Rolling, cutting and lapping device for wood fibers

A lapping device, wood fiber technology, applied in wood processing equipment, bark area/debris/dust/waste removal, manufacturing tools, etc., can solve the problems of workers' health hazards, environmental pollution, etc., and achieve simple structure , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

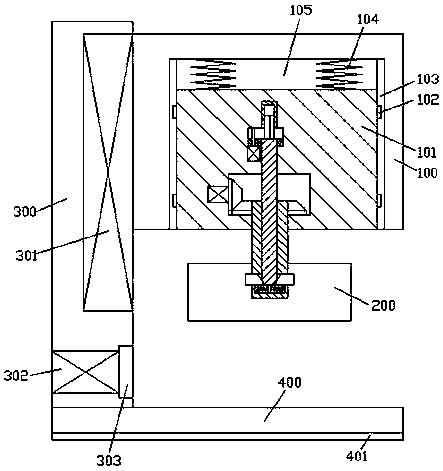

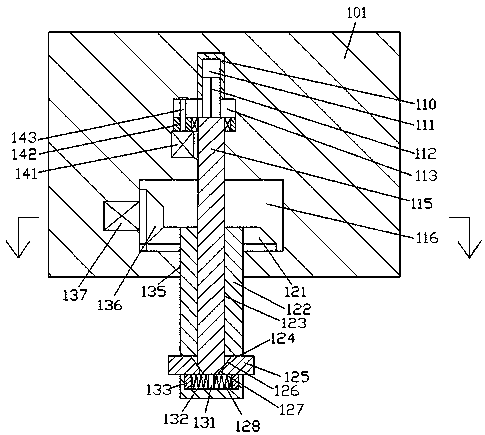

[0014] Combine below Figure 1-4 The present invention will be described in detail.

[0015] refer to Figure 1-4 , according to an embodiment of the present invention, a wood fiber milling and lapping device includes a support frame 300 fixedly installed on the bottom frame 400 and an installation main body 100 installed on the right end surface of the support frame 300 through a landing gear 301 The bottom end surface of the bottom frame 400 is fitted with a shockproof pad 401, and the bottom end surface of the installation main body 100 is provided with a slowing cavity 105, and a rolling body 101 is installed in the slowing cavity 105 for sliding fit. The top of the cutting main body 100 is symmetrically fixed with an elastic member 104, the top of the elastic member 104 is fixedly connected with the inner bottom wall of the slowing chamber 105, and the inner wall of the milling main body 101 is provided with a transfer chamber 116, and the transfer chamber 116 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com