3cm I-shaped waveguide gradient line impedance converter

An impedance converter and I-shaped technology, applied in the electrical field, can solve the problems of high-power waveguide ignition, narrow working frequency band of magnetron energy output device, etc., to eliminate waveguide ignition, eliminate hidden dangers of right-angle tip discharge, prevent The effect of high frequency breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with specific accompanying drawing, the present invention is further explained and illustrated;

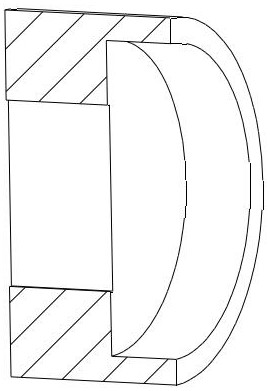

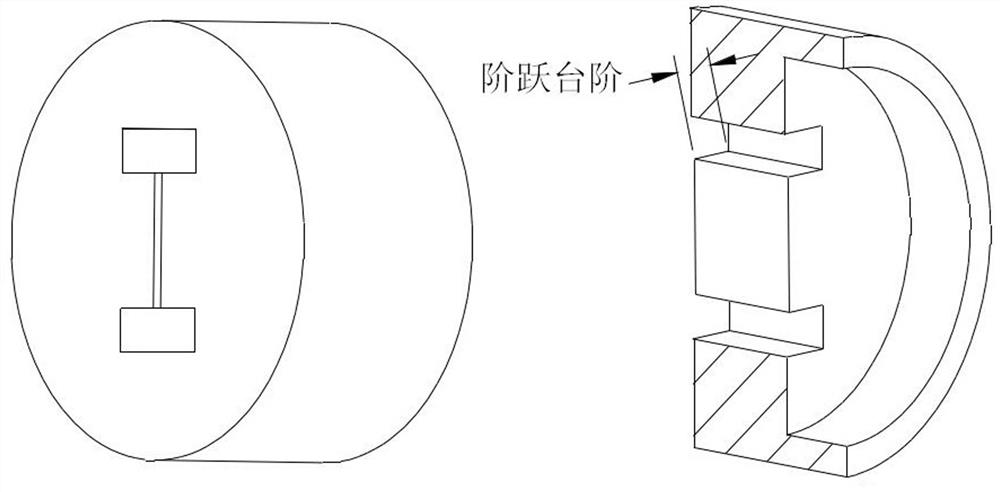

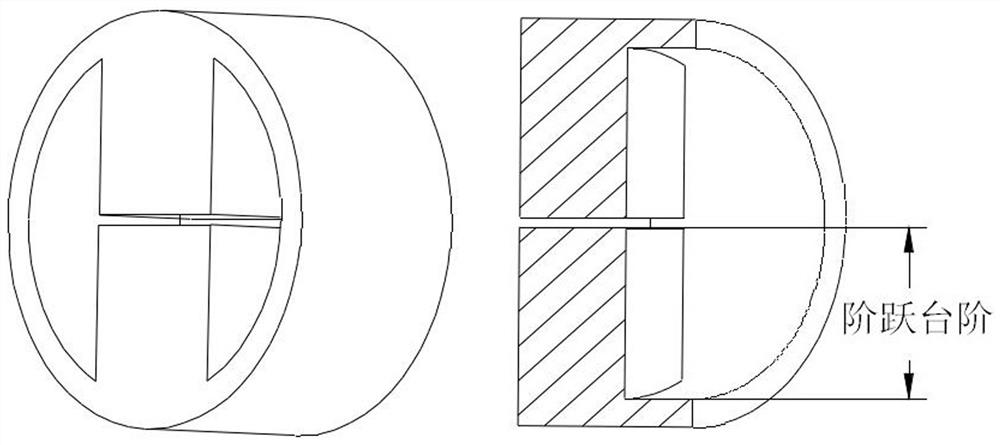

[0028] A 3CM I-shaped waveguide gradient line impedance converter, including a circular transition waveguide 1, the output end of the circular transition waveguide is connected with a load circular waveguide 3, and a ring groove is formed between the output end of the circular transition waveguide and the inner wall of the load circular waveguide Steps, a pair of ridges 2 are fixed in the circular transition waveguide, and the two ridges are symmetrically arranged in an I-shape in the circular transition waveguide cavity, and the outer ridges of the two ridges 2 are adapted to the inner wall of the circular transition waveguide 1, The inner ridge faces of the two ridges 2 are curved surfaces transitioning along the exponential gradient line, the two ridges 2 transition to the middle of the loaded circular waveguide along the input end of the circular tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com