Interlockable lock bolt and nut

A technology of anti-loosening bolts and nuts, which is applied in the field of fixing components and components that often vibrate, and can solve the problems of inconvenient manufacture, use, and non-interlocking of anti-loosening nuts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

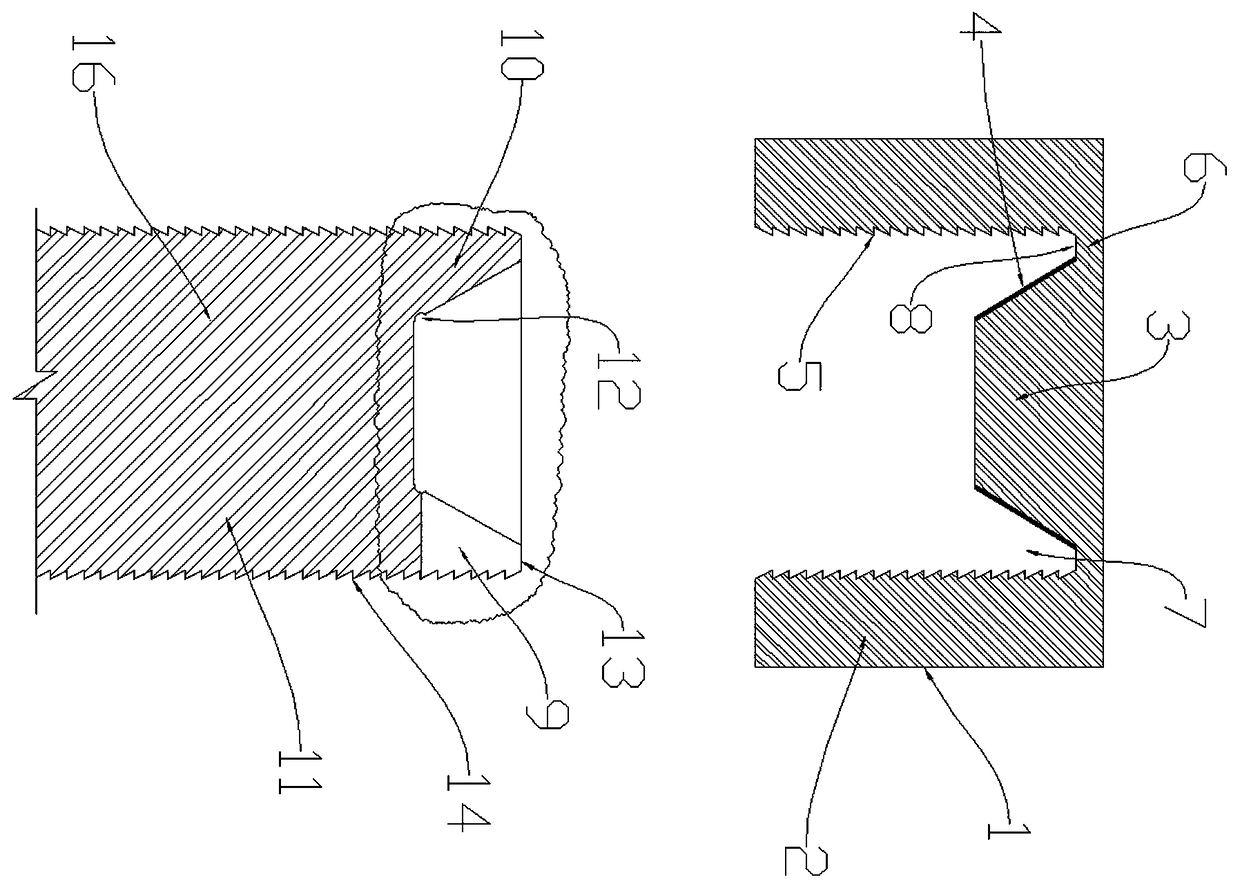

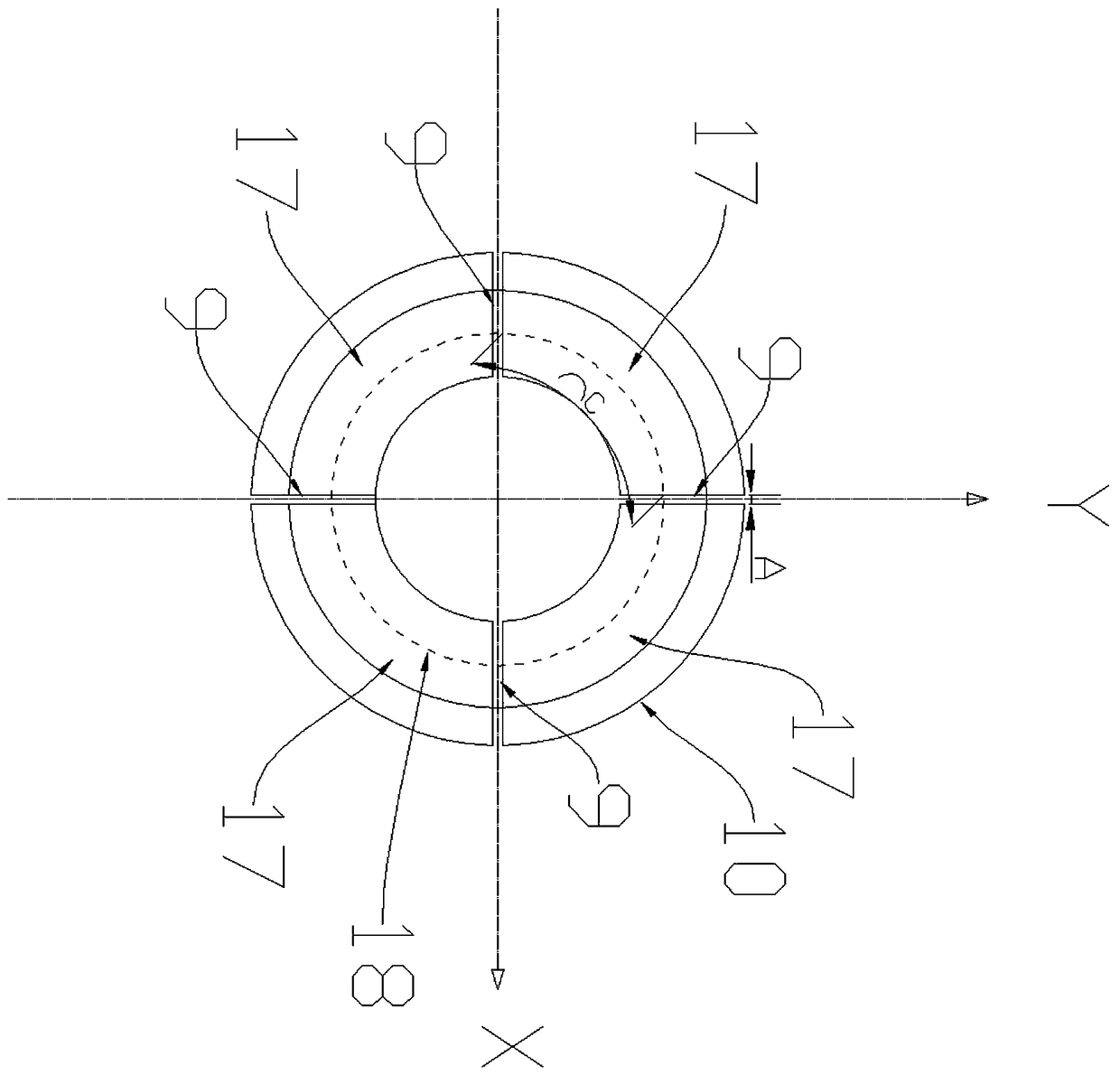

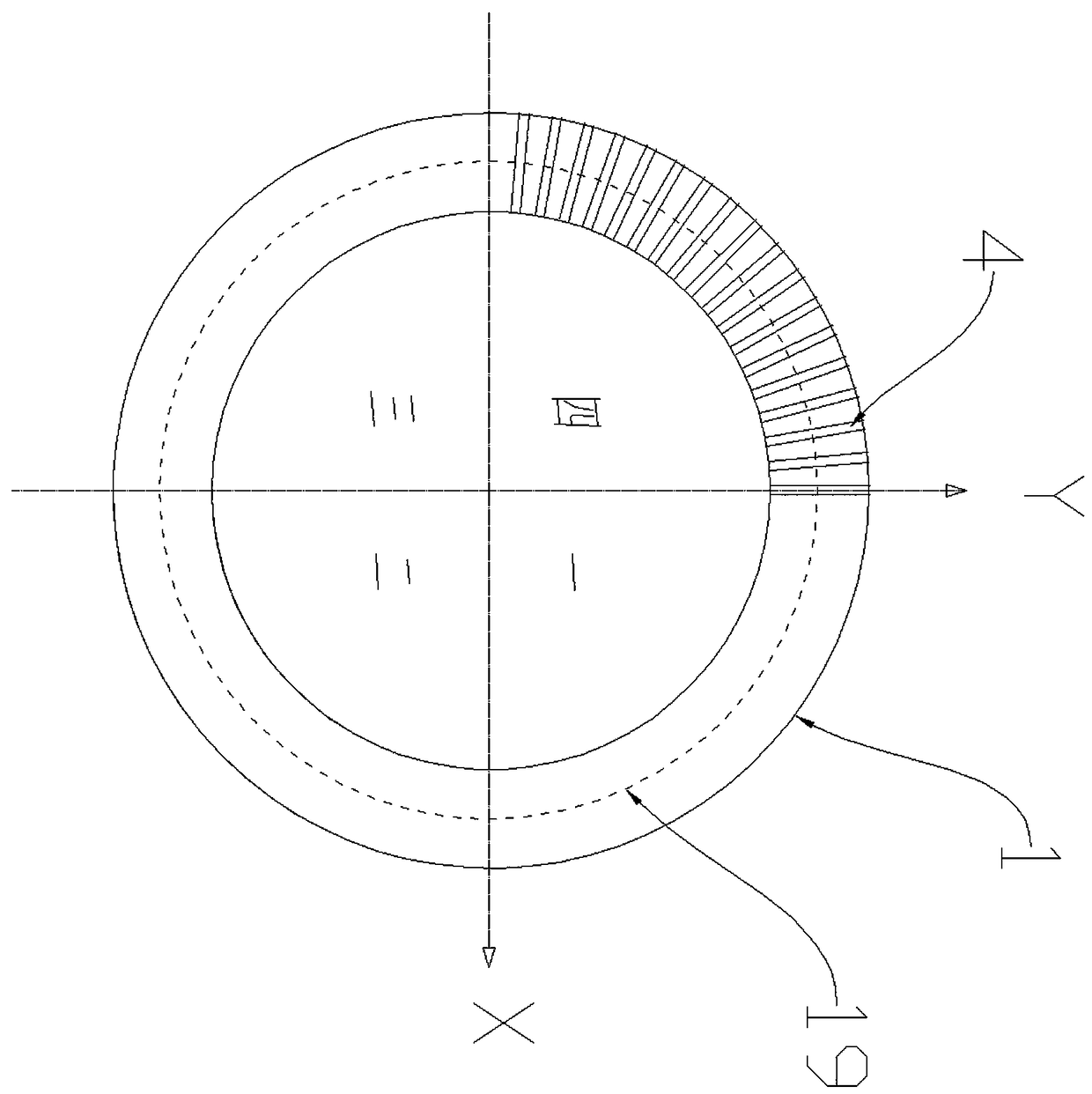

[0016] see Figure 1 to Figure 11 , first explain the arrangement of a plurality of strip-shaped ribs 4 of the nut 1, assuming that the number of clips 17 of the bolt 16 is N, and N is an even number, the number of the same groove 9 is also N, and the width of the groove 9 is A. The radius of the imaginary circle A18 of the center point of the inner surface of the frustum of a cone formed by two clips 17 is R, and the average arc length of each clip 17 is C, then C=2∏R / N-A, and it is assumed that the nut 1 The outer surface of the truncated cone of the extrusion part 3 is arranged within the range corresponding to the arc length C of the clip 17. M convex ribs 4 are arranged, and the virtual circle B19 of the upper and lower center points on the outer surface of the truncated cone of the extrusion part 3 of the nut 1 The radius is R', when the nut 1 and the bolt 16 are processed, R=R', although R=R' here, when the multiple strip-shaped ribs 4 of the extruded part 3 of the nut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com