Normally-closed air inlet valve of air compressor

A technology of air compressors and intake valves, which is applied in mechanical equipment, machines/engines, and liquid displacement machinery, etc., and can solve problems such as complex air supply methods of intake valves, poor sealing performance of intake valves, and complex structures , to achieve significant effects of pressure relief and air supplementation, ensure oil circulation, and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment, the specific embodiment of the utility model is described in further detail. The following examples are used to illustrate the utility model, but not to limit the scope of the utility model.

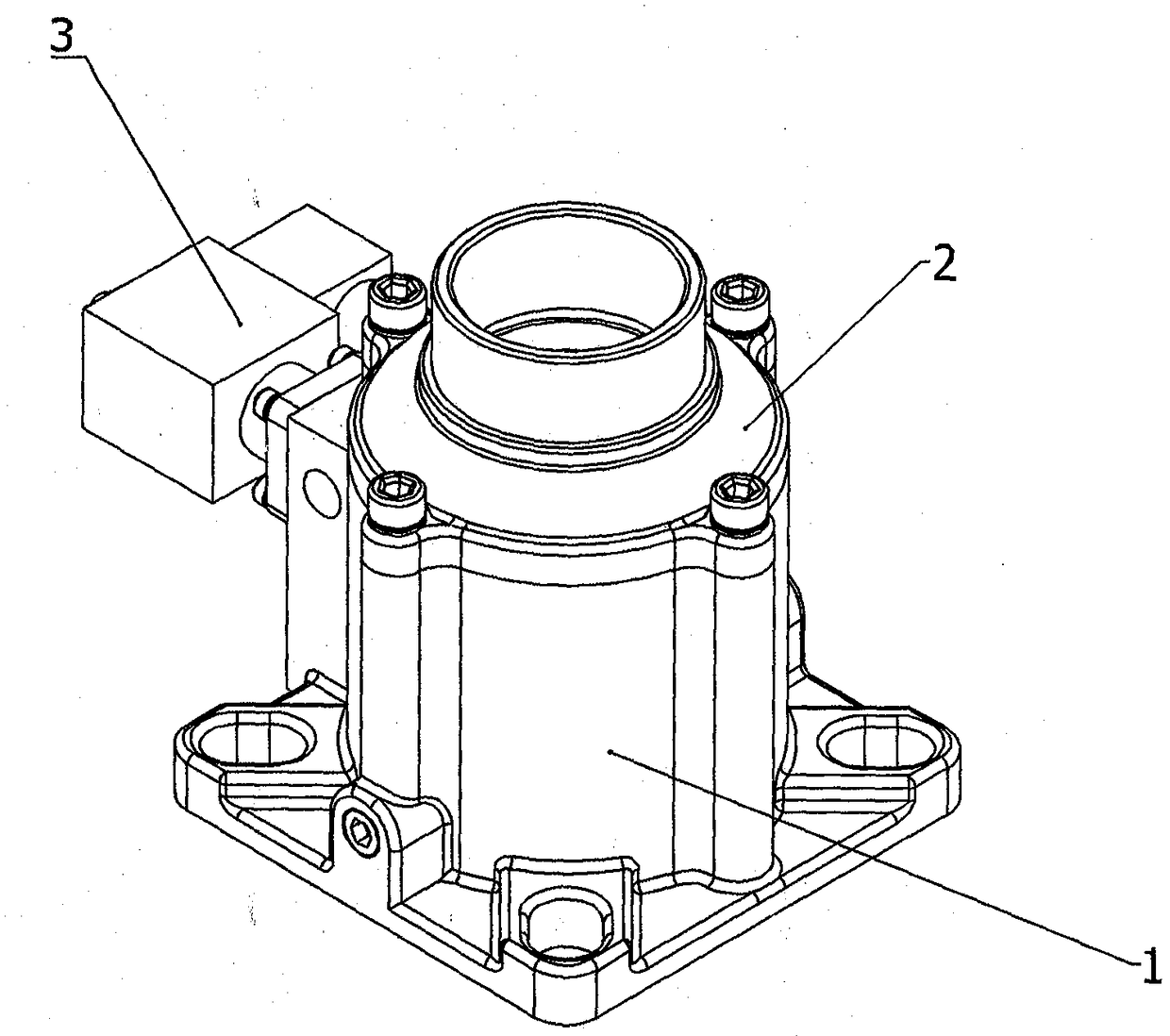

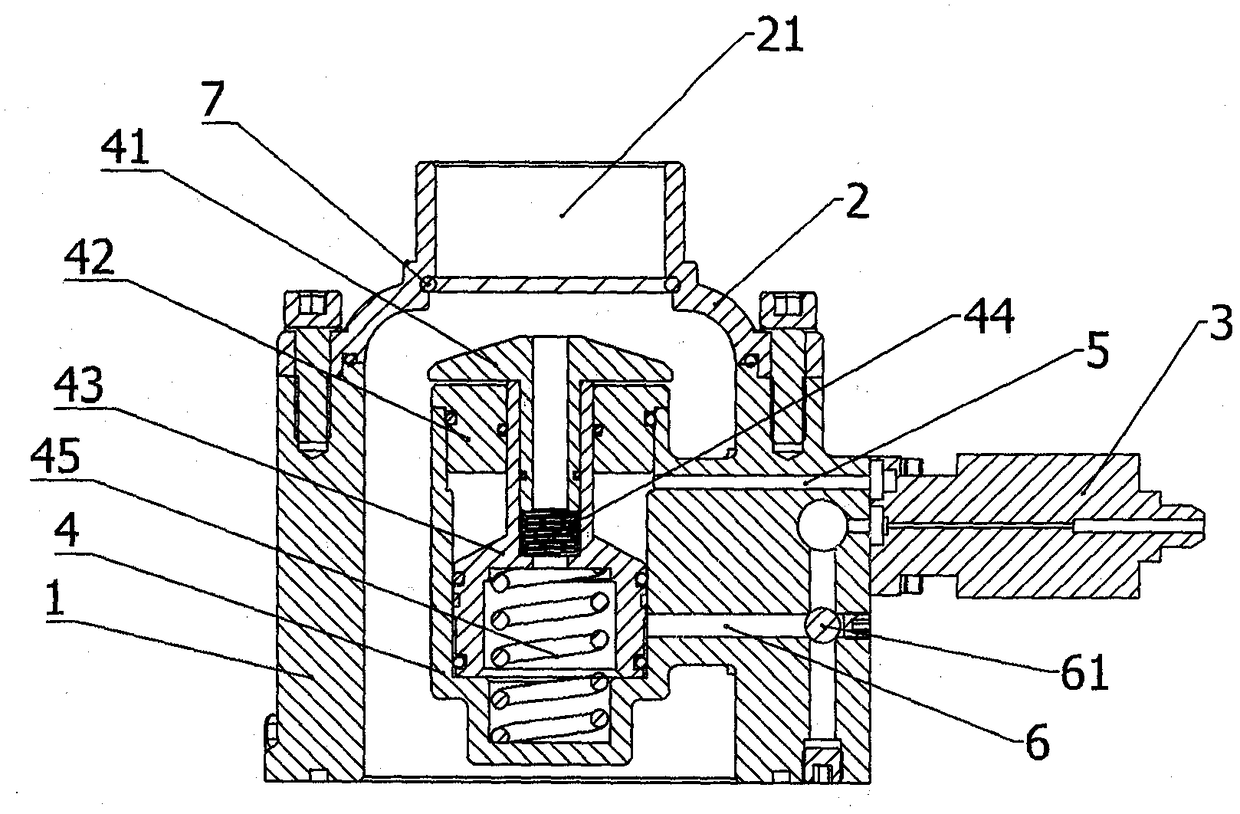

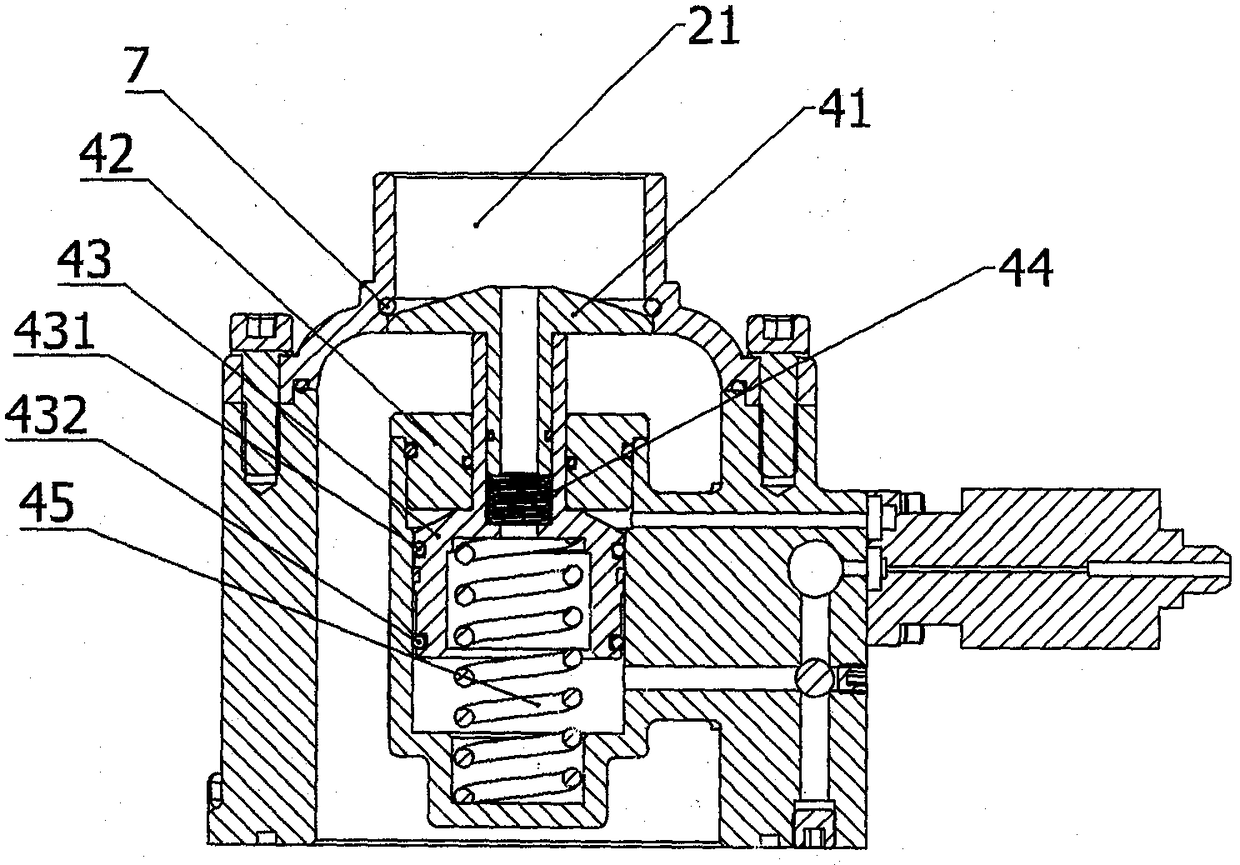

[0017] Combine below Figure 1 to Figure 5 To describe in detail the utility model, a normally closed intake valve of an air compressor includes a valve body 1, and the valve body 1 is provided with a pressure inlet 5, a pressure relief hole 6 and a cavity 4 in the valve body, The pressure inlet hole 5 is connected with a gas pipeline interface, and the valve body 1 is fixedly connected with an upper cover body 2 by bolts, and the upper cover body 2 is provided with an air inlet hole 21, which is characterized in that: the cavity body 4 A piston 43 is arranged in the cavity, a piston cap 42 is fixedly connected to the opening end of the cavity 4, and the piston 43 is slidably arranged relative to the piston cap 42, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com