A high-strength tungsten-containing nickel-based superalloy material and its preparation method and application

A technology of nickel-based superalloy and superalloy, which is applied in the field of high-strength tungsten-containing nickel-based superalloy materials and its preparation, can solve the problems of inability to guarantee high-temperature durability, influence of alloy strength, and increase cost, etc., and achieve suitable promotion Use, excellent high-temperature strength performance, and the effect of reducing impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]A high-strength tungsten-containing nickel-based superalloy material, its element composition includes: C0.07%, Cr 17.15%, Mo 2.95%, Co 6.18%, W 6.10%, Al 1.70%, Nb 0.75% by weight percentage %, Fe 14.7%, and the balance being Ni and unavoidable impurities.

[0032] The preparation method of above-mentioned superalloy material is as follows:

[0033] (1) Weigh the smelting raw materials containing the above elements according to the proportion of each element, put the raw materials into the smelting furnace (vacuum induction furnace), and carry out the initial smelting in a vacuum atmosphere of 50Pa. The initial smelting temperature is 1580°C, and the initial smelting melting speed is 1.0kg / min, add dolomite and lime (weight ratio is 2:1) slag making in the molten steel process of initial stage, the total weight of slagging agent is 3.6% of described raw material weight, after raw material melting clear, carry out slag;

[0034] (2) When the raw material of step (1) me...

Embodiment 2

[0041] A high-strength tungsten-containing nickel-based superalloy material, its element composition includes: C0.09%, Cr 19.35%, Mo 3.25%, Co 7.28%, W 6.30%, Al 1.80%, Nb 1.05% by weight percentage %, Fe 16.3%, and the balance being Ni and unavoidable impurities.

[0042] The preparation method of above-mentioned superalloy material is as follows:

[0043] (1) Weigh the smelting raw materials containing the above elements according to the proportion of each element, put the raw materials into the smelting furnace (vacuum induction furnace), and carry out the initial smelting in a vacuum atmosphere of 55Pa. The initial smelting temperature is 1590°C, and the initial smelting melting speed is 1.5kg / min, add dolomite and lime (weight ratio is 3:2) to make slagging in the molten steel process of initial stage, the total weight of slagging agent is 4.5% of described raw material weight, after raw material melting clear, carry out slag;

[0044] (2) When the raw material of step ...

Embodiment 3

[0051] A high-strength tungsten-containing nickel-based superalloy material, by weight percentage, its element composition includes: C0.08%, Cr 18.25%, Mo 3.15%, Co 6.88%, W 6.20%, Al 1.77%, Nb 0.96 %, Fe 15.8%, and the balance being Ni and unavoidable impurities.

[0052] The preparation method of above-mentioned superalloy material is as follows:

[0053] (1) Weigh the smelting raw materials containing the above elements according to the proportion of each element, put the raw materials into the smelting furnace (vacuum induction furnace), and carry out the initial smelting in a vacuum atmosphere of 56Pa. The initial smelting temperature is 1585 ° C, and the initial melting speed is 1.2kg / min, add dolomite and lime (weight ratio is 5:6) slagging in the molten steel process of initial stage, the total weight of slagging agent is 3.8% of described raw material weight, after raw material is smelted, remove slag;

[0054] (2) When the raw material of step (1) melts more than 7...

PUM

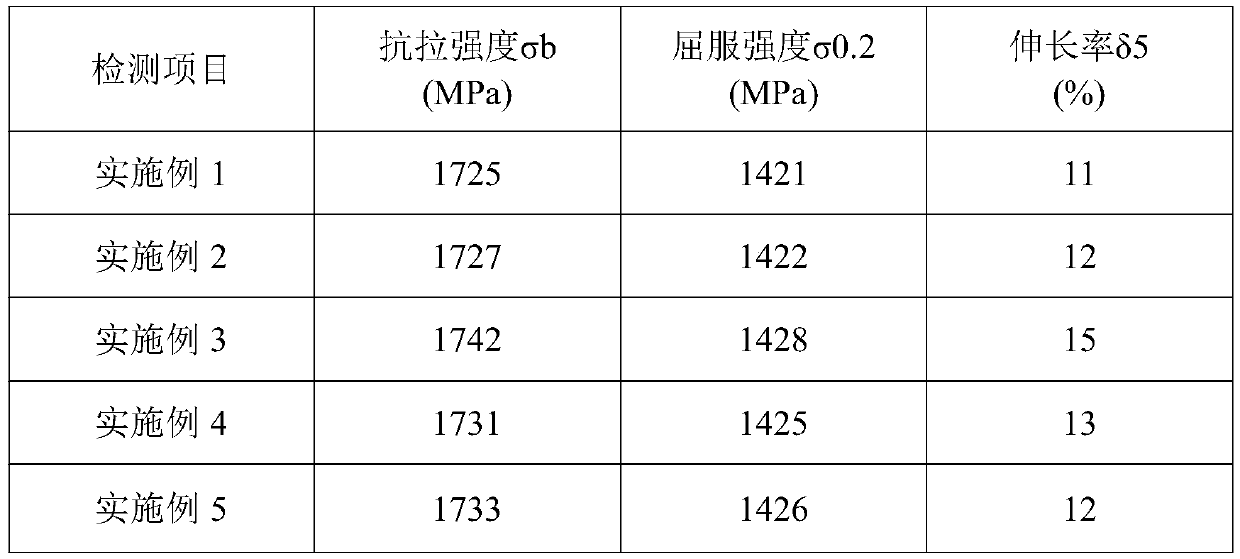

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com