A snap-in structure for identification of cables or optical cables

An optical cable and cable technology, which is applied in the field of snap-in structure for cable or optical cable identification, can solve the problems of reduced bonding force between the identification strip and the sheath layer, increased investment in machinery and equipment, trouble for manufacturers, etc. Strong repairability, high manufacturing efficiency, and the effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

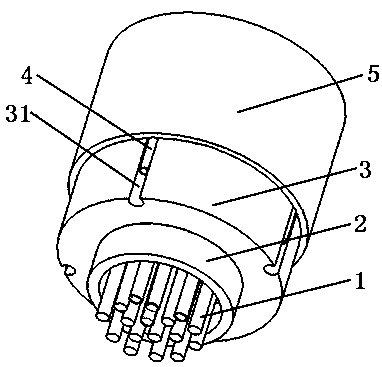

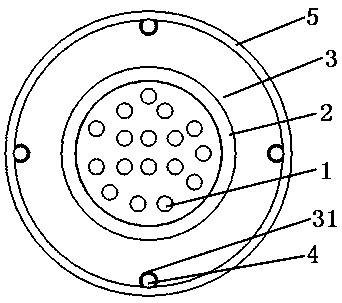

[0045] please see figure 1 with figure 2 , a cable or optical cable that is easily identifiable under bright light and dark light conditions, including a cable or optical cable core 1, a protective layer covering the cable or optical cable core 2, and an extrusion coating outside the protective layer The sheath layer 3 has at least one sheath groove 31 on the outer edge of the sheath layer, and is characterized in that there is a night vision unit 4 in the sheath groove, and the sheath layer and the night vision unit are covered with a The transparent light-transmitting strip 5; the night vision unit is a linear or rope-like structure that absorbs visible light and emits visible light.

[0046] The above-mentioned cable or optical cable that is easy to identify under bright light and dark light conditions, wherein the sheath grooves are one or two or three or four or other multiple, and can be symmetrical or non-symmetrical when there are multiple grooves. Symmetrically dis...

Embodiment 2

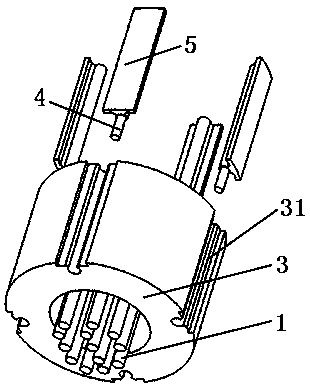

[0052] please see Figure 3 to Figure 5 , a cable or optical cable that is easily identifiable under bright light and dark light conditions, comprising a cable or optical cable core 1, a sheath layer 3 covering the cable or optical cable core, and the outer edge of the sheath layer has at least one The sheath groove 31 is characterized in that: the light-transmitting strip 5 is embedded in the sheath groove; the sheath groove is composed of the first part 311 of the sheath groove, the second part 312 of the sheath groove, the The third part 313 and the fourth part 314 of the sheath groove are formed, one end of the third part of the sheath groove is connected with the first part of the sheath groove and the second part of the sheath groove, and the third part of the sheath groove The other end is connected to the fourth part of the sheath groove, the first part of the sheath groove is connected to the second part of the sheath groove, and the outer edges of the first part of t...

Embodiment 3

[0064] please see Image 6 with Figure 7 , and refer to Figure 3 to Figure 5 , a kind of cable or optical cable that is easy to identify under bright light and dark light conditions, basically the same as the implementation example 2, the difference is that: the fourth part 54 of the light-transmitting strip has an open groove 56 communicating with the night vision hole 55, this In this way, the night vision unit can be inserted into the night vision hole 55 through the opening groove 56, which not only saves the material of the fourth part 54 of the light-transmitting strip, but also makes it more convenient to manufacture.

[0065] In the present invention, the night vision unit is very easy to replace, but in the prior art, the extruded one cannot be replaced, and the related materials can only be re-extruded after being stripped off. Therefore, the present invention is more convenient and flexible to replace.

[0066] In Embodiments 2 and 3 of the present invention, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com