Millimeter level precisely positioning system for distance ranging of hoisting mechanism of tower crane

A hoisting mechanism and precise positioning technology, which is applied in cranes, load hanging components, transportation and packaging, etc., can solve the problems of mounting and hole positioning, and prevent positioning difficulties, reduce operation difficulty, and operate simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

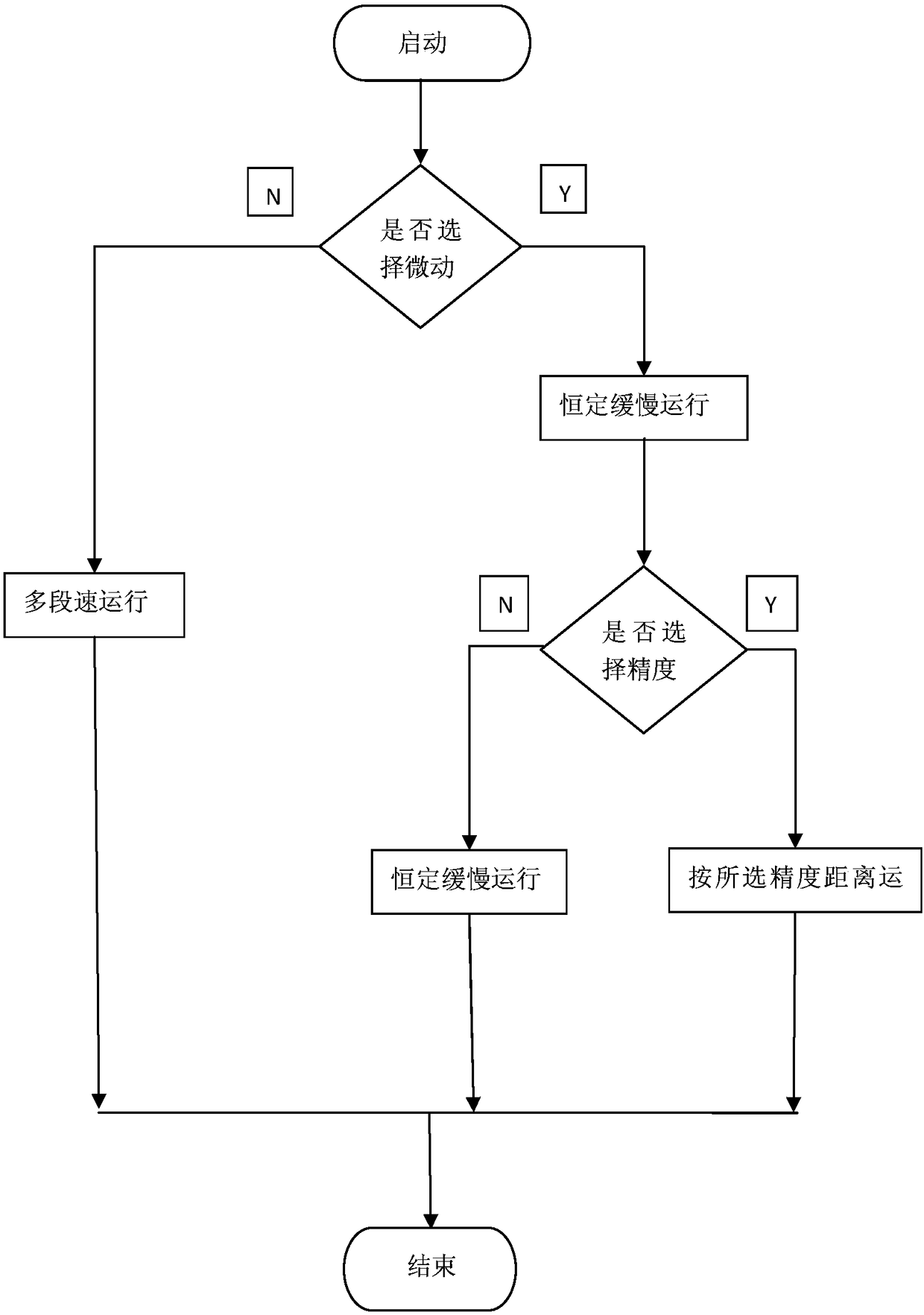

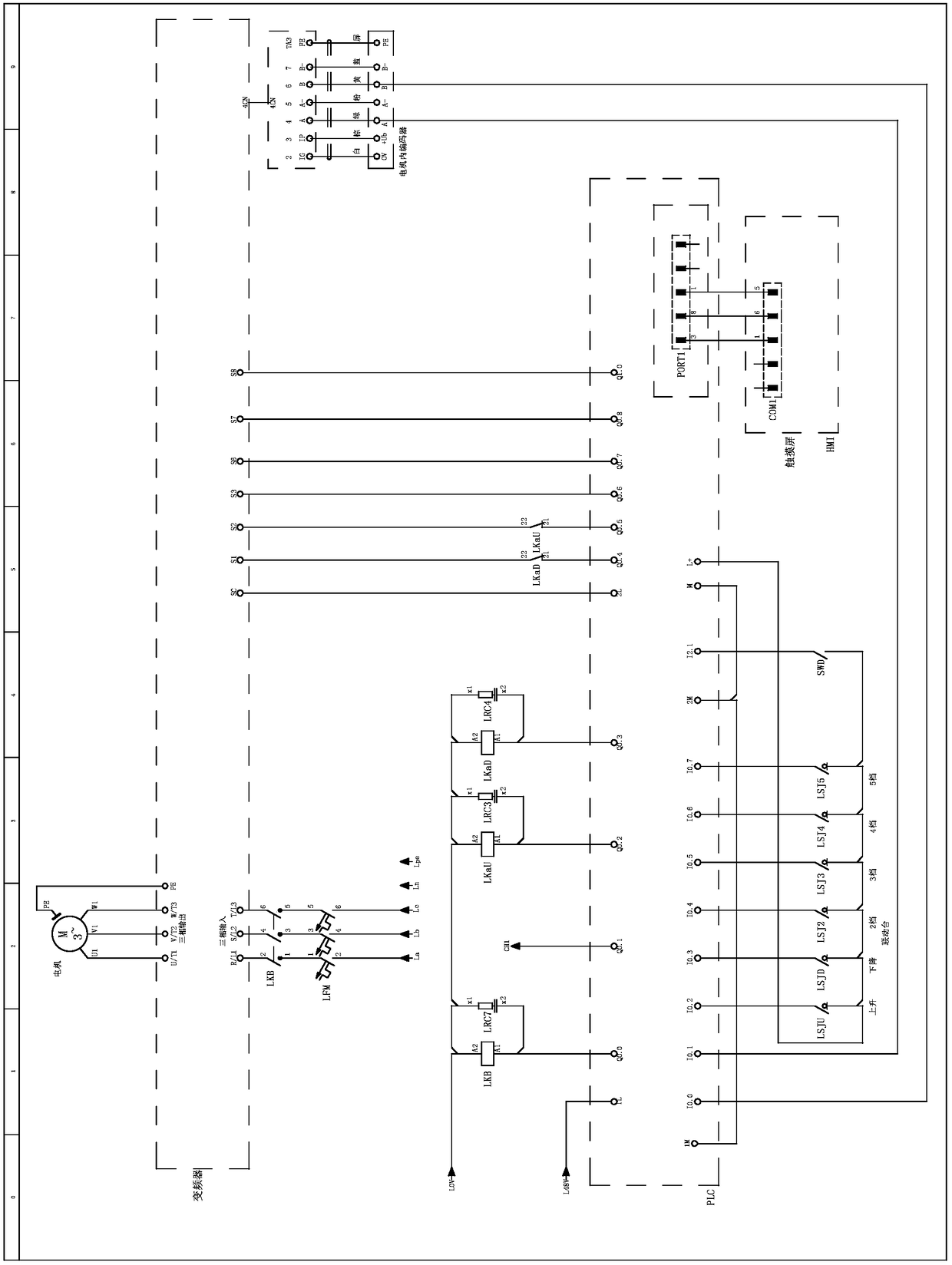

[0018] Below in conjunction with accompanying drawing, the present invention will be further described:

[0019] Such as Figure 1-3 As shown, a fixed-distance millimeter-level precise positioning system for the hoisting mechanism of a tower crane includes components such as a programmable controller, a frequency converter, a touch screen, an encoder, a control handle, and a control switch. The programmable controller is respectively connected to the control system, frequency converter, comparative analysis encoder and control switch, the frequency converter is connected to the hoisting mechanism of the tower crane, the programmable controller collects the instructions set by the touch screen and the control handle, and comparative analysis of the encoder The transmitted moving distance signal controls the operation and stop of the frequency converter, and realizes the millimeter-level precise positioning operation of the tower crane hoisting mechanism. The control system inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com