Carbon fiber composite material skylight reinforcing plate production method

A technology of composite materials and production methods, which is applied to other household appliances, household appliances, household components, etc., can solve the problem that the sunroof reinforcement plate cannot meet the lightweight requirements of automobiles, and achieve obvious lightweight effects, good application prospects, and structural performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

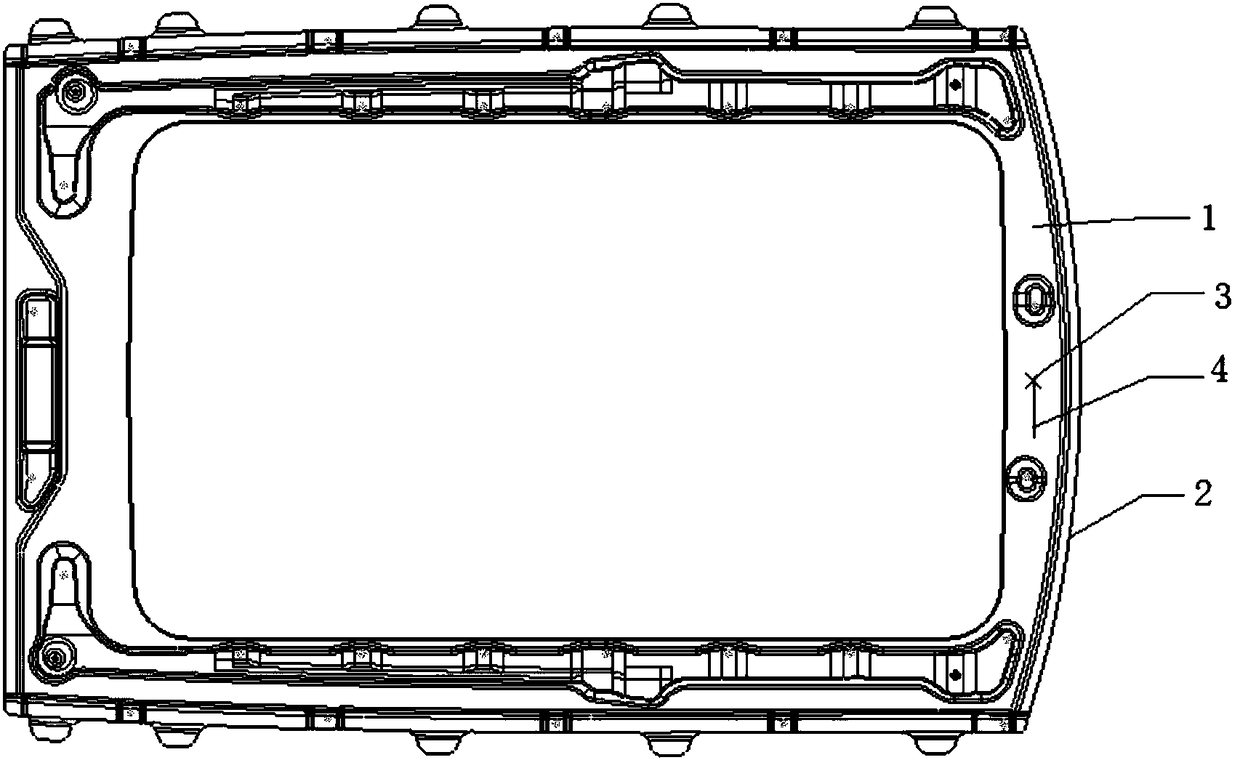

[0024] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

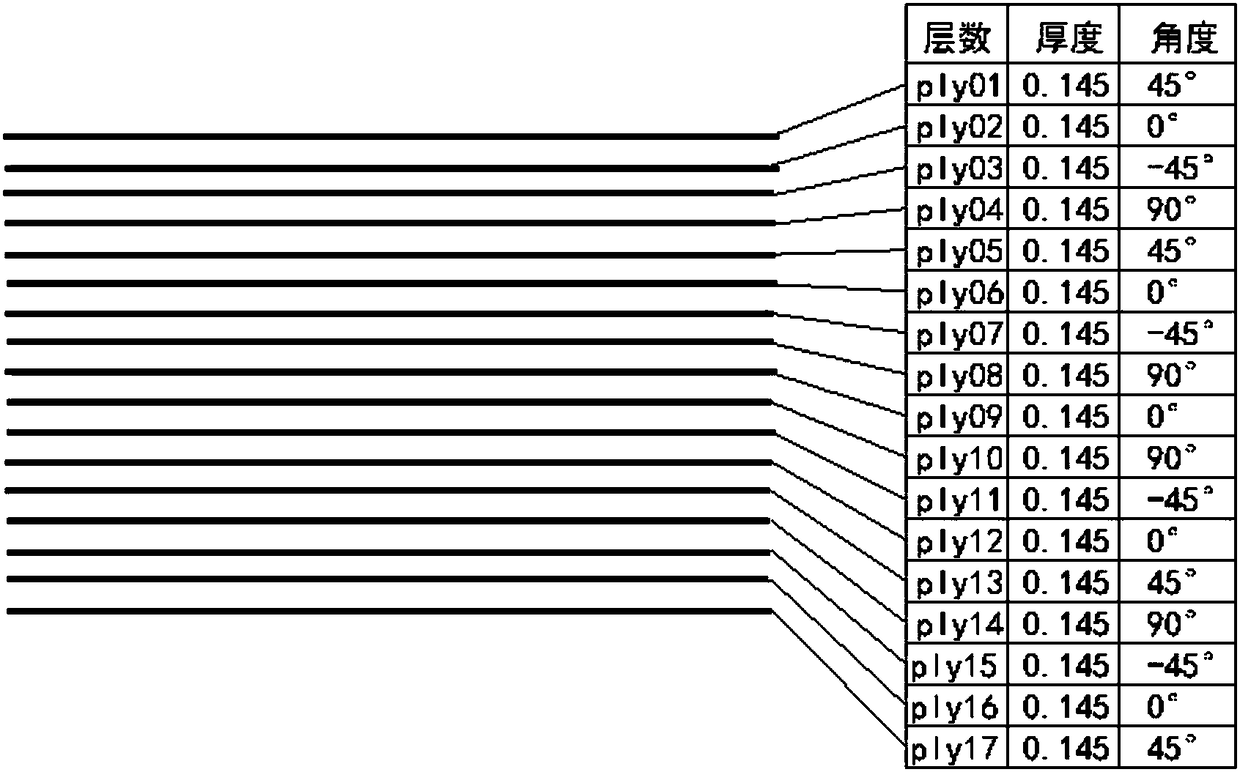

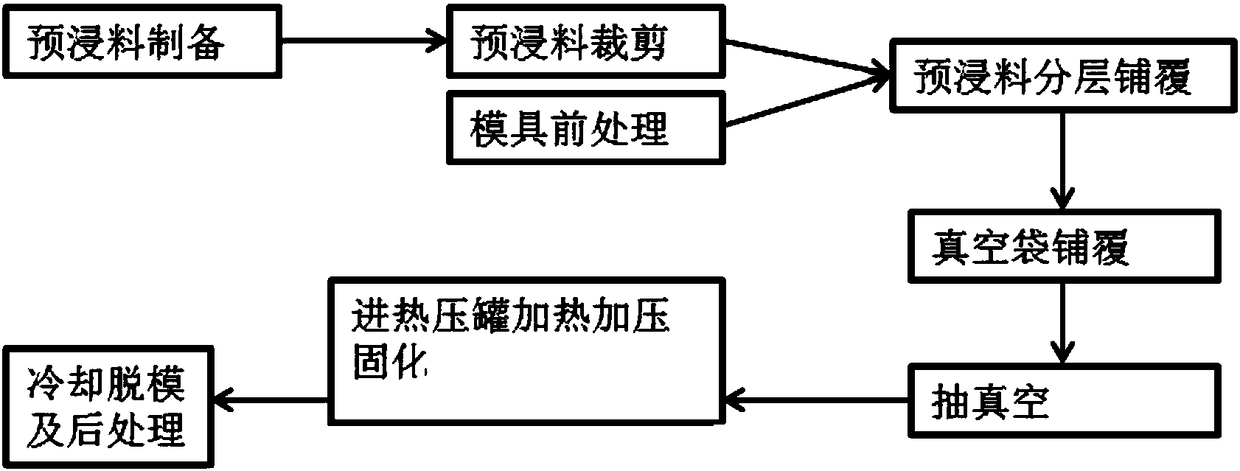

[0025] This carbon fiber composite skylight reinforcing plate production method of the present invention, as image 3 As shown, the following steps are included: preparing carbon fiber composite material prepreg; cutting the prepreg into an overall pavement shape; mold pretreatment; laying the cut prepreg layer by layer on the molding surface of the mold; After the prepreg is laid, the outer side is covered with a vacuum bag and vacuumized; after the laying, the whole is sent into an autoclave to be heated and pressurized for curing; cooling and demoulding treatment. The material is made of carbon fiber prepreg layered at different angles, and the structure is formed by the autoclave process. The production process uses automatic blanking machine to cut the cloth and lay the layers manually. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com