Preparation and molding process of a high-strength nickel-based superalloy

A nickel-based superalloy and forming process technology, which is applied in the field of high-strength nickel-based superalloy preparation and forming process, can solve the problems of reducing the thermal processing performance of the alloy, increasing the difficulty of alloy preparation and forming, and endangering the stability of the alloy structure, so as to achieve excellent strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

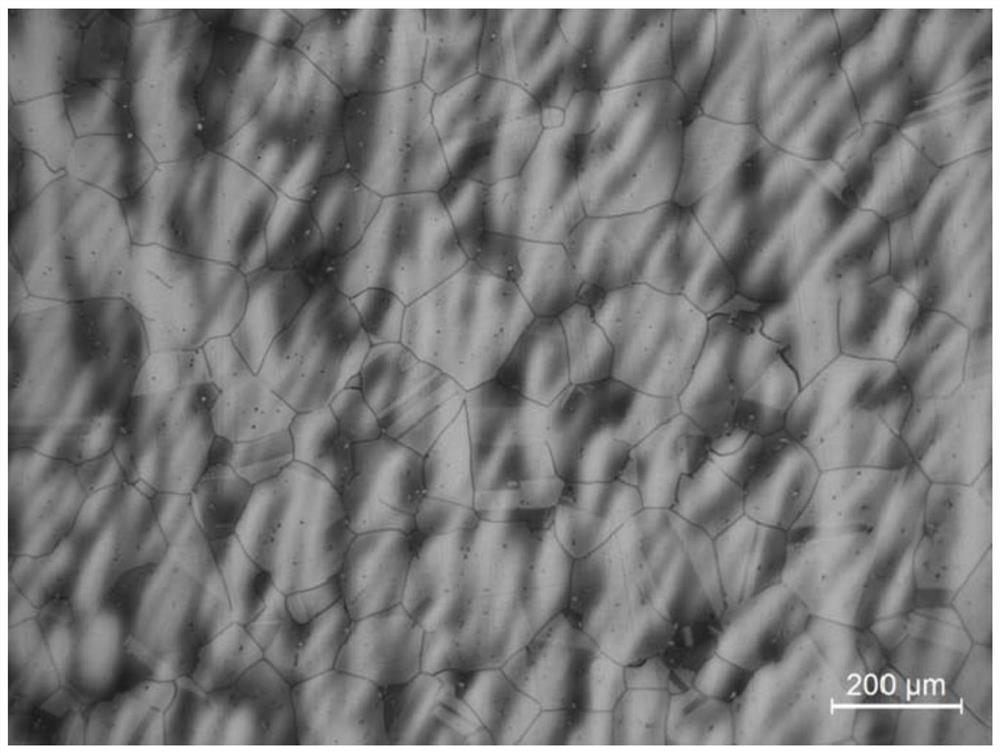

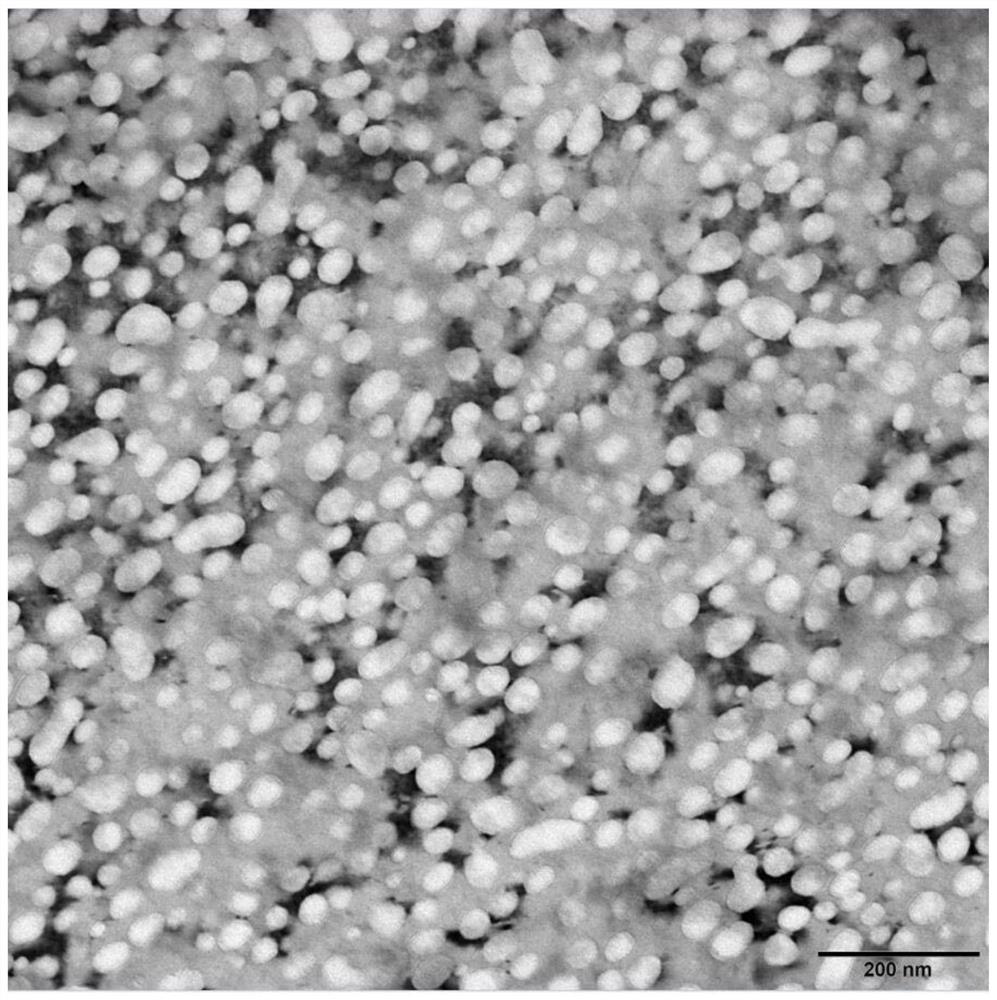

Embodiment 1

[0034] The heat-resistant steel material of this embodiment includes by mass percentage: Cr: 17%, Co: 20%, Ti: 1.5%, Al: 4.5%, W: 8.5%, Si: 0.2%, Mn: 0.3%, Nb: 1.5%, C: 0.06%, the balance being Ni;

[0035] The forming preparation process of this embodiment includes three steps of alloy smelting, billet forging and heat treatment:

[0036] 1) Alloy smelting: Vacuum induction melting furnace is used to smelt the prepared alloy raw materials, and when the vacuum reaches the range of 0.35Pa, high-purity argon gas is introduced and smelted. Among them, magnesium oxide basic furnace lining is used for alloy smelting, pure nickel is used to wash the furnace before smelting, and shot blasting is carried out before alloy raw materials are added to ensure that the P and S contents in the later stage of alloy smelting are not higher than 0.03%;

[0037] 2) Blank forging: heat the ingot at a rate of 10°C / min to 1200°C for homogenization treatment, and then carry out blank forging at 118...

Embodiment 2

[0043] The heat-resistant steel material of this embodiment includes by mass percentage: Cr: 16%, Co: 20%, Ti: 1.2%, Al: 4.2%, W: 10%, Si: 0.3%, Mn: 0.3%, Nb: 1.0%, C: 0.05%, the balance being Ni;

