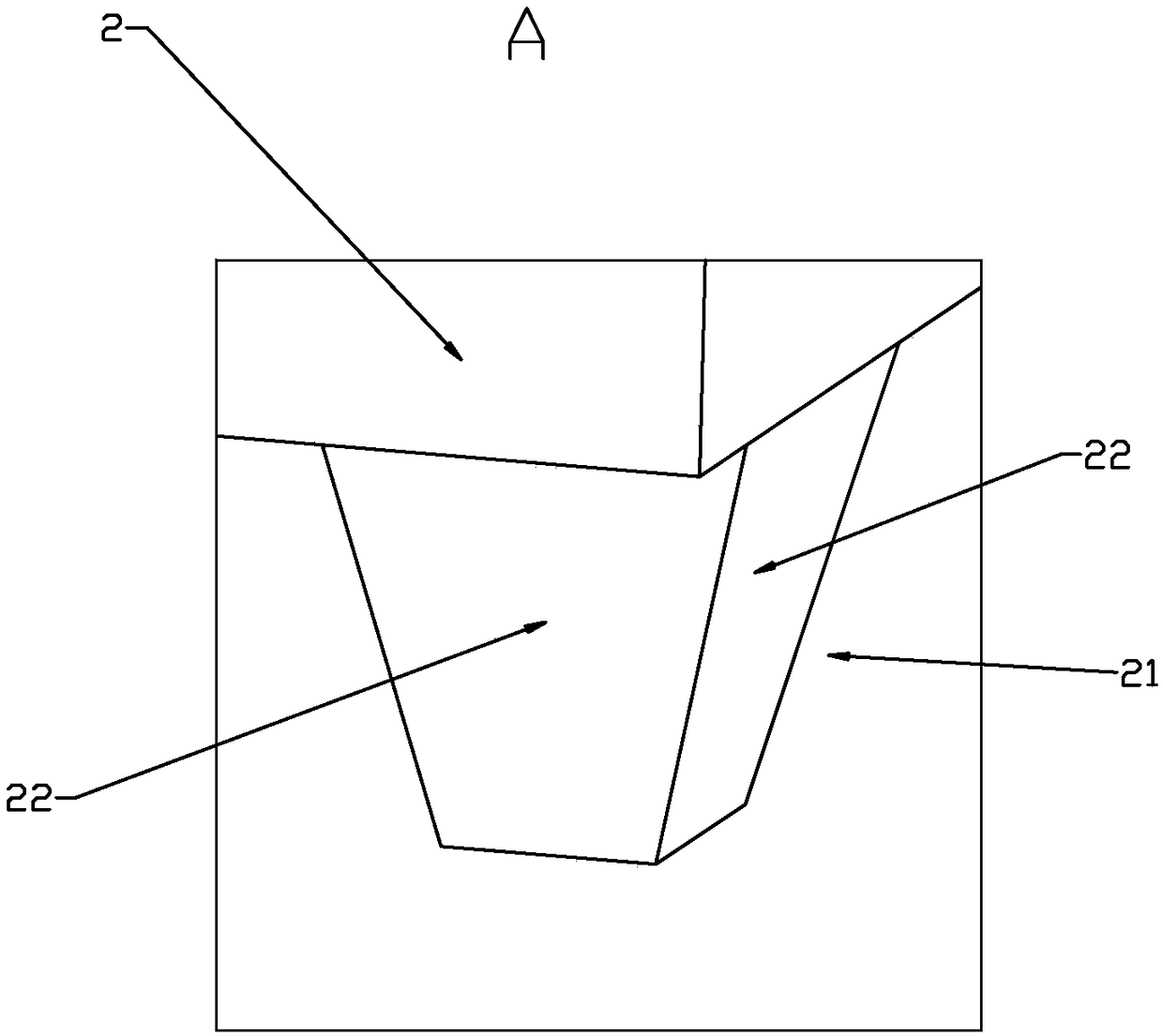

[0042] Such as figure 1 — Figure 8 As shown, the present invention discloses a 3D printer with a nozzle cleaning function, including a housing 1, a printing chamber 12 is arranged in the housing 1, an operation observation port 11 is arranged in front, and a 3D printing head 2 is arranged in the printing chamber 12. The moving device 3 that drives the 3D printing head 2 to move, the printing platform 4 used for printing material forming, and the cleaning device 5 for cleaning waste filaments, wherein the moving device 3 is an existing device, which can drive the printing head 2 along the X-axis and Y-axis and the Z-axis for three-dimensional movement. The 3D printing head 2 includes the printing nozzle 21 at the bottom and the heating mechanism surrounding the printing nozzle 21. The heating mechanism is an existing mechanism. , not shown in the accompanying drawings, but it does not affect the understanding of the structure, to ensure that the print head 2 can move to any p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com