Machining line

A technology for processing lines and workpieces, applied in metal processing, etc., can solve problems such as cuts, and achieve the effects of improving efficiency, saving time, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

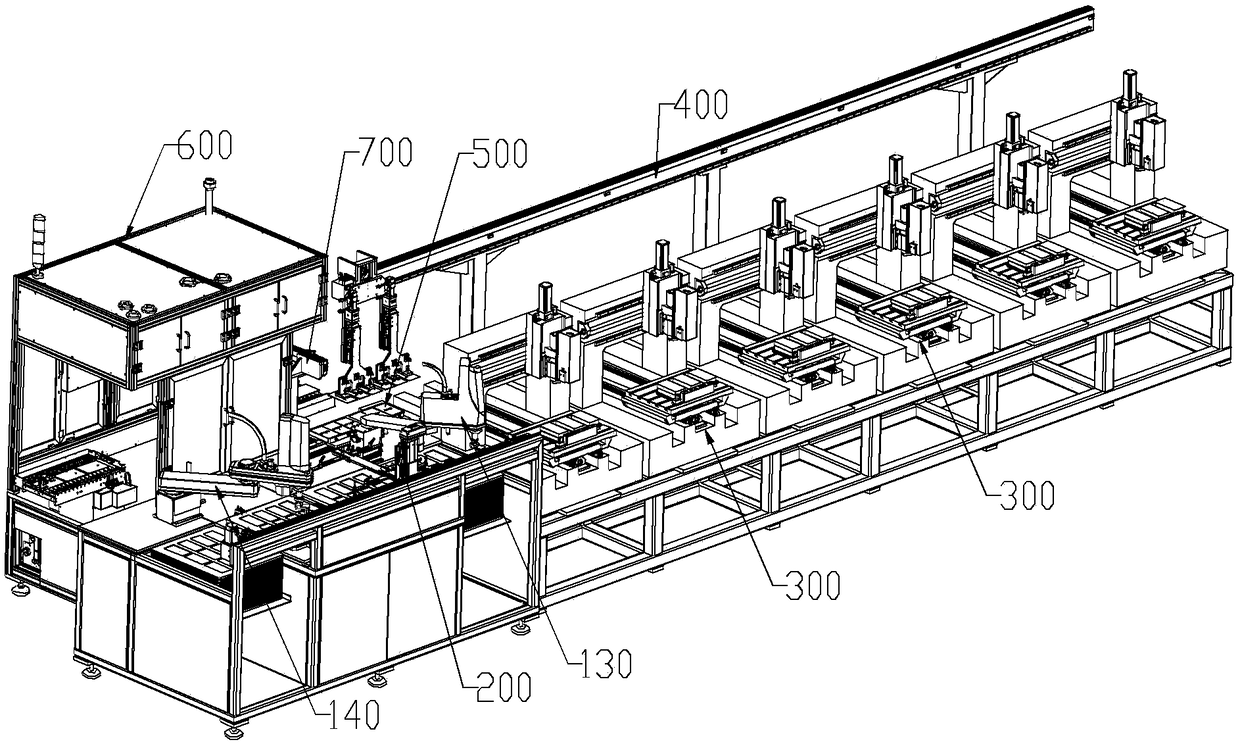

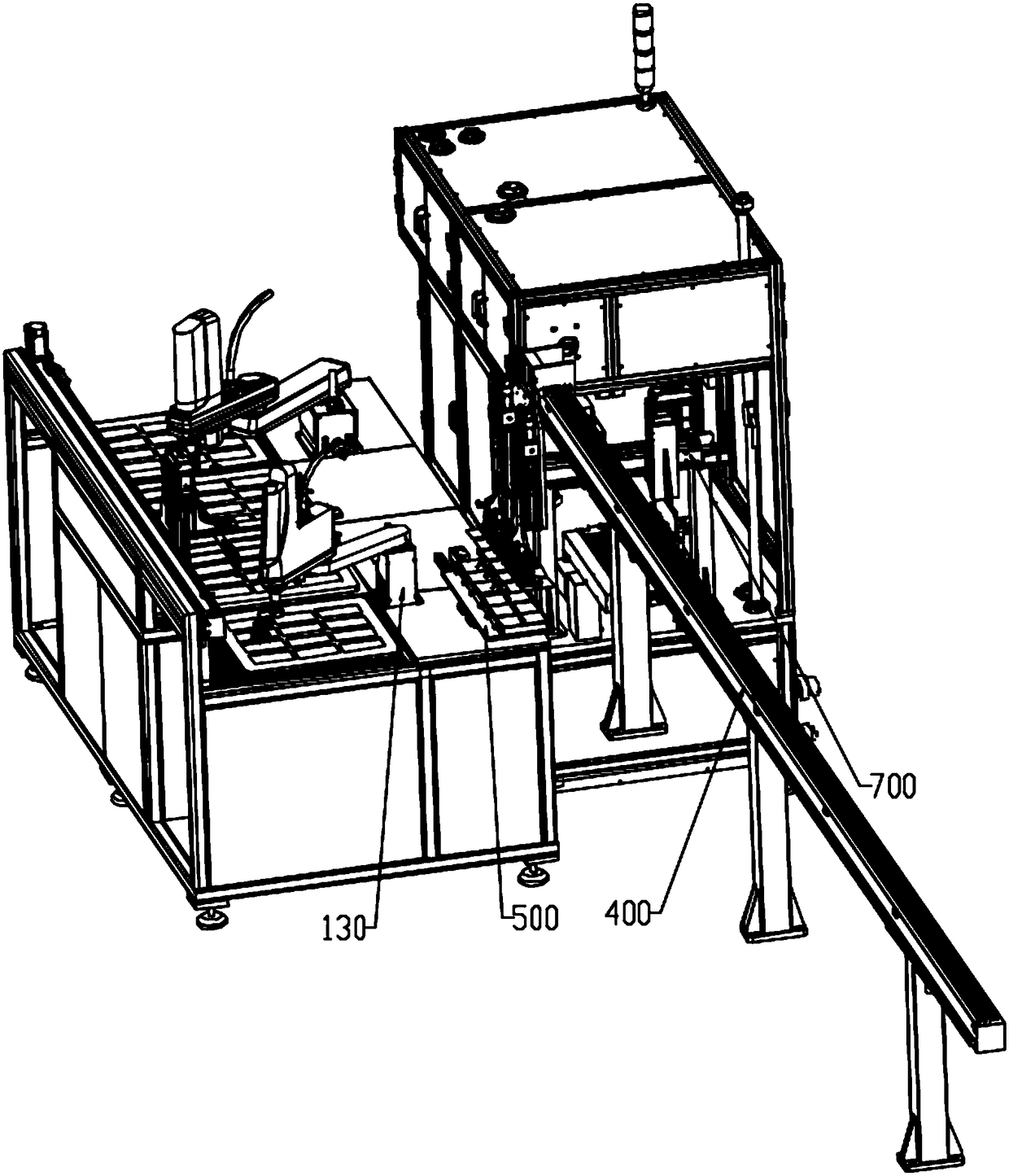

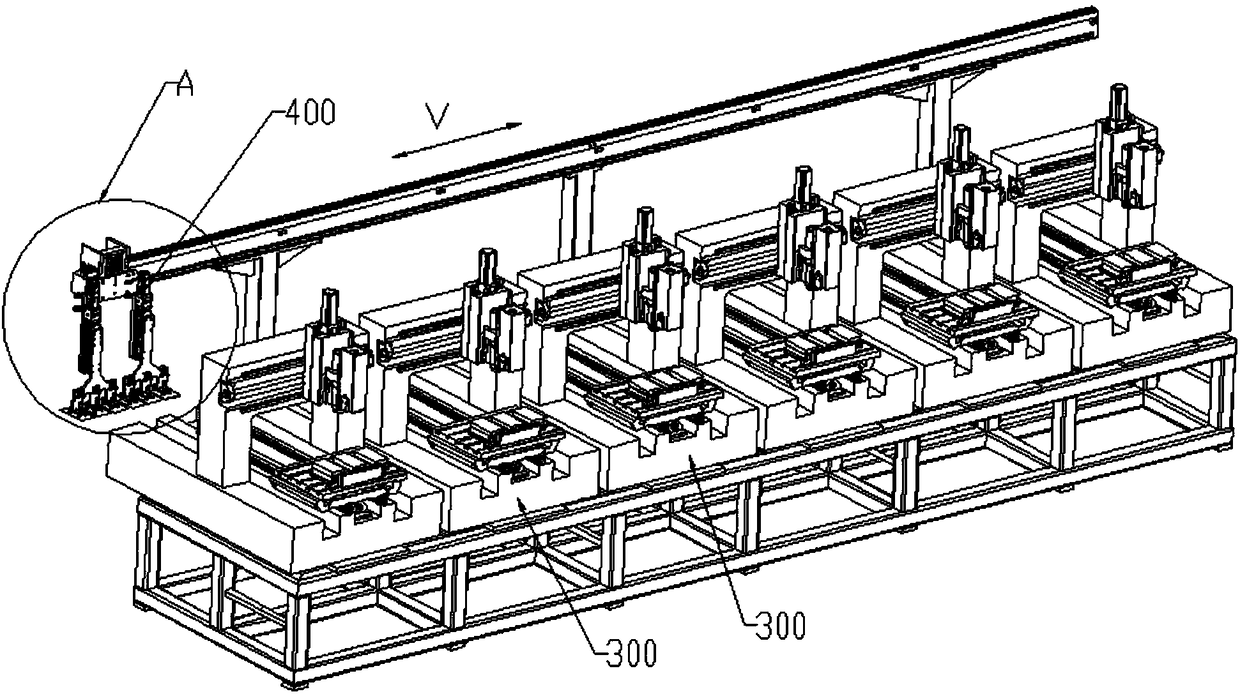

[0030] Such as Figure 1-12 As shown, a processing line includes a loading area 110 for placing a loading tray, a transfer station 500, a feeding manipulator arranged at the loading area 110 and used to transfer workpieces from the loading tray to the transfer station 500 130, the machine tool 300, and the transfer manipulator 400 for transferring the workpiece from the transfer station 500 to the machine tool 300; the transfer manipulator 400 includes a holding mechanism 410 and a first translation drive mechanism for driving the holding mechanism 410 to move horizontally 440; the holding mechanism 410 includes a first lift seat 411, a first lift dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com