Internet-of-things-based intelligent integrated production equipment for detection and packaging of engineering tools and method of equipment

A technology of production equipment and the Internet of Things, applied in packaging, packaging protection, transportation and packaging, etc., can solve problems such as the inability to carry out efficient management of modern informationization, the impact of product transfer and workshop environment, and the impact of product quality stability, etc., to achieve Achieve timely circulation, realize information management, and save physical labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

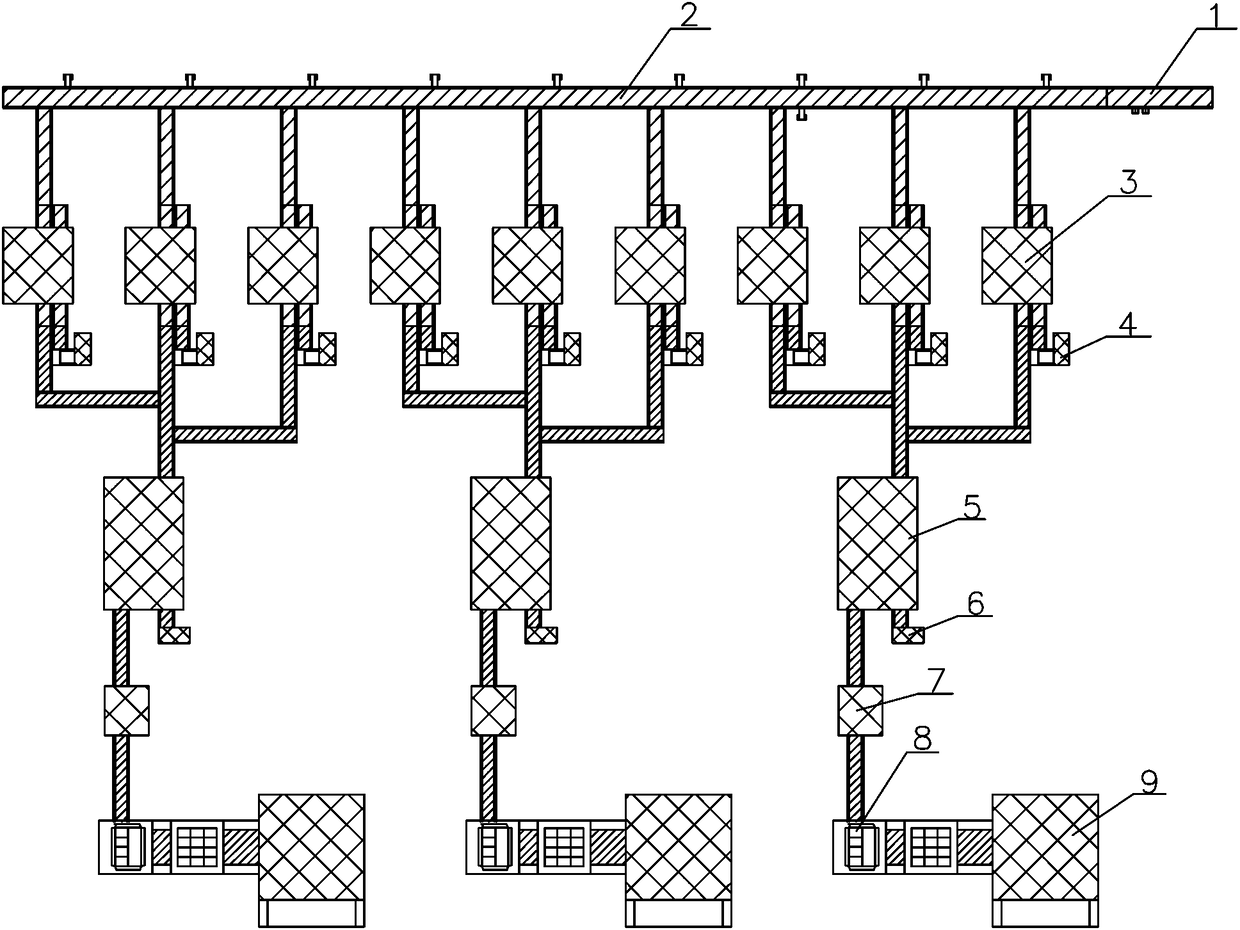

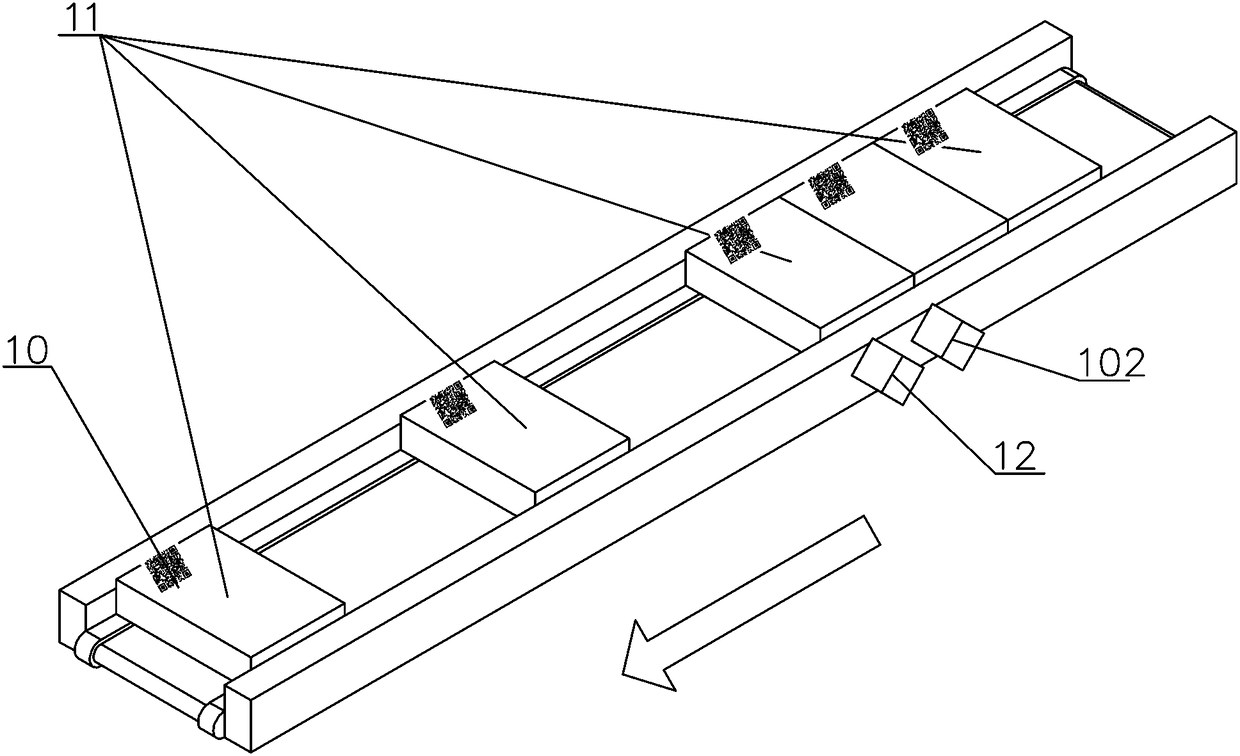

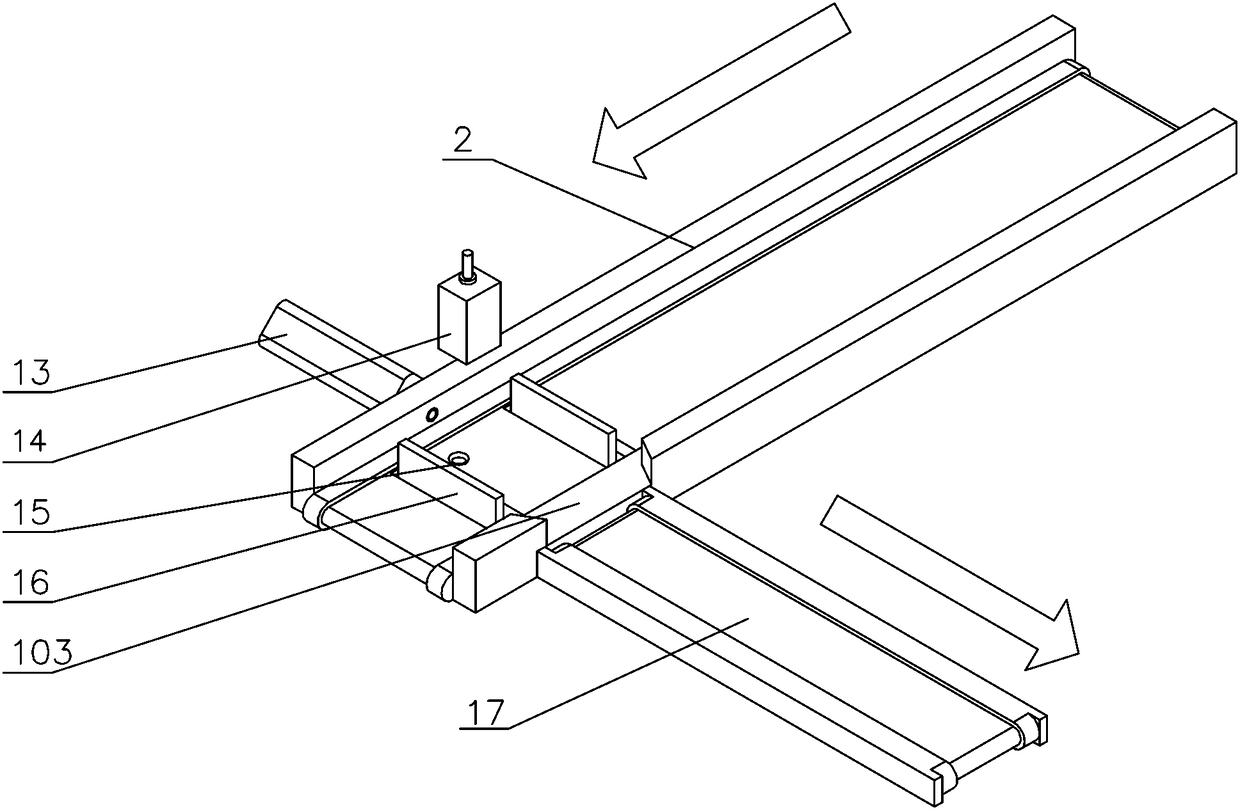

[0048] see Figure 1-8 , an intelligent integrated production equipment for engineering tool detection and packaging based on the Internet of Things, which includes a