Prefabricated concrete wallboard with back-loaded decorative boards and manufacturing method thereof

A technology of prefabricated concrete and decorative panels, applied in building materials, building components, cladding/lining, etc., can solve the problems of easy shear deformation, heavy weight, thermal bridge and other problems of external wall panels, achieve light weight, reduce weight, avoid The effect of shear deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

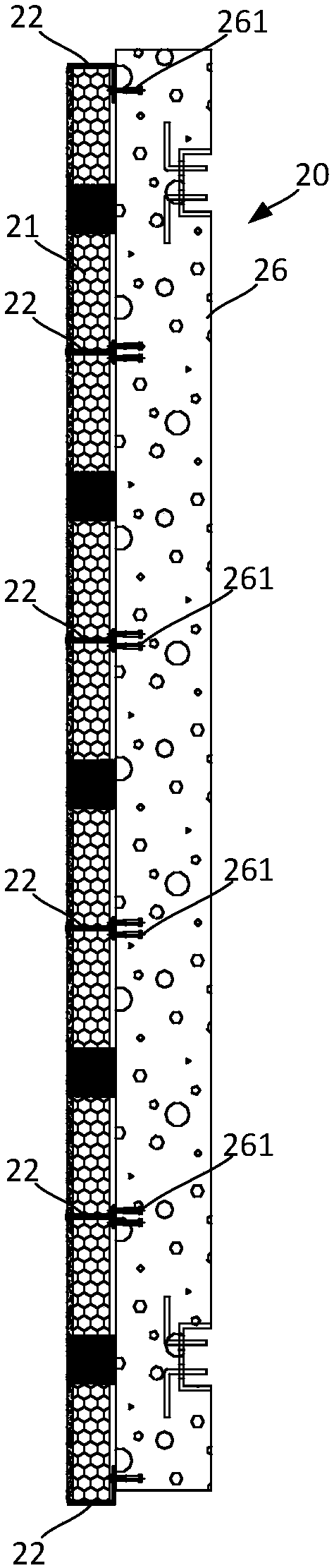

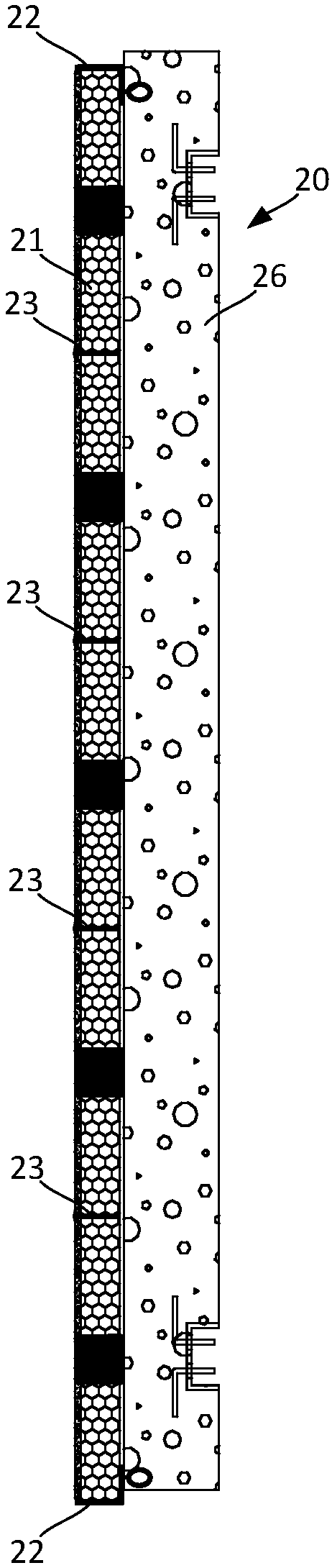

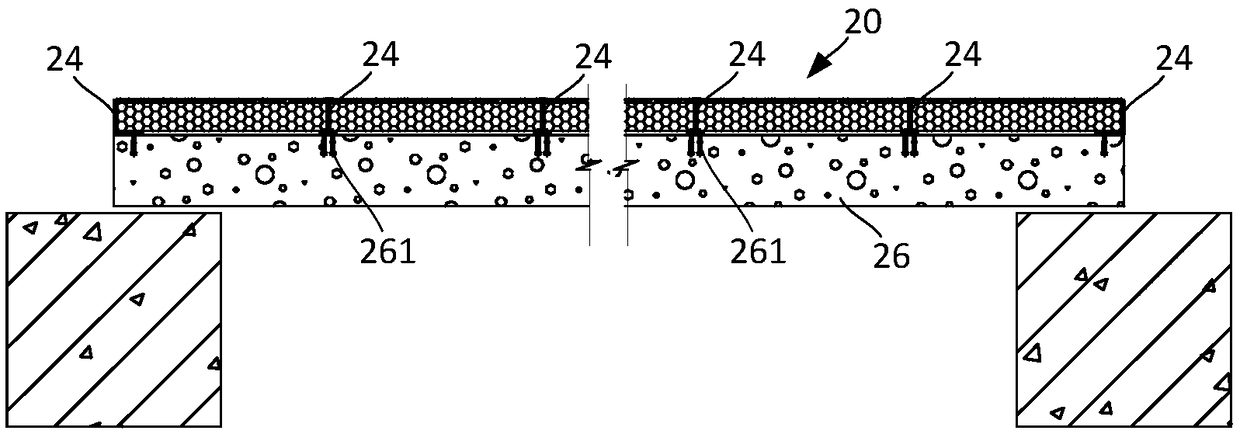

[0055] refer to figure 1 , the present invention provides a prefabricated concrete wall panel with post-installed decorative panels and a manufacturing method thereof. Compared with the existing concrete sandwich thermal insulation prefabricated wall panel, the precast concrete wall panel of the present invention is replaced by a decorative panel The outer leaf wall (that is, the outer wall panel) can reduce the weight of the prefabricated wall panel, and avoid the problem of shear deformation of the outer leaf wall after long-term use; The board filling reduces the thermal bridge effect of the board joints; the pallet assembly and the splint assembly adopt the form of combined plug-in connection, and the two plug-in connected parts are insulated by an insulating pad, which blocks the pallet assembly and the inter-assembly The thermal bridge e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com