Hardening and tempering method for 12Cr13 stainless steel bar

A stainless steel bar, quenching and tempering technology, applied in the furnace type, furnace, heat treatment furnace and other directions, can solve the problems of high instantaneous heating energy consumption, high production cost, low production efficiency, etc. The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] 1. Steel ingot smelting process

[0056] The chemical composition of the electroslag ingot is shown in Table 3.

[0057] 2. Steel ingot rolling process

[0058] The rolled product size is ф30mm bar.

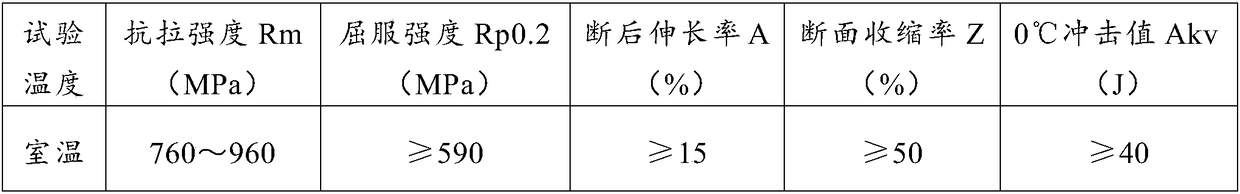

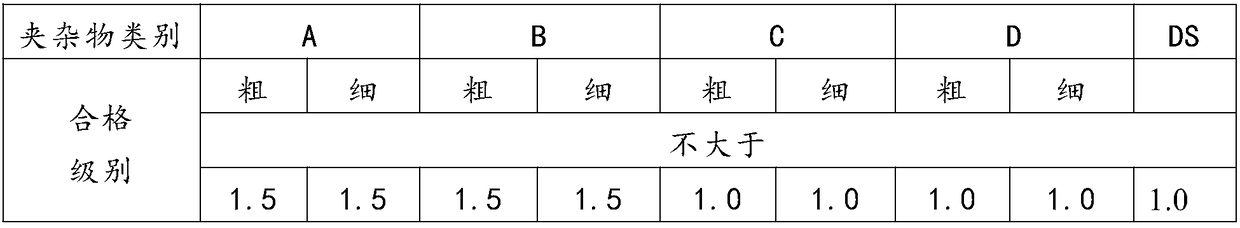

[0059] 3. Incomplete pre-annealing + quenching + tempering heat treatment for finished bars

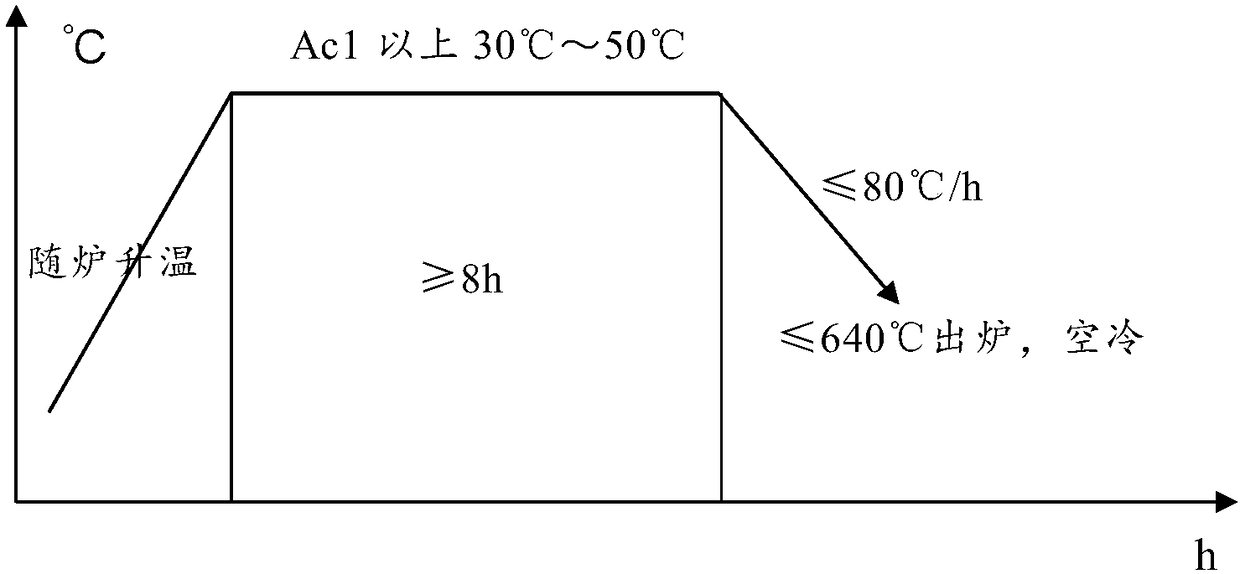

[0060] The first step: the finished bar is incompletely annealed in a 9# chamber furnace, the annealing temperature is 760°C, the holding temperature deviation is ±10°C, and the heat preservation is for 16h, and then slowly cooled to 620°C to 628°C at a speed of no more than 50°C / h ℃ out of the oven, air-cooled.

[0061] Step 2: The bar after incomplete pre-annealing is quenched and heat-treated in a continuous furnace, the quenching temperature is 930°C, the holding temperature deviation is ±10°C, and the holding time is 1h40min;

[0062] The third step: the quenching of the bar is cooled by water-air alternate time control method, the surface temperature of the bar is not hi...

Embodiment 2

[0071] 1. Steel ingot smelting process

[0072] The chemical composition of the electroslag ingot is shown in Table 3.

[0073] 2. Steel ingot rolling process

[0074] Rolled product size ф50mm bar.

[0075] 3. Incomplete pre-annealing + quenching + tempering heat treatment for finished bars

[0076] Step 1: The finished bar is incompletely annealed in a 7# chamber furnace, the annealing temperature is 760°C, the holding temperature deviation is ±10°C, and the holding time is 18h, and then slowly cooled to 630°C at a speed of no more than 60°C / h and released from the furnace. air cooled.

[0077] Step 2: The bar after incomplete pre-annealing is quenched and heat-treated in a continuous furnace, the quenching temperature is 930°C, the holding temperature deviation is ±10°C, and the holding time is 2.5h;

[0078] The third step: the quenching of the bar is cooled by water-air alternating time control method, the surface temperature of the bar is not higher than 280 ℃, and a...

Embodiment 3

[0087] 1. Steel ingot smelting process

[0088] The chemical composition of the electroslag ingot is shown in Table 3.

[0089] 2. Steel ingot rolling process

[0090] Rolled product size ф75mm bar.

[0091] 3. Incomplete pre-annealing + quenching + tempering heat treatment for finished bars

[0092] Step 1: The finished bar is incompletely annealed in a 7# chamber furnace, the annealing temperature is 760°C, the holding temperature deviation is ±10°C, and the holding time is 18h, and then slowly cooled to 630°C at a speed of no more than 60°C / h and released from the furnace. air cooled.

[0093] Step 2: The bar after incomplete pre-annealing is quenched and heat-treated in a continuous furnace, the quenching temperature is 930°C, the holding temperature deviation is ±10°C, and the holding time is 2.5h;

[0094] The third step: the quenching of the bar is cooled by water-air alternate time control method, the surface temperature of the bar is not higher than 260 ℃, and air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com