Low-cr ferritic stainless steel with excellent formability and high temperature properties, and manufacturing method therefor

A technology of high-temperature characteristics and manufacturing methods, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of poor high-temperature strength and high-temperature oxidation resistance, and rising manufacturing costs, and achieve excellent high-temperature strength characteristics, prevent formability, improve Effect of High Temperature Oxidation Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0034] Hereinafter, embodiments of the present disclosure will be described in detail with reference to the accompanying drawings. The following embodiments are provided to convey the technical idea of the present disclosure to those of ordinary skill in the art. However, the present disclosure is not limited to these embodiments, and may be embodied in other forms. In the drawings, in order to clearly explain the present disclosure, parts irrelevant to the description may not be shown, and furthermore, the size of components is more or less exaggerated for easy understanding.

[0035] Furthermore, when a part "includes" or "includes" an element, unless there is a description specifically to the contrary, the part may also include other elements, and other elements are not excluded.

[0036] Expressions used in the singular include plural expressions unless there are clearly different meanings in the context.

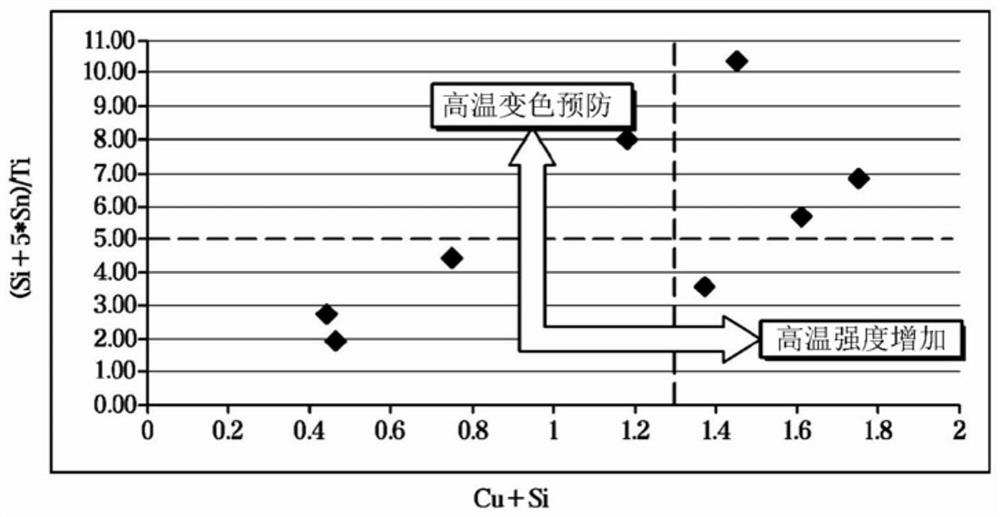

[0037] As a result of conducting various studies to improve hi...

Embodiment

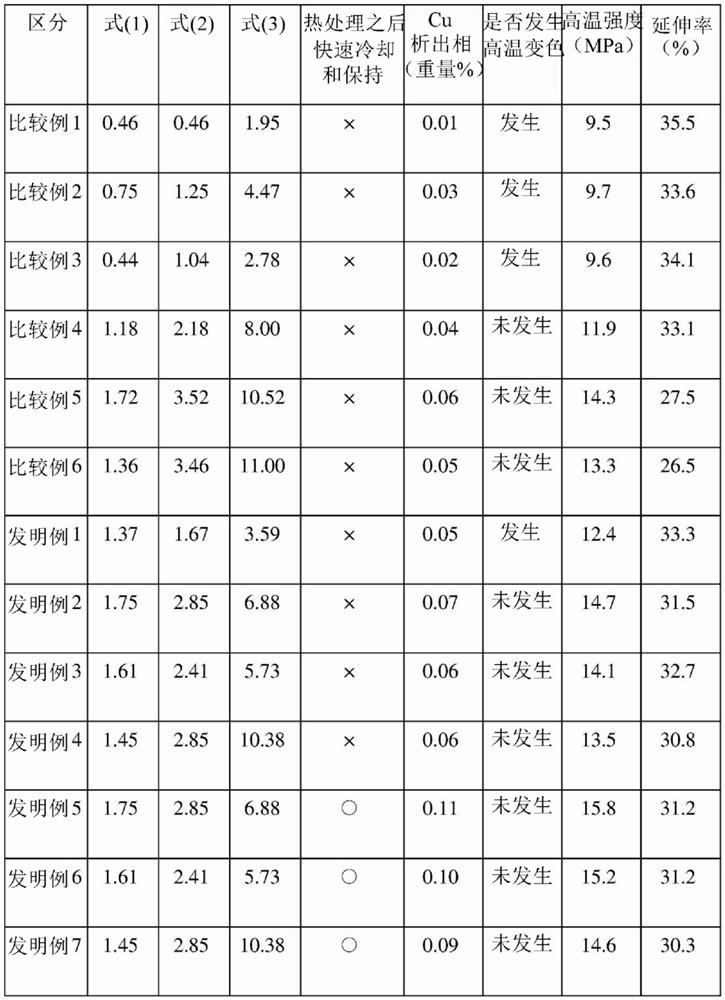

[0081] Using stainless steel laboratory scale melting and ingot production equipment, 20 mm bar samples were prepared with the alloy composition system shown in Table 1 below. After reheating at 1200°C and hot rolling to 6 mm, hot rolling annealing was performed at 1100°C. And after cold rolling to 2.0 mm, annealing heat treatment was performed at 1100°C. For some inventive examples only, cold-rolled and annealed steel sheets were produced by rapid cooling to 500° C., holding for 7 minutes, and air cooling after heat treatment. The remaining inventive examples and comparative examples were subjected to air cooling after the annealing heat treatment.

[0082]

[0083] distinguish C N Si mn Cr Ti Cu Al sn Comparative example 1 0.005 0.010 0.41 0.21 11.4 0.21 0.05 0.02 0 Comparative example 2 0.006 0.008 0.6 0.21 12.1 0.19 0.15 0.02 0.05 Comparative example 3 0.007 0.007 0.2 0.21 11.1 0.18 0.24 0.03 0.06 Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com