Warm air blower circuit and cab warm air blower thereof

A heater and circuit technology, which is applied in railway car body parts, railway vehicle heating/cooling, transportation and packaging, etc., can solve the problems of inability to adjust the heating temperature, inability to effectively guarantee the electric heater, etc., and achieves low resistance and electric-heat conversion. High efficiency, no light loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

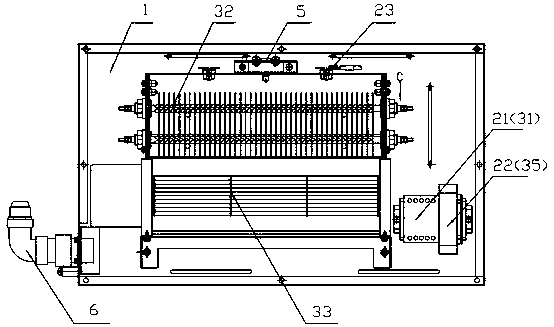

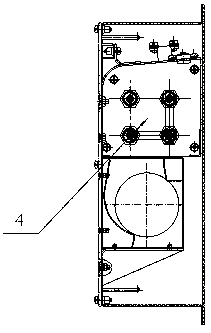

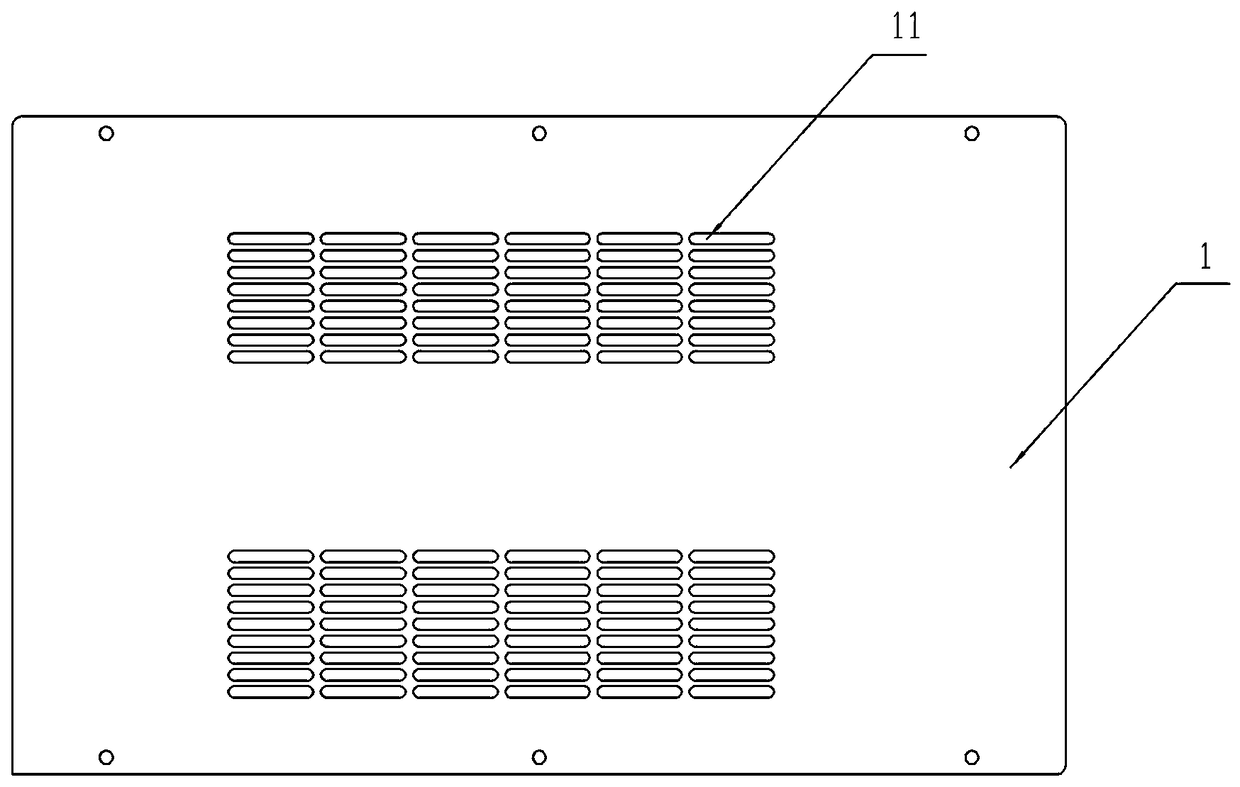

[0031] A cab heater, such as figure 1 As shown, including the chassis 1, the chassis 1 is equipped with such Figure 4 The heater circuit shown includes a control circuit 2 and a heating circuit 3, the control circuit 2 includes a contactor coil 21, the heating circuit 3 includes parallel heating branches and fan branches, and the heating branches include contactor contacts 31 and The heating element 32 is connected in series with the contactor contact 31 , and the fan branch circuit includes a fan 33 for dissipating the heat generated by the heating element 32 to the outside of the chassis 1 .

[0032] The contactor coil 21 and the contactor contacts 31 are an integral contactor. The power supply voltage connected to the control circuit 2 is 110V, and the power supply voltage connected to the heating circuit 3 is 220V. The wires in each circuit are centrally transferred into the chassis 1 through the connector 6. In this embodiment, the contactor is used to control the heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com