3-gear double-clutch automatic gearbox for motor electromobile

An automatic transmission and clutch technology, which is applied to vehicle gearboxes, multi-gear ratio transmissions, transmission elements, etc., can solve the problems of insufficient strength, small diameter of the second input solid shaft, difficult to load large torque, etc., to ensure safety. and comfort, guaranteeing process feasibility, reducing the effect of specification cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the present invention more obvious and understandable, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

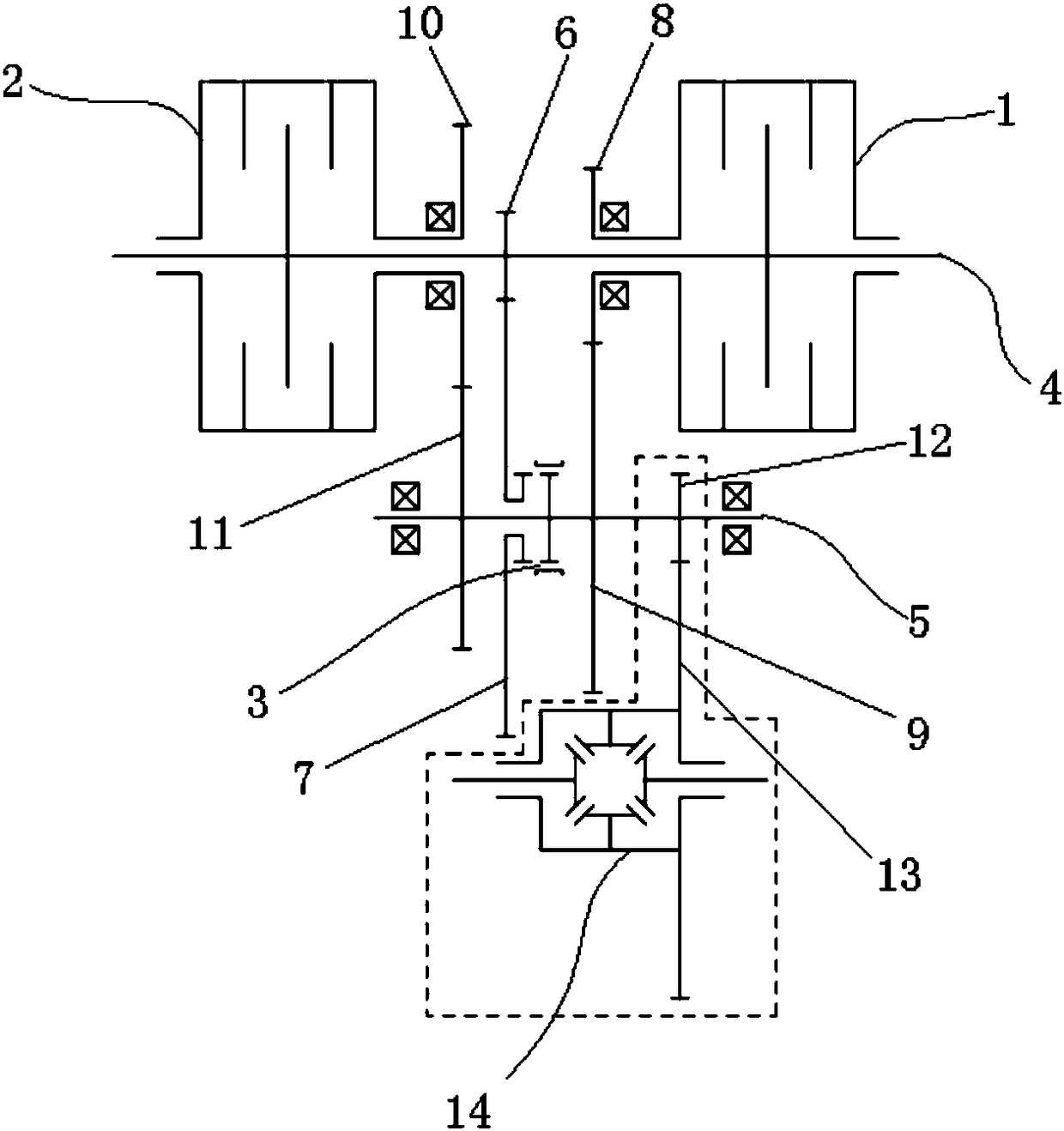

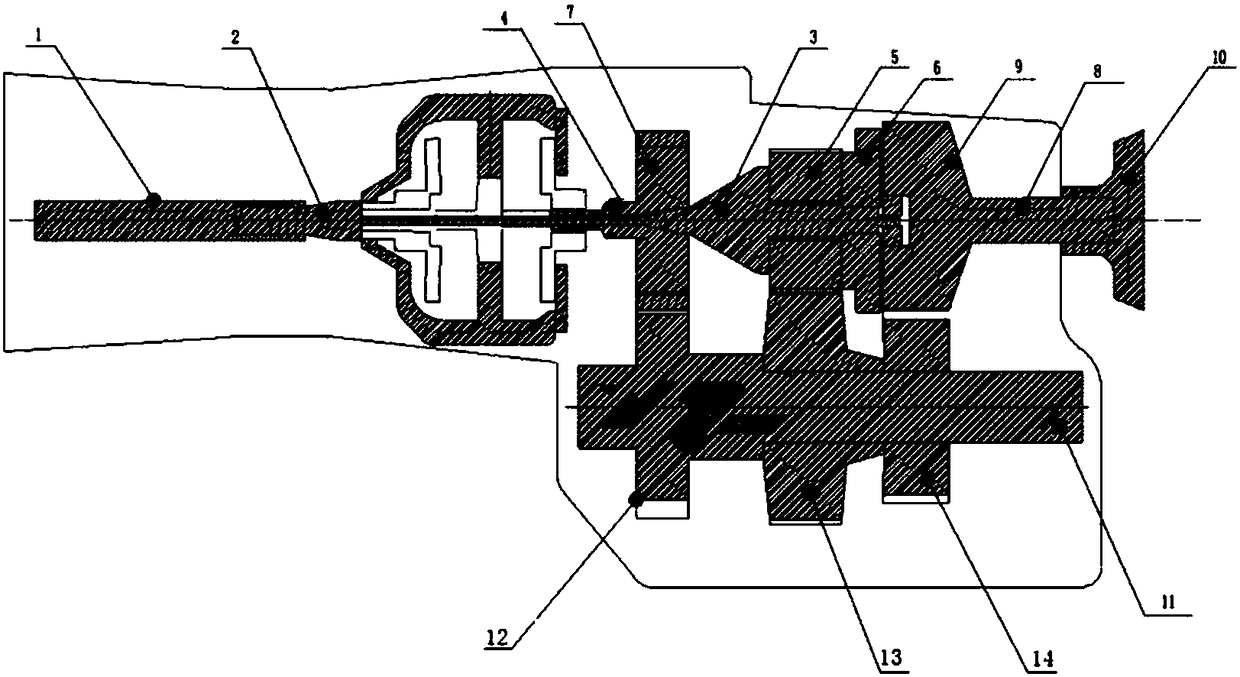

[0019] like figure 1 As shown, a 3-speed dual-clutch automatic transmission for a load-bearing electric vehicle includes a clutch K11, a clutch K22, a synchronizer 3, an input shaft 4 arranged in parallel, a second shaft 5, a first-speed gear pair, a second-speed gear pair and a third gear pair. The clutch K1 and the clutch K2 are arranged at both ends of the input shaft, the clutch K1 transmits power to the second shaft through the second gear pair, and the clutch K2 transmits power to the second shaft through the The third-gear gear pair transmits power to the second shaft; the first-gear gear pair includes a first-gear driving gear 6 and a first-gear passive gear 7 meshing with the first-gear driving gear, and the first-gear driving gear is fixed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com