Sensor screw lifting mechanism for ocean buoy monitoring system

A monitoring system and screw lifting technology, applied in the direction of instruments, testing water, supporting machines, etc., can solve the problems of unsatisfactory cleaning, narrow application scope, high rigidity requirements, low cost, avoid secondary damage, and construction cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

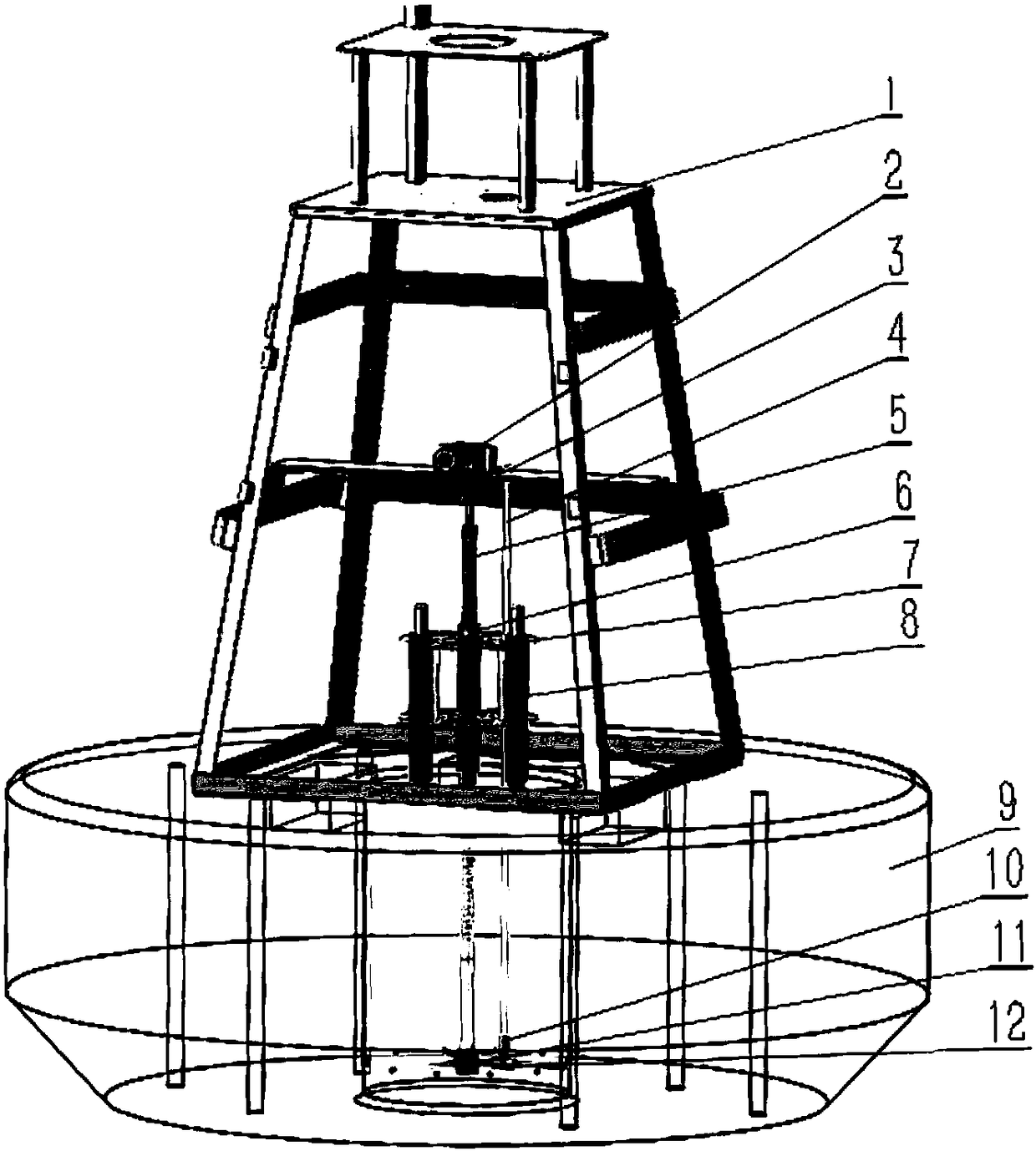

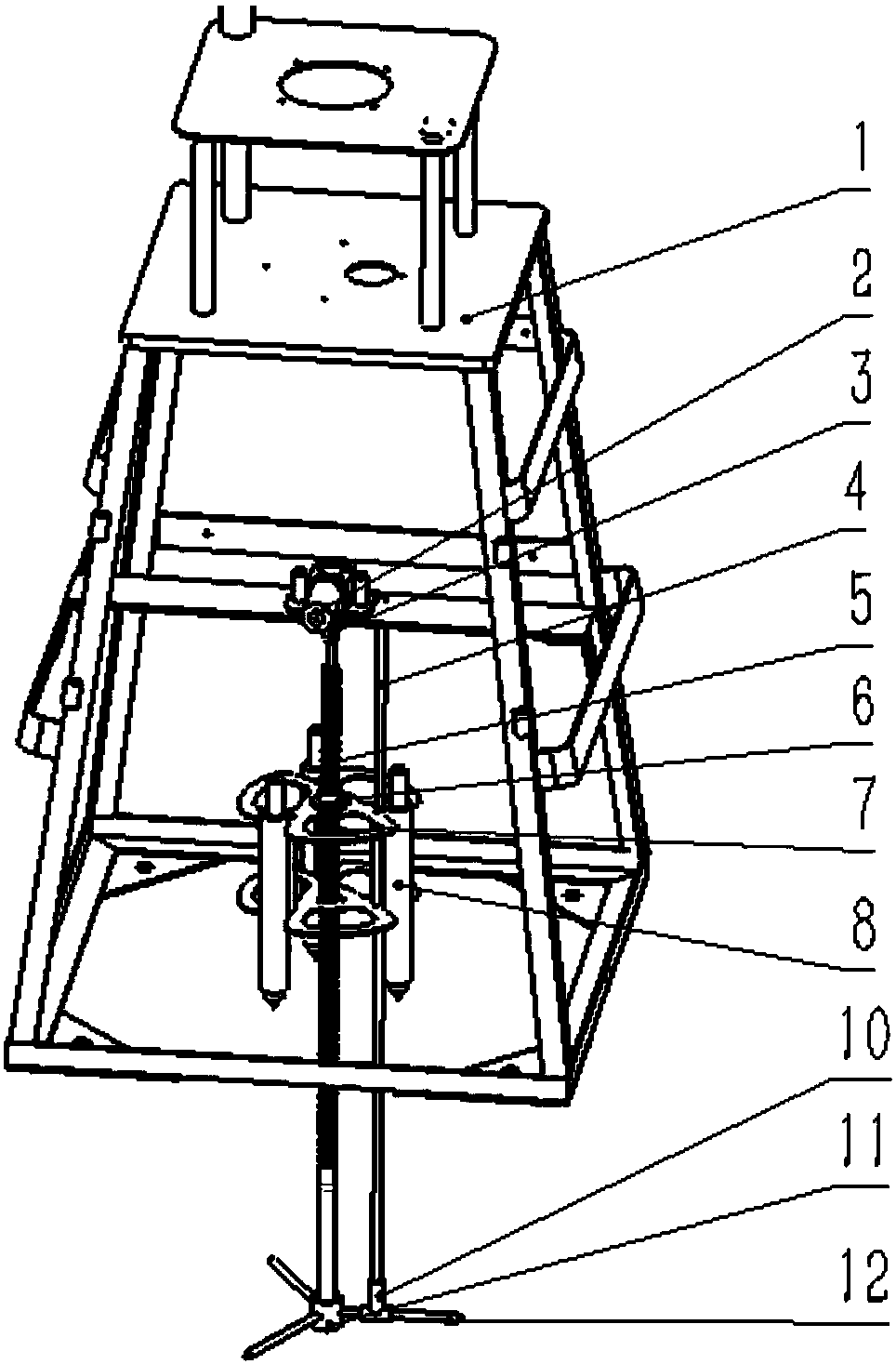

