Electronic complete machine storage life assessment and prediction method

A storage life and prediction method technology, which is applied in the field of system storage life extension research, can solve the problems of non-standard determination of storage life acceleration factor and storage time parameters of the electronic complete machine, and achieves easy engineering application, high fitting accuracy and simple calculation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

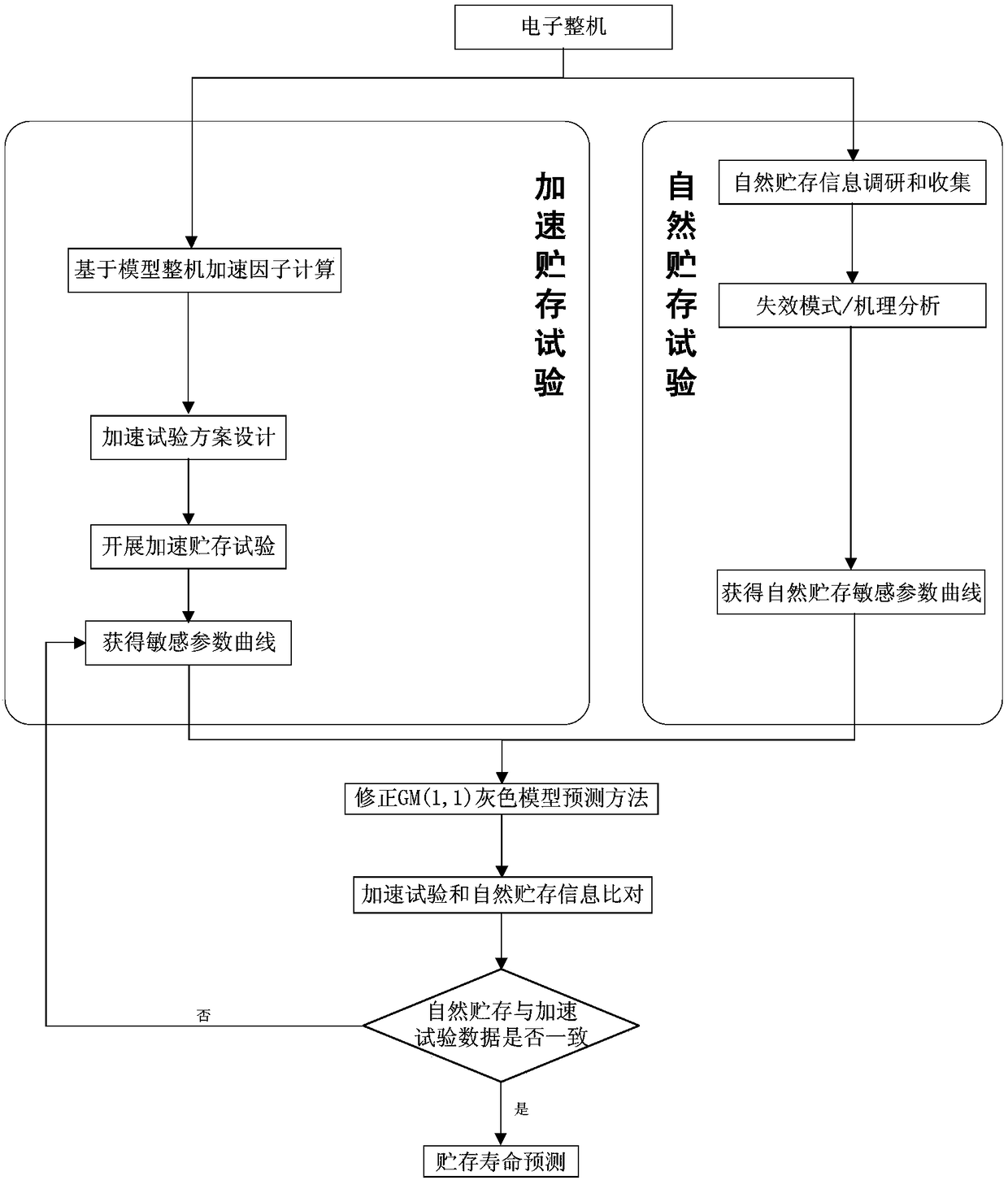

[0036] The invention provides a method for evaluating and predicting the storage life of a bomb-borne electronic complete machine, which combines figure 1 , including the following steps:

[0037] (1) The calculation method of the acceleration factor of the whole machine based on the component information, the steps are as follows:

[0038] Among the temperature stress accelerated test models, the most commonly used is the Arrhenius model:

[0039]

[0040] However, this model is only applicable to components and cannot be directly used for the whole machine. Based on this, a new method is proposed to calculate the "whole machine acceleration factor" by using component information:

[0041]

[0042] where A FT is the acceleration factor of the whole machine; λ AT is the overall average failure rate of equipment under accelerated stress; λ UT It is the total average failure rate of the equipment in actual use.

[0043] Since the sum of component failure rates is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com