Abrasives

A technology of abrasive layer and abrasive grains, which is applied in the direction of abrasives, polishing compositions containing abrasives, and other chemical processes, which can solve the problems of reduced grinding efficiency and achieve excellent grinding rate and the effect that the grinding rate is not easy to decrease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

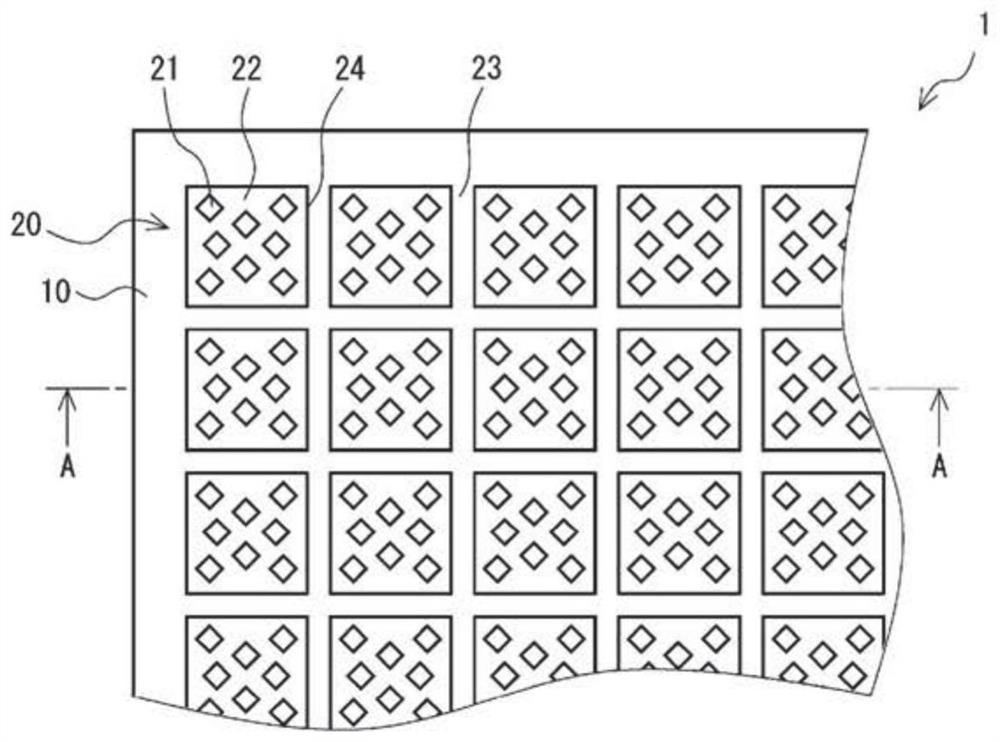

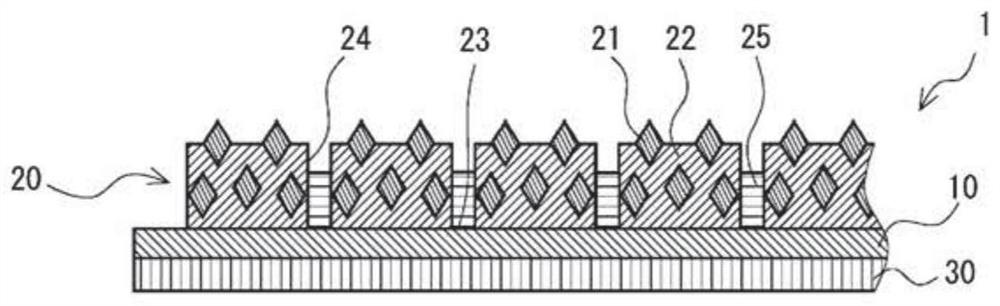

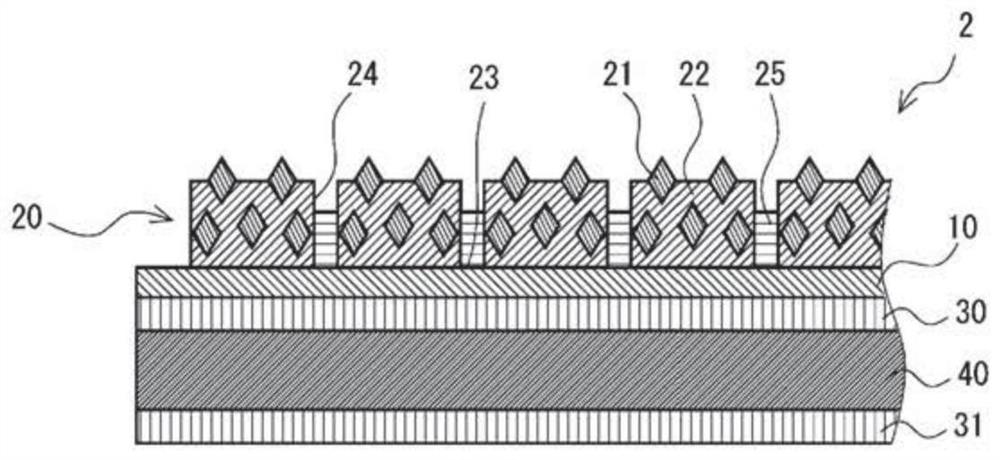

[0093] The present invention is not limited to the above-described embodiments, and can be implemented as various changes and improvements other than the above-described aspects. In the above-described embodiment, the grooves are formed in a grid with equal intervals, but the intervals of the grids may not be equal intervals, for example, the intervals may be changed in the vertical and horizontal directions. However, when the intervals of the grooves are different, there is a possibility that anisotropy will be generated in polishing, so the intervals are preferably equal.

[0094] In addition, the planar shape of the grooves does not need to be a grid shape, for example, a shape in which polygons other than quadrilaterals are repeated, a circular shape, a shape with a plurality of parallel lines, etc., or may be concentric circles. In addition, the planar shape of the grooves may be stripes arranged in only one direction.

[0095] In the above-mentioned embodiment, a method...

Embodiment 1

[0104] Diamond abrasive grains were prepared, and the average particle diameter was measured using "Microtrac MT3300EXII" manufactured by Nikkiso Co., Ltd. The average particle size of the diamond abrasive grains is 44 μm. Furthermore, the type of the diamond abrasive grains is treated diamond obtained by coating 55 mass% (mass percent) nickel on single crystal diamond.

[0105] Silicate (No. 3 sodium silicate), the diamond abrasive grains and alumina (Al 2 o 3 , average particle diameter is 12 μm) mix, become 30vol% and the mode adjustment that the content of filler relative to abrasive layer becomes 40vol% with the content of diamond abrasive grain relative to abrasive layer, obtain the coating liquid of composition for abrasive layer.

[0106] In addition, silicate (No. 3 sodium silicate), and alumina (Al 2 o 3 , with an average particle diameter of 12 μm) were mixed and adjusted so that the content of the filler relative to the filled portion became 70 vol%, to obtain ...

Embodiment 2~ Embodiment 6

[0112] The area of the convex portion in Example 1 and the area occupancy ratio with respect to the entire polishing layer were changed as shown in Table 1 to obtain abrasive materials of Examples 2 to 6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com