Polishing pad and method for manufacturing same, and method for manufacturing abrasive

A manufacturing method and a technology of grinding pads, which are applied in the direction of grinding machine tools, manufacturing tools, grinding tools, etc., can solve the problems of difficult operation of metal platforms, labor-intensive maintenance and management, etc., and achieve the effect of excellent surface quality and excellent grinding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

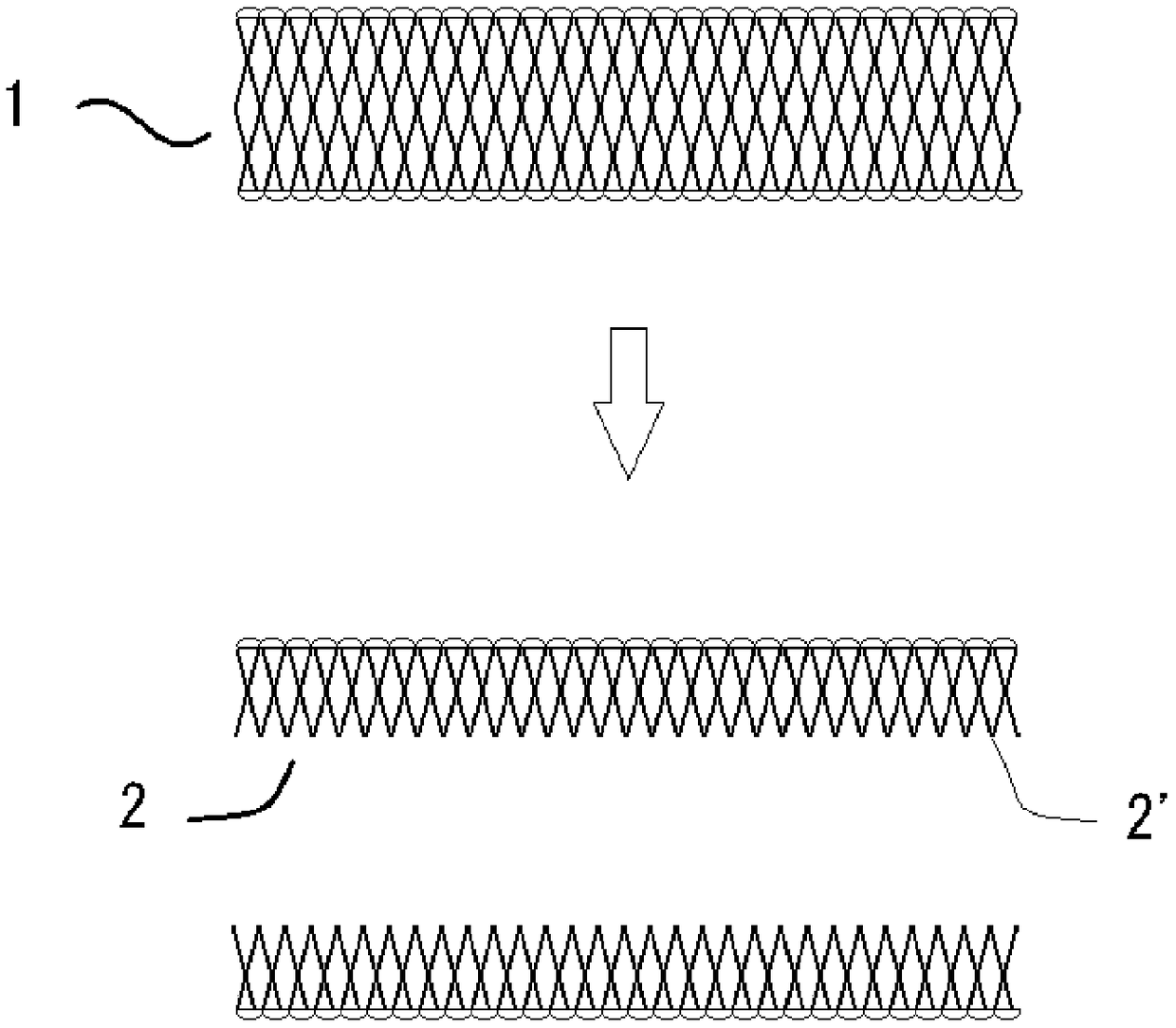

Method used

Image

Examples

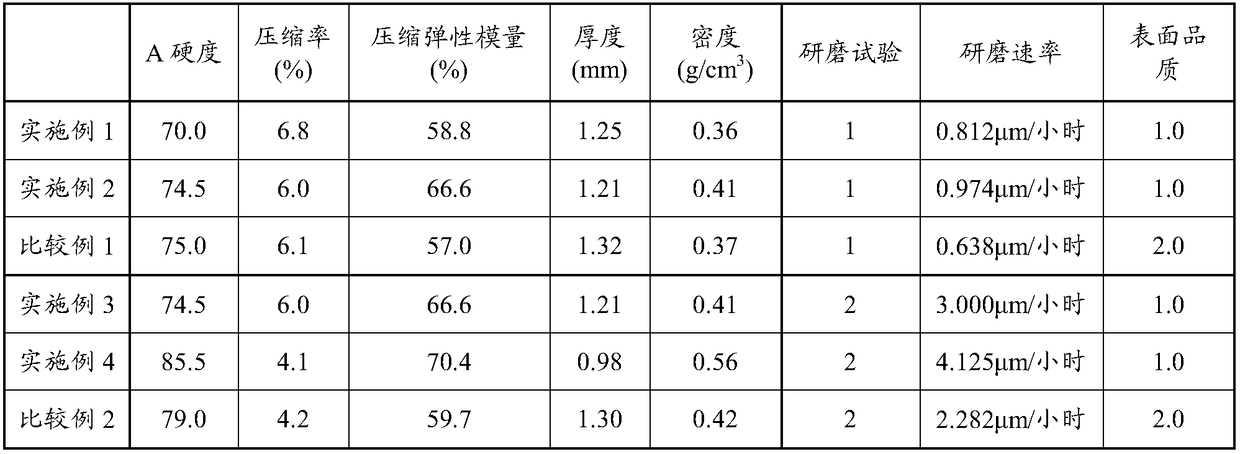

Embodiment 1

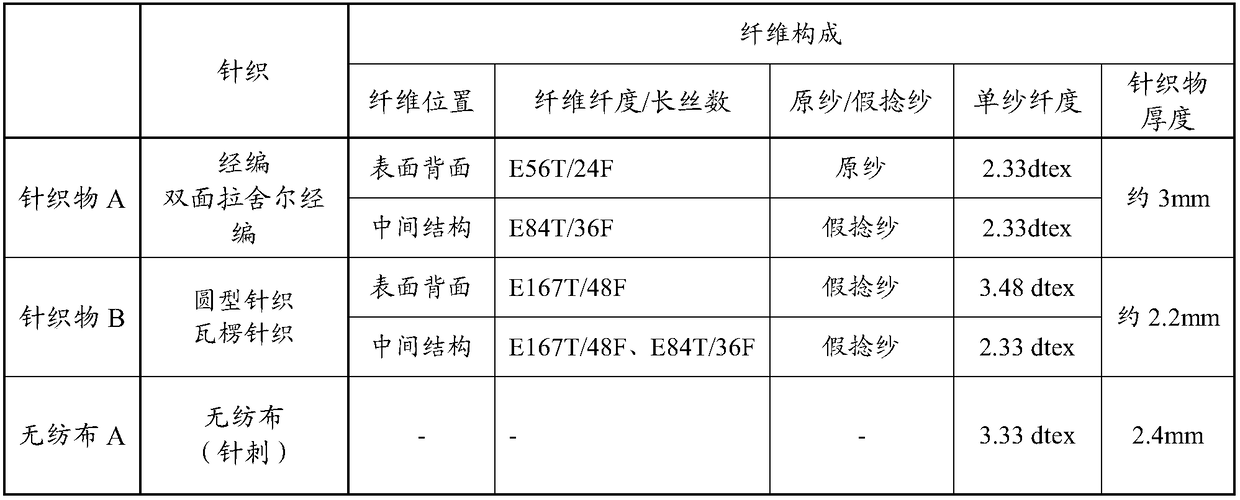

[0213] (one impregnation process)

[0214] 56.7 parts by mass of polycarbonate-based urethane resin (manufactured by DIC Corporation, trade name "CRISVON S705") and 43.3 parts by mass of N,N-dimethylformamide were mixed to prepare a resin solution. The knitted fabric A was dipped in the obtained resin solution, and the excess resin solution was squeezed off with a nip roll, thereby impregnating the knitted fabric A substantially uniformly with the resin solution. Next, the knitted fabric A was immersed in a coagulation solution containing water at 18° C., whereby the primary impregnated resin was coagulated and regenerated to obtain a resin-impregnated knitted fabric. Then, the resin-impregnated knitted fabric was taken out from the coagulation solution and dried to obtain a resin-impregnated knitted fabric from which the surface skin layer was removed by buffing.

[0215] (dipping process)

[0216] Next, the resin-impregnated knitted fabric obtained above was immersed in an...

Embodiment 2

[0222] In addition to adjusting the nip condition of the nip roll so that the density of the polishing pad becomes 0.41 g / cm 3 Except that, the polishing pad of Example 2 was obtained by the method similar to Example 1. The knitted fabric content was 32 mass % with respect to the whole polishing pad.

Embodiment 3

[0226] The polishing pad of Example 3 was obtained in the same manner as in Example 2, except that grooves having a U-shaped cross section with a pitch of 30 mm, a width of 2 mm, and a depth of 0.5 mm were provided on the polishing surface. The knitted fabric content was 32 mass % with respect to the whole polishing pad.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com