Compaction embroidering system for honeycomb porous-structure cotton and use method thereof

A technology of porous structure and honeycomb, which is applied in needle looms, non-woven fabrics, textiles and papermaking, etc. It can solve the problems of finishing and compacting textiles, achieve good results, improve compacting effects, and facilitate weaving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

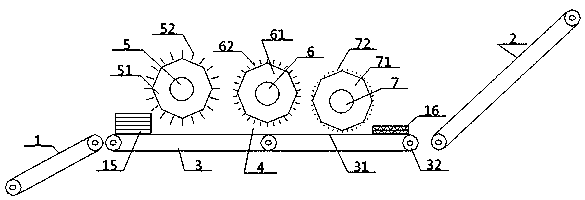

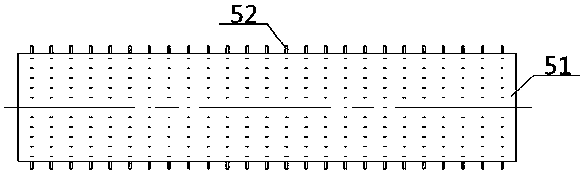

[0052] see Figure 1 to Figure 7 , a compacting and weaving system for cotton with a honeycomb porous structure, including a main conveying device 3 and a finishing device 4, the main conveying device 3 includes a main conveying belt 31 and a main conveying roller 32 connected to each other, and the main conveying belt 31 The finishing device 4 is arranged directly above the middle part; the finishing device 4 includes a No. 1 licker-in roller 5, a No. 2 licker-in roller 6, and a No. Licker-in 5, No. 2 licker-in 6, and No. 3 licker-in 7 are all located directly above the main conveyor belt 31; the No. 1 licker-in 5 includes a No. 1 roller body 51 and a plurality of No. 1 licker-in rollers uniformly arranged along its side circumference. Needles 52, the No. 2 licker-in roller 6 includes a No. 2 roller body 61 and a plurality of No. 2 licker-in needles 62 uniformly arranged along its side circumference, and the No. 3 licker-in roller 7 includes a No. 3 roller body 71 and a numbe...

Embodiment 2

[0055] Basic content is the same as embodiment 1, the difference is:

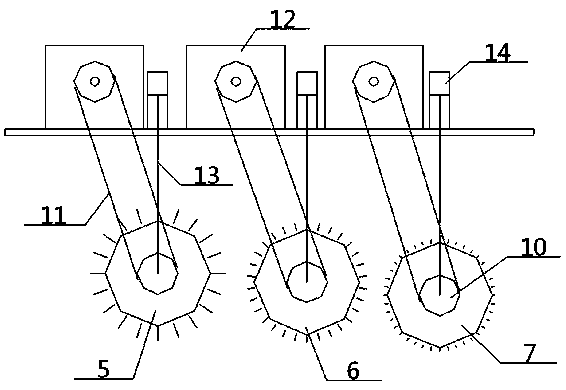

[0056] The ends of the No. 1 roller body 51, the No. 2 roller body 61, and the No. 3 roller body 71 are all provided with a rotary drive shaft 10, and the outer side of the rotary drive shaft 10 is surrounded by the output of the rotary transmission belt 11 and the rotary drive motor 12. end carries out transmission fit, and the center position of rotating drive shaft 10 is connected with the output end of lifting motor 14 by lifting rope 13.

[0057] In the process of conveying and passing by, carry out any one or all of the following operations: the first: change the rotation direction of the No. 1 roller body 51, the No. 2 roller body 61, and the No. 3 roller body 71 by rotating the transmission belt 11 Or rotation speed or change simultaneously; The second kind: change the height of No. 1 roller body 51, No. 2 roller body 61, and No. 3 roller body 71 by hoisting rope 13.

Embodiment 3

[0059] Basic content is the same as embodiment 1, the difference is:

[0060] The distribution density of the No. 1 needle 52 on the side circumference of the No. 1 roller body 51 is smaller than the distribution density of the No. 2 needle 62 on the side circumference of the No. 2 roller body 61, and the distribution density of the No. 2 needle 62 on the side circumference of the No. The distribution density is smaller than the distribution density of No. 3 needles 72 on the side circumference of No. 3 roller body 71 . The length of the first needle 52 is greater than that of the second needle 62 , and the length of the second needle 62 is greater than the length of the third needle 72 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com