[0044] The preparation and molding process of this embodiment includes three steps of alloy smelting, billet forging and heat treatment:

[0045] 1) Alloy smelting: Vacuum induction melting furnace is used to smelt the prepared alloy raw materials, and when the vacuum reaches the range of 0.35Pa, high-purity argon gas is introduced and smelted. Among them, magnesium oxide basic furnace lining is used for alloy smelting, pure nickel is used to wash the furnace before smelting, and shot blasting is carried out before alloy raw materials are added to ensure that the P and S contents in the later stage of alloy smelting are not higher than 0.03%;

[0046] 2) Blank forging: heat the ingot at a rate of 10°C / min to 1200°C for homogenization treatment, and then carry out blank forging at ...

Embodiment 3

[0049] 1) Alloy smelting: vacuumize first, and then smelt the alloy raw material in a vacuum induction melting furnace with magnesium oxide basic furnace lining under the protection of argon to obtain ingots; wherein, the alloy raw material is calculated by mass percentage, including: Cr: 16%, Co: 20%, Ti: 0.5%, Al: 3.5%, W: 10%, Si: 0.5%, Mn: 0.5%, Nb: 0.5%, C: 0.03%, the balance is Ni;

[0050] 2) Blank forging: heat the ingot at 950°C for 1.5 hours, then heat the ingot from room temperature to 1180°C at a rate of 10°C / min for 15 hours, and then carry out blank forging at 1180°C. The amount of deformation for each time is 15%. After the billet forging is completed, it is returned to the furnace for heat preservation. The heat preservation time T and the time outside the furnace t satisfy 10t≤T, and the total deformation is not less than 70%;

[0051] 3) Heat treatment: heat the alloy after blank forging at 1150°C for 2.0 hours, then air cool at 980°C for 1.5 hours, then hold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com