Double inner cylinder self-sealing rotating compensator

A rotary compensator and self-sealing technology, which is used in expansion compensation devices for pipelines, pipes/pipe joints/fittings, adjustable connections, etc., can solve the problem of large space, reduced sealing performance of rotary compensators, and easy wear of sealing packing. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

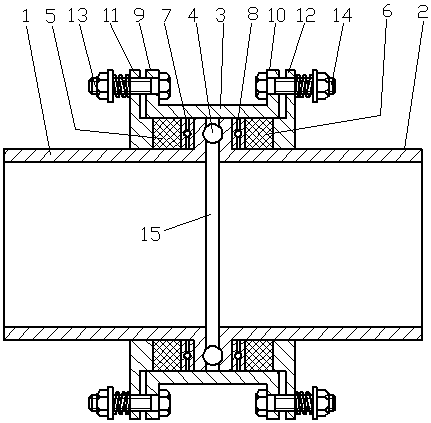

[0009] The specific embodiment of the present invention will now be described in conjunction with the accompanying drawings.

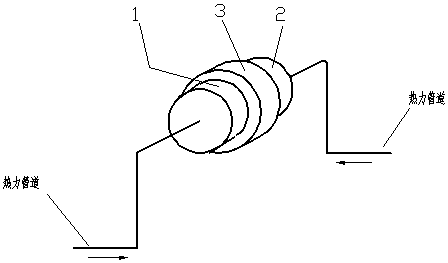

[0010] A double-inner cylinder self-sealing rotary compensator, which includes an outer cylinder 3, characterized in that a first inner cylinder 1 is inserted in the left section of the outer cylinder, a second inner cylinder 2 is inserted in the right section of the outer cylinder, and the first inner cylinder 2 is inserted in the right section of the outer cylinder. The outer diameter of the flange at the right end of the cylinder matches the inner circle of the outer cylinder, the outer diameter of the flange at the left end of the second inner cylinder matches the inner circle of the outer cylinder, and the flange of the first inner cylinder matches the inner circle of the second inner cylinder. Spherical recesses are arranged symmetrically on the end faces facing each other, steel balls 4 are arranged between the spherical recesses, the flange end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com