Electronic control device for engineering machinery and working method

An electronic control device and construction machinery technology, applied in the direction of engine motor starting, electrical control, mechanical equipment, etc., can solve the problems of no safety protection measures for the engine, damage to the engine and supercharger, damage to the starter and the battery, etc., to achieve Protect the starter and battery, avoid dangerous events, and ensure the safety and reliability of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

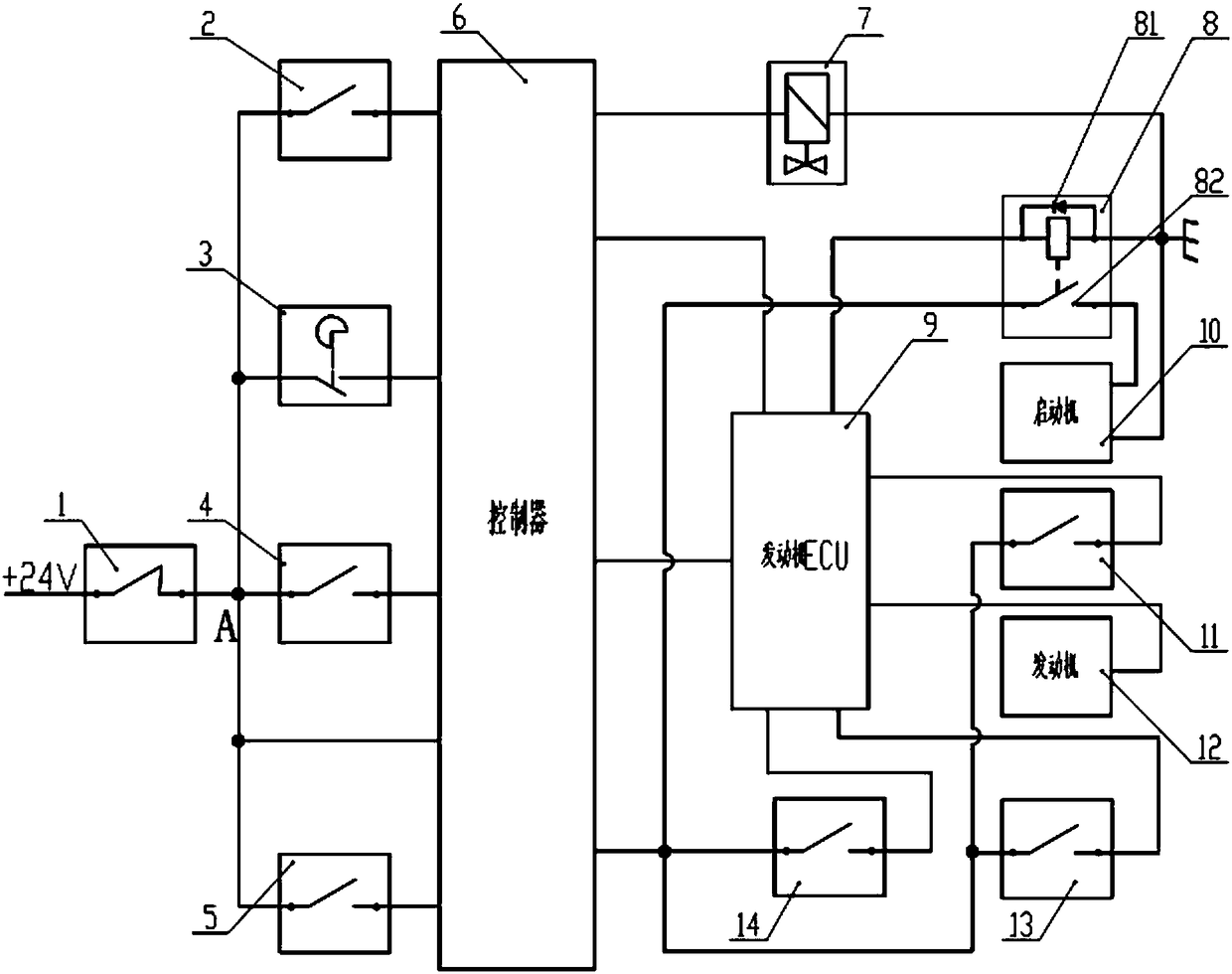

[0030] like figure 1 As shown: the invention discloses an electric control device for construction machinery, including a parking brake switch 2, a handle neutral switch 3, an accelerator idle switch 4, a start switch 5, a controller 6, a start relay 8, an engine ECU 9, Starter 10, flameout switch 11, start relay 8 includes start relay coil 81 and start relay contact 82, parking brake switch 2, handle neutral switch 3, throttle idle switch 4, start switch 5, and controller 6 all pass through Pin A is connected to the power supply, the controller 6 is connected to the parking brake switch 2, the handle neutral switch 3, the throttle idle switch 4, the start switch 5, the start relay contact 82, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com