tool carrier plate 11 for placing a tool to be detected, and the tool carrier plate 11 is conveyed by an equidistant transmission belt 1, and the end of the equidistant transmission belt 1 It is connected with an identification transmission belt 2 for identifying different types of knives to be detected. The side of the identification transmission belt 2 is equipped with multiple groups of automatic detection machines 3 for quality inspection of different types of knives. The automatic detection machine 3 passes the transmission belt and the identification transmission belt 2 Connected, the discharge port of the automatic detection machine 3 is connected with the collar machine 5 for the tool collar through a transmission belt, the discharge port of the collar machine 5 is connected with the labeling machine 7 thr...

Embodiment 2

[0058] The tool detection and packaging method of any one of the IoT-based engineering tool detection and packaging intelligent integrated production equipment includes the following steps:

[0059] Step1: Classify and place the tools to be detected on the tool carrier disc 11 with the information code 10 attached, and then place the tool carrier disc 11 on the equidistant transmission belt 1;

[0060] Step2: When the irregularly placed tool carrier plate 11 on the equidistant transmission belt 1 passes the first in-position sensor 102, the fixed distance cylinder 12 is triggered, and the fixed distance cylinder 12 is pushed forward so that the tool carrier plate 11 on the track is fixed to the side. Make the follow-up tool carrier 11 close in turn, and then the fixed-distance cylinder 12 opens to release the front tool carrier 11, and the rear tool carrier 11 advances to the corresponding position and is fixed by the fixed-distance cylinder 12 again to the distance between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com