Food-grade high wear-resistant martensitic stainless steel material and preparation method thereof

A martensitic stainless steel, high wear-resistant technology, applied in the field of stainless steel materials, can solve the problems of inconvenience to consumers, increased cost of manufacturers, and easy scratches on stainless steel tableware

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

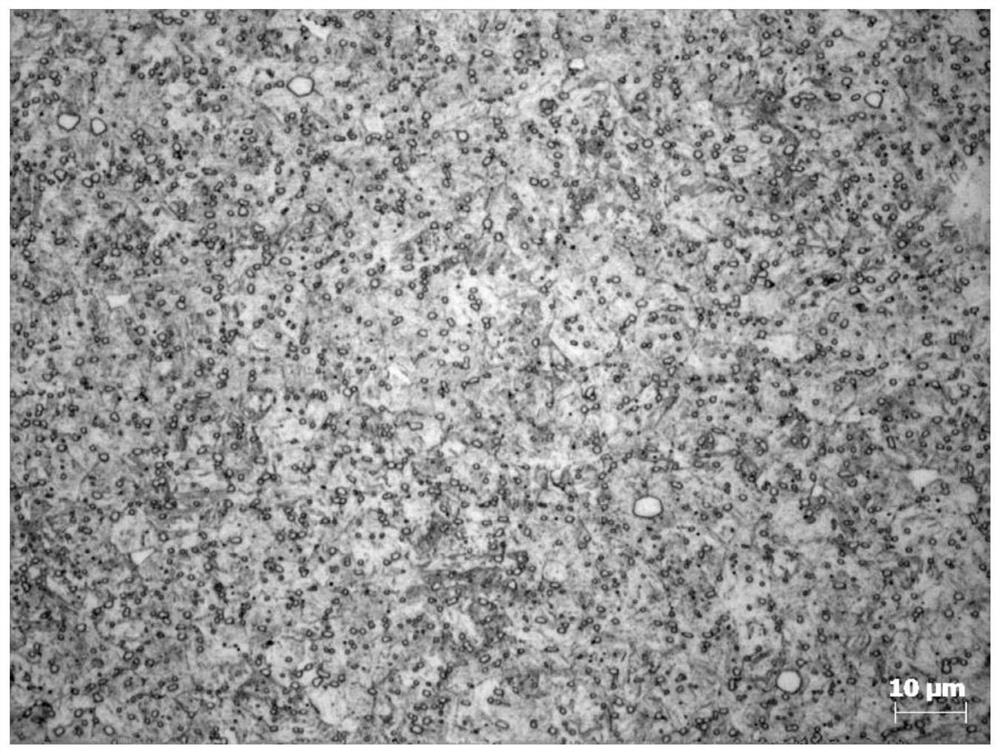

Image

Examples

Embodiment Construction

[0038] The following examples will further illustrate the present invention, but do not limit the present invention thereby. The steels in the examples and the steels in the comparative examples were smelted, heat-processed and heat-treated to be tested for surface hardness, corrosion resistance, antibacterial performance and heavy metal migration.

[0039] Rockwell indentation method is used for hardness test, the load is 150kgf, and the holding time is 15s.

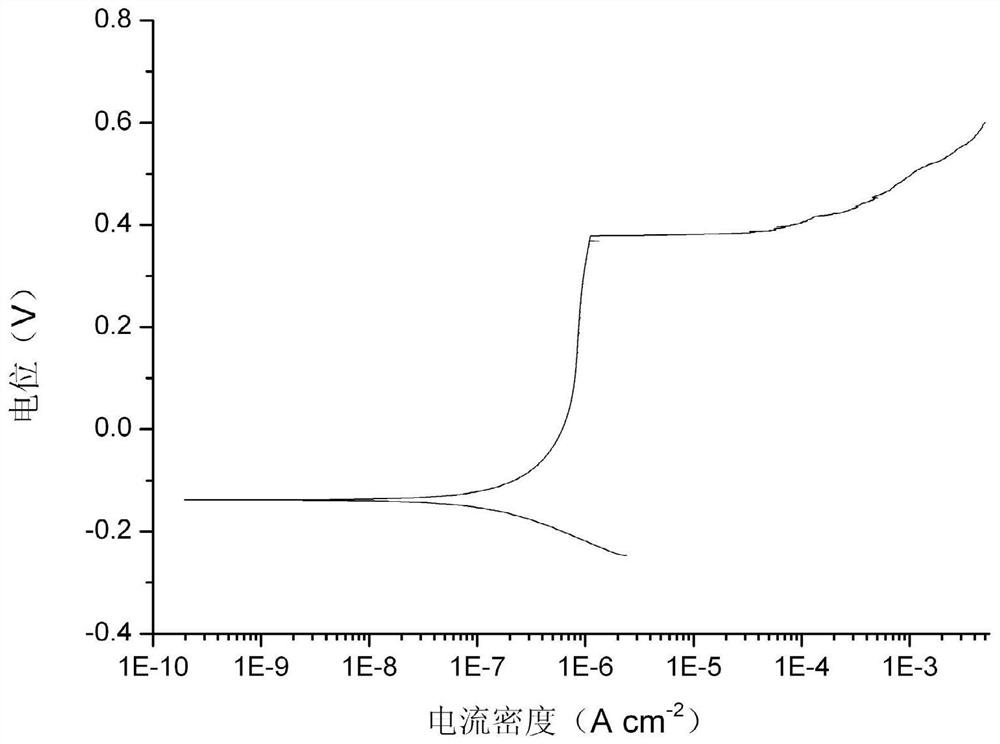

[0040] The polarization curve test was carried out on stainless steel, the reference electrode was KCl saturated calomel electrode, the scanning speed was 0.5mV / s, and the electrolyte solution was 0.9% NaCl solution. By testing the pitting potential of different examples, their corrosion resistance was investigated.

[0041] The antibacterial performance is tested according to the standard of GB / T2591-2003 "Experimental method and antibacterial effect of antibacterial plastic antibacterial performance". The calculatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com