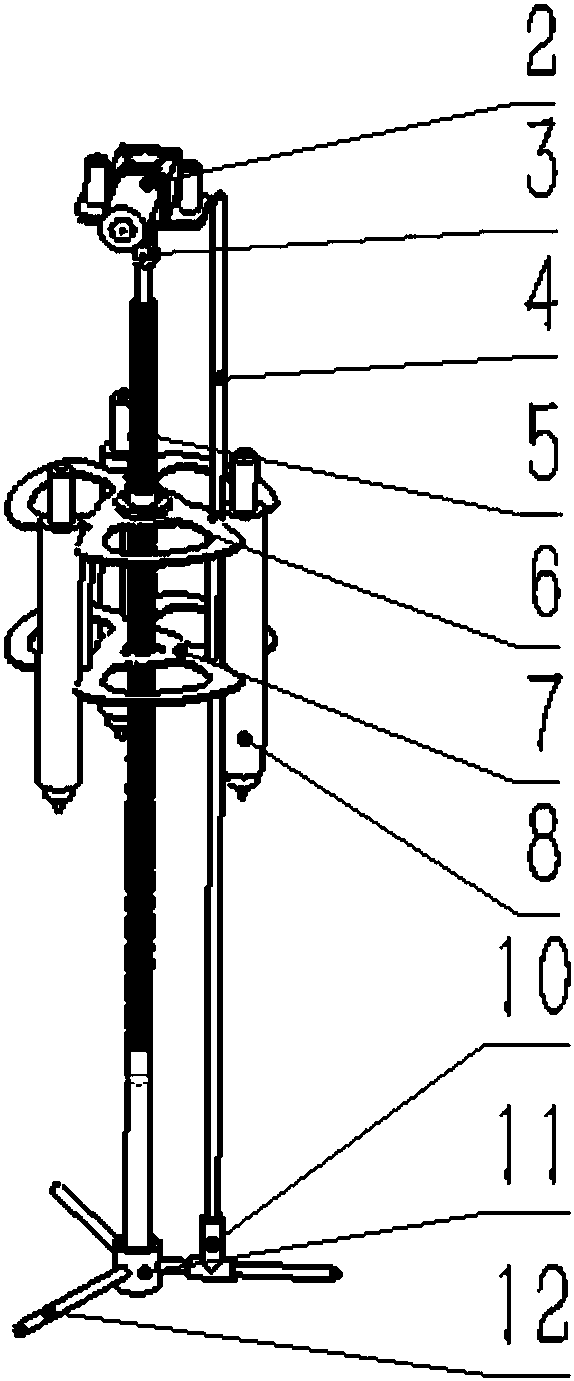

[0029] see Figure 1-3 , a marine buoy monitoring system sensor spiral lifting mechanism, including a prism upper bracket 1, a lifting motor 2, a universal coupling 3, a circular guide rod 4, a lifting screw 5, a threaded flange 6, a sensor bracket 7, three Through pipe 10, screw guide cylinder 11, three-claw bracket 12; the lifting screw 5 passes through the upper bracket 1 of the edge platform, is connected to the lifting motor 2 through a universal coupling 3, is fixed at the center of the bracket beam, and the lower end hangs Placed in the screw guide hole 11 to reduce the amplitude of shaking; the three multi-parameter sensors 8 are locked at an angle of 120° on the sensor bracket 7, and the sensor bracket 7 is connected to the lifting screw 5 through a threaded flange 6; Circular guide rod 4 passes the crossbeam of support 1 on the edge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com