Steel-plastic conversion part air tightness detection device

A technology of air tightness detection and steel-plastic conversion, which is applied in fluid tightness testing, liquid tightness measurement using liquid/vacuum degree, machine/structural component testing, etc., which can solve heavy workload and low work efficiency , Bend pipe rubbing and other problems to achieve the effect of improving efficiency, reducing workload and increasing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

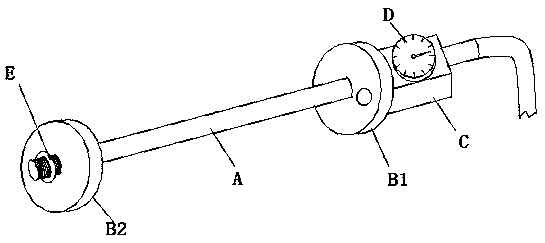

[0036] Example 1: Straight Pipe Tester

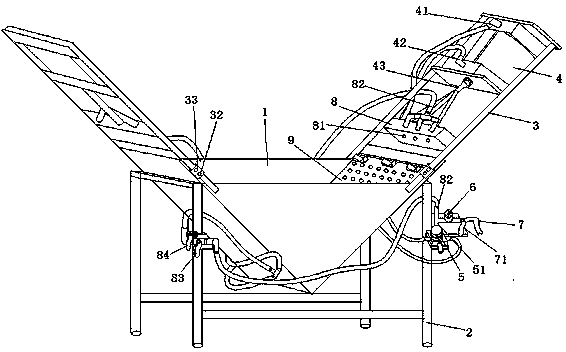

[0037] like Figure 2-3 Shown: an air-tightness detection device for a steel-plastic conversion piece, including a pool 1, a support foot 2 is fixedly connected to the bottom of the pool 1, and brackets 3 are arranged symmetrically on both sides of the upper side of the pool 1, taking the center line of the pool as a symmetrical axis; the The bracket 3 and the pool 1 are connected by the fixing member B33, and the fixing member B33 and the pool wall are welded and fixed; the fixing member B33 and the bracket 3 are fixed by the fastener 32, and the fastener between the bracket 3 and the fixing member B33 32 can be adjusted for tightness. When the length of the bracket 3 needs to be adjusted, loosen the fastener 32; when the bracket 1 and the fixing member B33 need to be fixed, tighten the fastener 32. The length of the bracket 3 can be adjusted according to the length of the detected piece.

[0038]A piston cylinder 4 is fixedly connec...

Embodiment 2

[0045] Example 2: Pipe bend tester

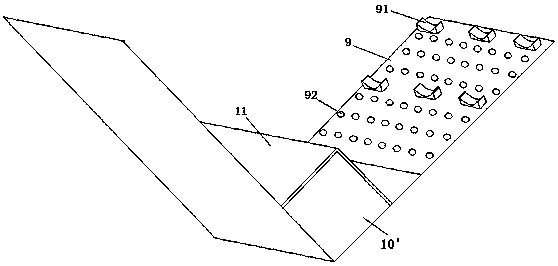

[0046] like Figure 4-5 As shown, in the pipe bend tester, slide rails 31 are respectively fixedly connected between two sides of the bracket 3 above the pool 1, the bracket 3 moves along the slide rail 31 through the slider, and the slider passes through the fixing member A and The slide rail 31 is fixed; the bracket 3 is oscillatingly connected to the slider through the fixing member B, so that the fixing member 33 can drive the bracket 3 to swing up and down to adjust the angle; 3. The length of the bracket 3 can be adjusted according to the length of the steel-plastic conversion piece.

[0047] The angle adjustment block 10 is a cushion block with a triangular side, (the angle and thickness of the cushion block are customized according to the angle of the bend pipe to be tested), and the cushion is placed between the "V"-shaped plate 9 and the inner wall of the pool 1, and the cushion has an angle. The included angle formed by the "V"...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com