Waste gas wet dust removal garbage incineration device

A technology of wet dust removal and garbage incineration, which is applied in combined devices, incinerators, combustion methods, etc., can solve the problems of absorption treatment and impact on the environmental protection of incineration equipment, so as to improve environmental protection, facilitate popularization and utilization, and improve the effect of absorption treatment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

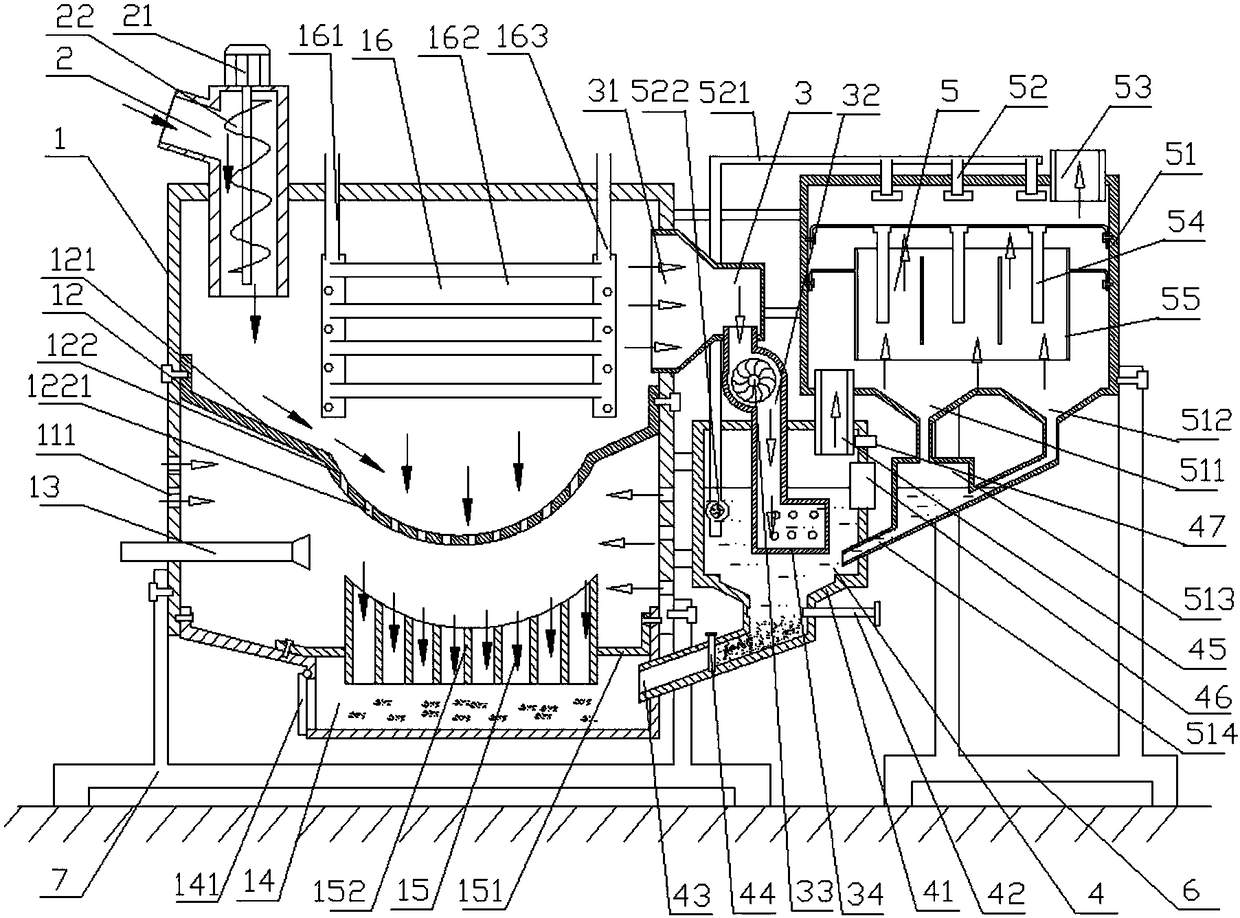

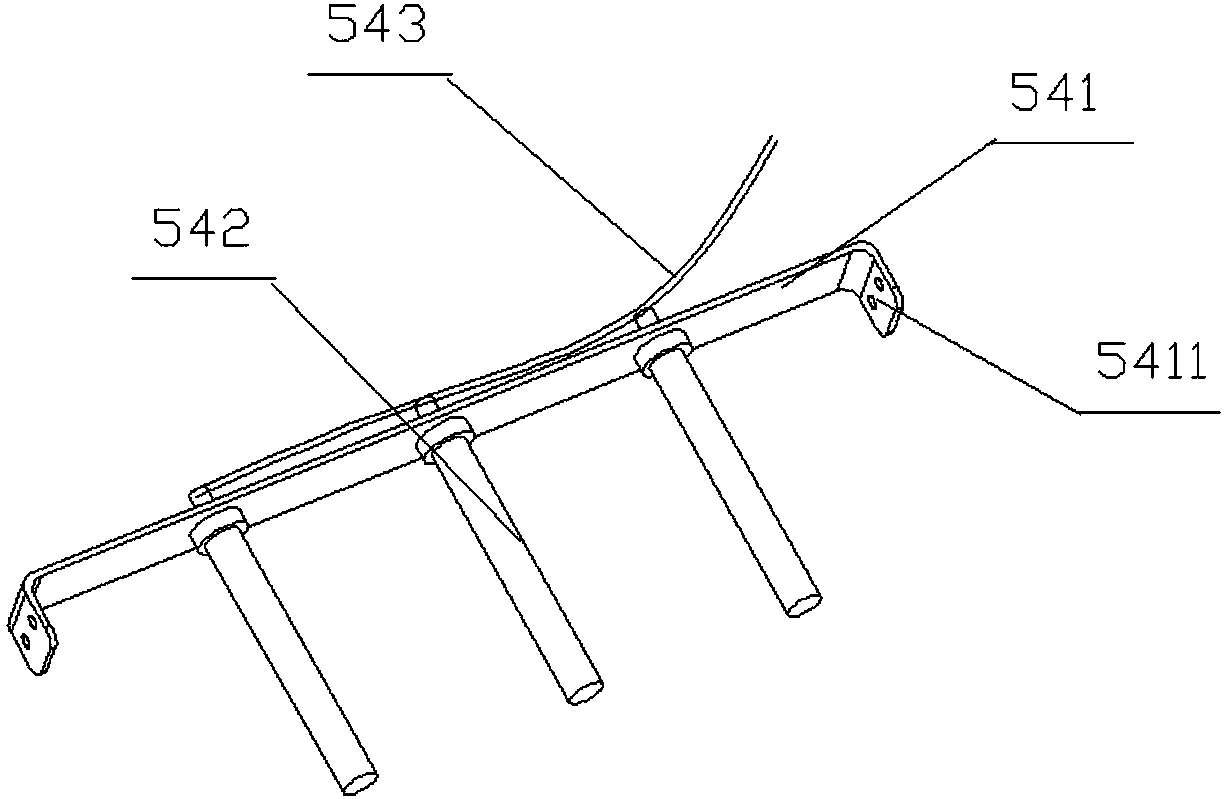

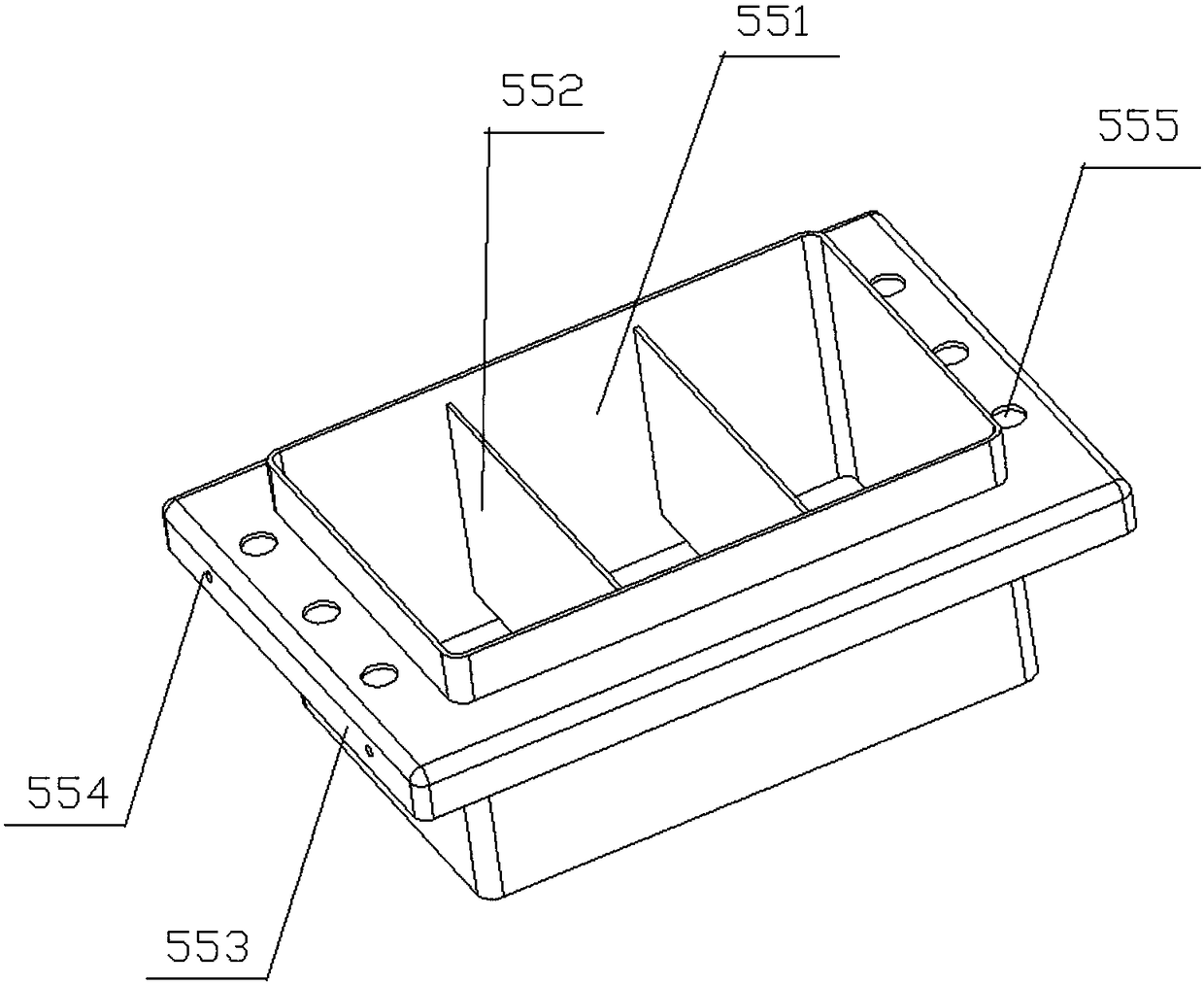

[0020] refer to Figure 1-3 , a waste incineration device for waste gas wet dust removal, comprising a first support frame 7, the upper end of the first support frame 7 is fixedly connected with a combustion box 1, and a combustion grid 12 is arranged in the combustion box 1, and the combustion grid 12 includes a The sliding material inclined plate 121 on the combustion box 1 inwall, the side wall of the sliding material inclined plate 121 is fixedly connected with the inwall of the combustion box 1, the upper end of the sliding material inclined plate 121 is provided with a combustion circular pit 122, and the bottom of the combustion circular pit 122 is provided wit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap