Brick-concrete integrated wall and obtaining method thereof

一种实现方法、墙体的技术,应用在墙、建筑构件、建筑等方向,能够解决制约产业发展、集成建筑产品单一化等问题,达到减少烦琐性、施工方法简单、强度好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The following is a detailed demonstration of what is described in the summary of the present invention, that is, examples of several specific implementation methods of the present invention are illustrated with reference to illustrations, so as to facilitate the understanding of those skilled in the art.

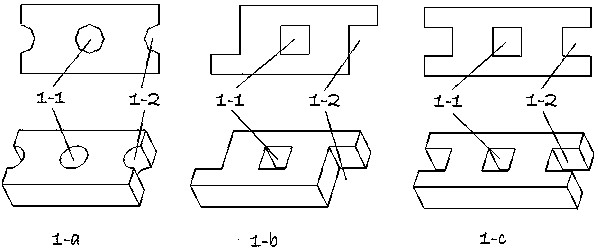

[0065] figure 1 Shown are several wall bricks involved in the present invention, including round hole wall brick 1-a, square hole wall brick 1-b, corner brick 1-c, and its structural feature is that the brick body includes a central hole 1-1 and side half hole 1-2, the size of body of wall brick, material and other structural characteristics, do not affect the enforcement of the present invention, promptly brick body can be clay brick or cement brick etc., and brick body structure can be only as The holes shown in the figure can also be porous hollow bricks, as long as the structural features shown in the figure are kept, the present invention can be implemented.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com