Electric heating radiator

An electric heater and heat sink technology, applied in the field of heating, can solve the problems of water leakage at pipe joints, short service life, troublesome maintenance, etc., and achieve the effects of good sealing performance, easy maintenance, and convenient installation and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

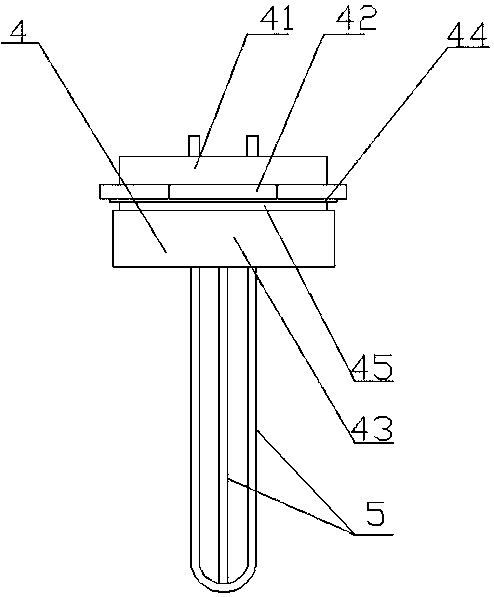

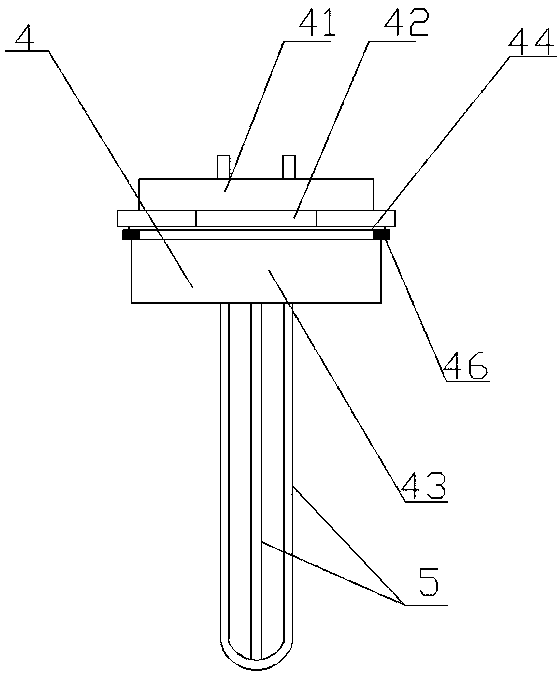

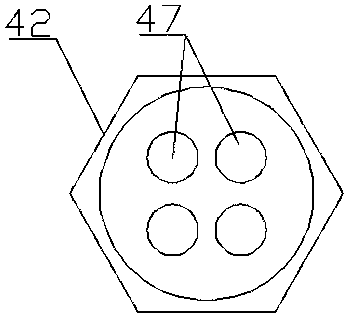

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 The electric radiator shown includes a heat conduction module, an upper oil chamber 2, a lower oil chamber 9, and a heat sink 1 for connecting the upper oil chamber 2 and the lower oil chamber 9. The heat sink 1 is a steel-aluminum composite heat sink or a copper-aluminum heat sink. Composite heat sink, the heat sink 1 of the present invention adopts copper-aluminum composite heat sink, and the copper-aluminum composite heat sink has the advantages of fast heating and good heating effect. The top of one end of the upper oil chamber 2 is provided with a heat transfer oil inlet and outlet, and a vacuum sealing valve 3 is provided at the heat transfer oil inlet and outlet, and the heat transfer oil inlet and outlet are sealed by the vacuum sealing valve 3. The sealing performance is good, ensuring that the heat transfer oil circulates and dissipates heat under vacuum conditions, and, Heat conduction oil is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com