Refrigerating door foaming mold with good positioning accuracy and good demolding convenience

A foaming mold and demoulding technology, which is applied in the field of refrigeration door foaming molds, can solve the problems that the upper mold and the lower mold cannot be aligned, the positioning accuracy of the foaming mold is reduced, and the mold opening speed is slow, so as to avoid scratches on the refrigeration door , Reduce mold cost and reduce gas resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

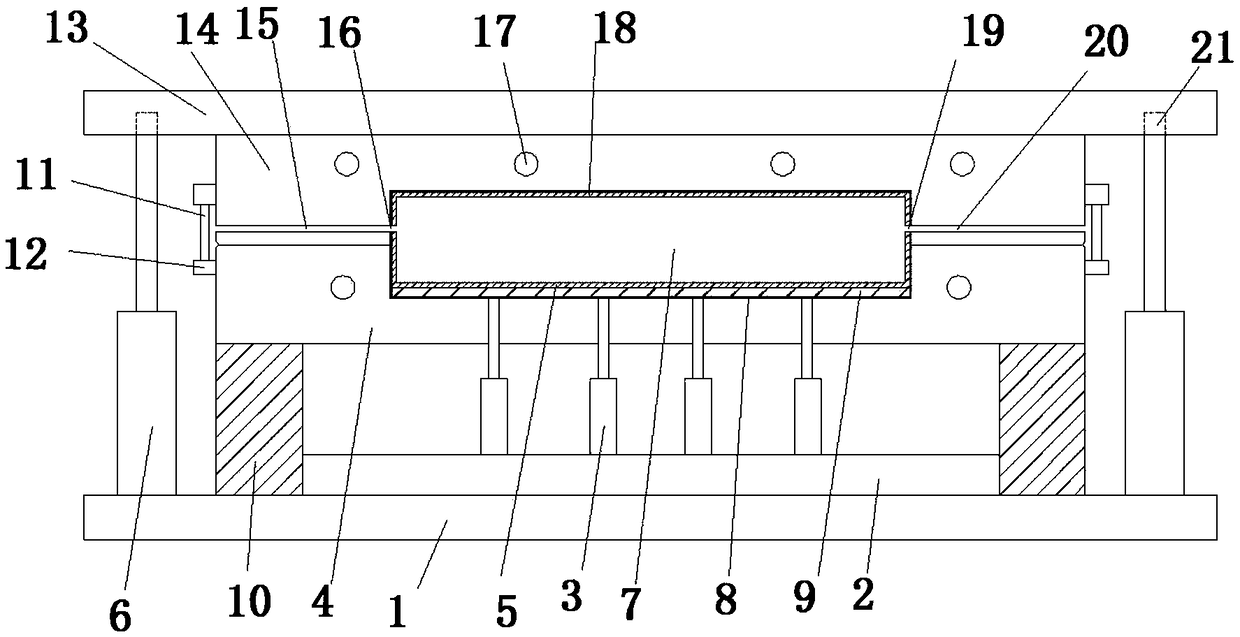

[0019] Referring to the accompanying drawings, a refrigerated door foam mold with precise positioning and easy demoulding includes a base 1, a hydraulic cylinder base 2 is provided on the upper end surface of the base 1, and a lower mold is provided above the hydraulic cylinder base 2 4. An upper mold 14 is arranged above the lower mold 4, and the upper mold 14 and the lower mold 4 enclose a foaming cavity 7, and an upper mold mounting plate 13 is arranged on the upper end surface of the upper mold 14. The four corners of the lower end surface of the upper die mounting plate 13 are respectively provided with a circular groove 21, and each of the four corners on the upper end surface of the base 1 is provided with a first hydraulic cylinder that is matched with the circular groove 21 6. There are a plurality of second hydraulic cylinders 3 on the upper end surface of the hydraulic cylinder base 2, and the output ends of the second hydraulic cylinders 3 are all against the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com