Communicated and connected cremator

A cremation machine and conjoined technology, applied in incinerators, methods of incinerating corpses, indirect carbon dioxide emission reduction, etc., can solve the problems of inability to cremate corpses at the same time, waste of labor, waste of materials, etc., saving manpower, saving materials, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

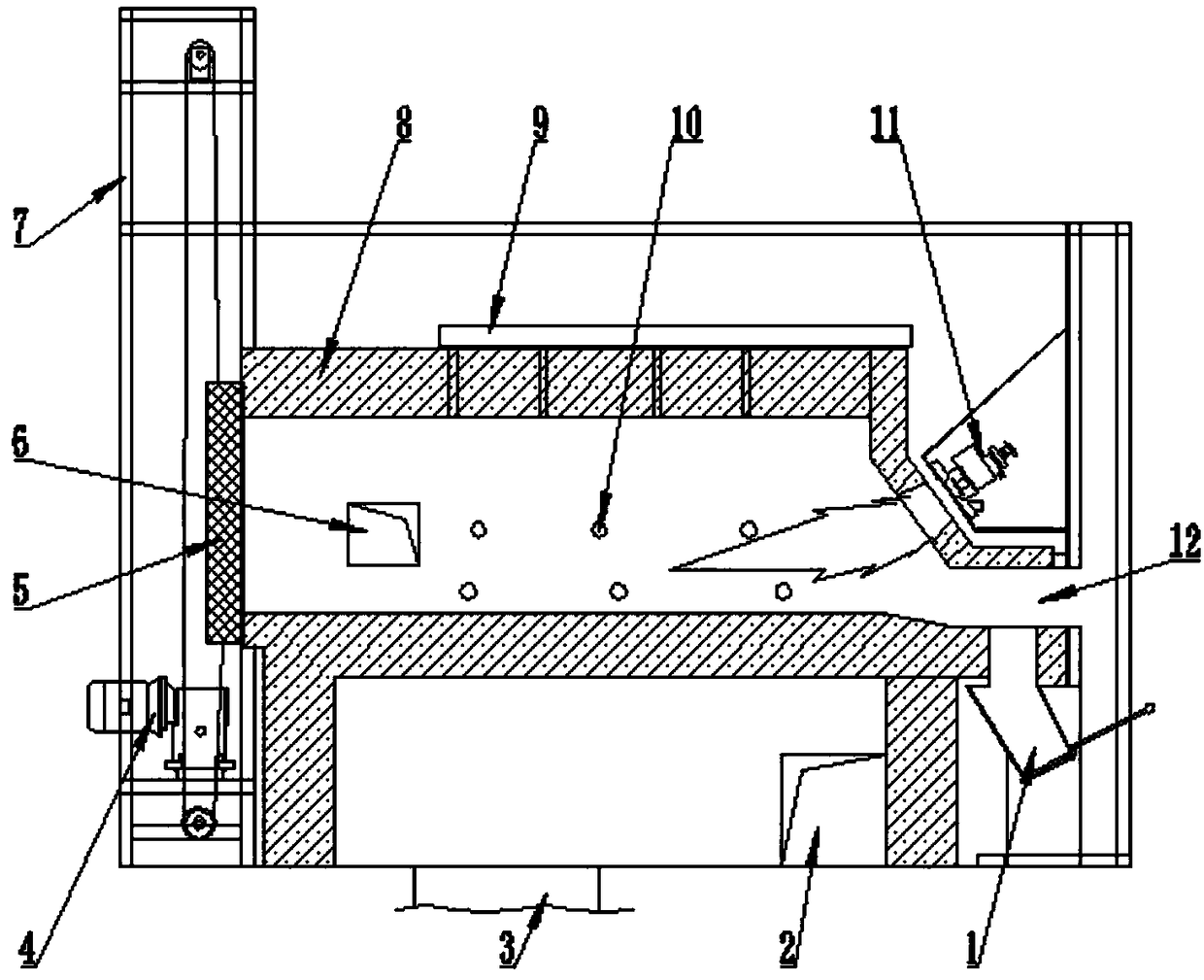

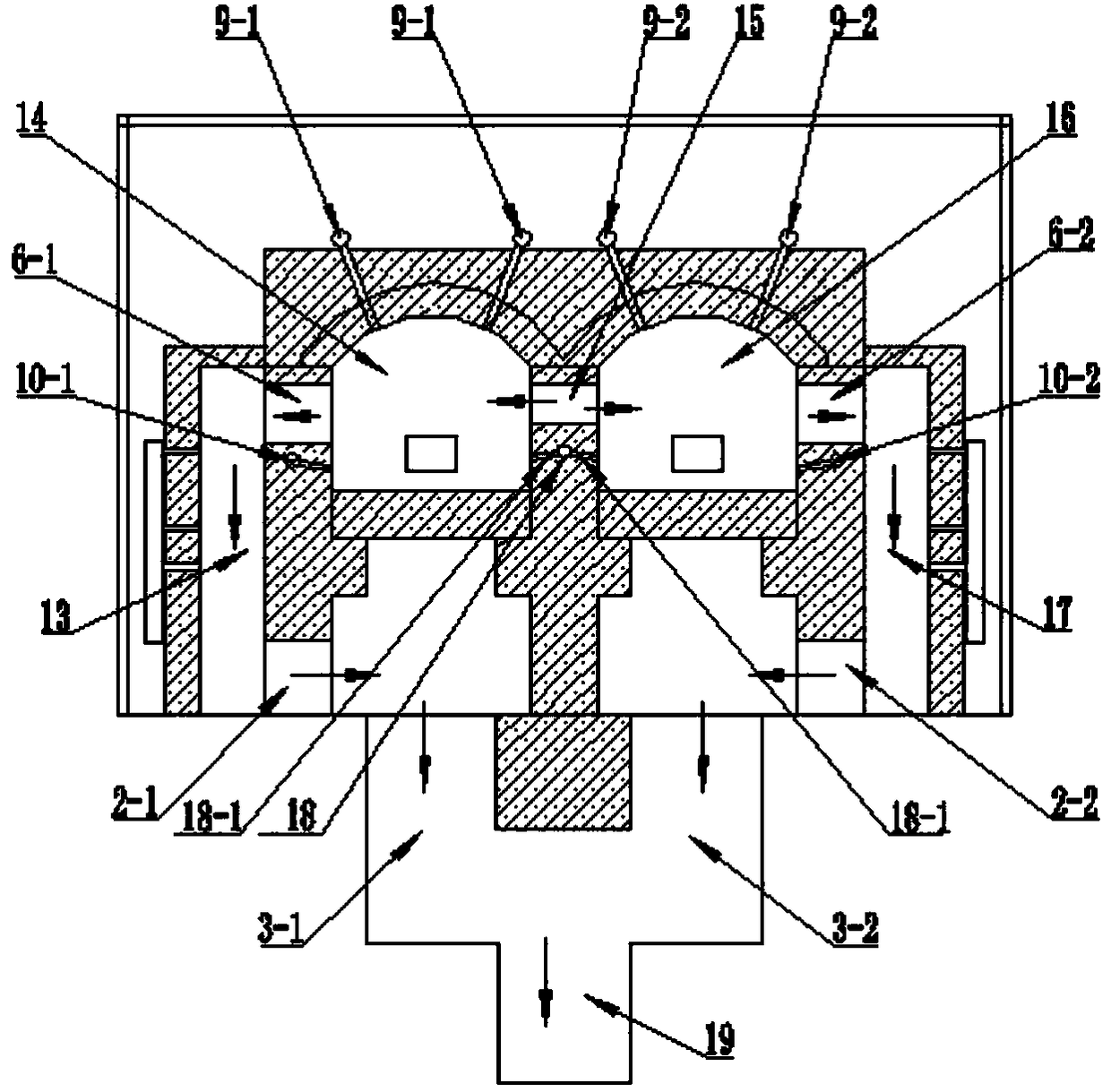

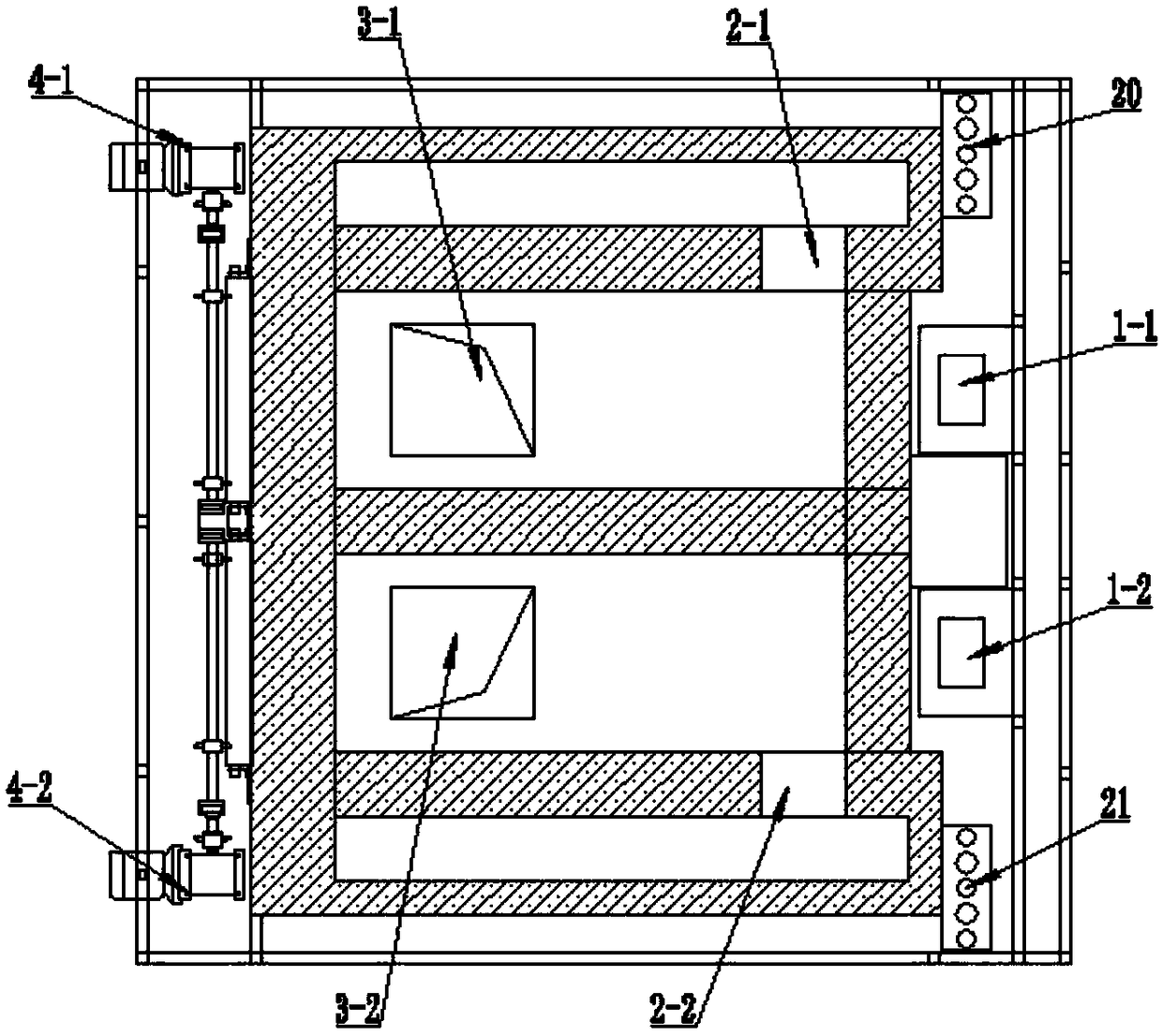

[0026] Example 1, see Figure 1-3 , an intercommunicated cremation machine, comprising a grate body 7, a No. 1 cremator body and a No. 2 cremator body located in the grate body 7; The No. 1 furnace 14, the burner 11 located in the No. 1 furnace 14, the No. 1 smoke return system and the No. 1 oxygen supply air system connected with the No. 1 furnace 14, the No. 1 oxygen supply air system is composed of the No. 1 furnace The bellows 20 supply oxygen; No. 2 cremation mechanism comprises furnace body 8, is positioned at No. 2 furnace 16 in furnace body 8, is positioned at No. 2 burner 11 in No. 2 furnace 16, No. 2 return smoke system that is communicated with No. 2 furnace 16 and The No. 2 oxygen supply wind path system, the No. 2 oxygen supply wind path system is supplied with oxygen by the No. 2 furnace wind box 21; the No. 1 furnace hearth 14 and the No. 2 furnace hearth 16 are connected through the communication port 15; The bellows 21 are jointly connected to a set of oxygen...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap