Laser-triggered megavolt-level low-inductance gas switch

A gas switch and low inductance technology, which is applied in the field of megavolt low inductance gas switches, can solve the problems of large discharge inductance, easy insulation failure, and difficulty in implementing gas switch projects triggered by electric pulses, so as to improve the service life of the switch and reduce the Effect of switch inductance and avoidance trigger system insulation protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

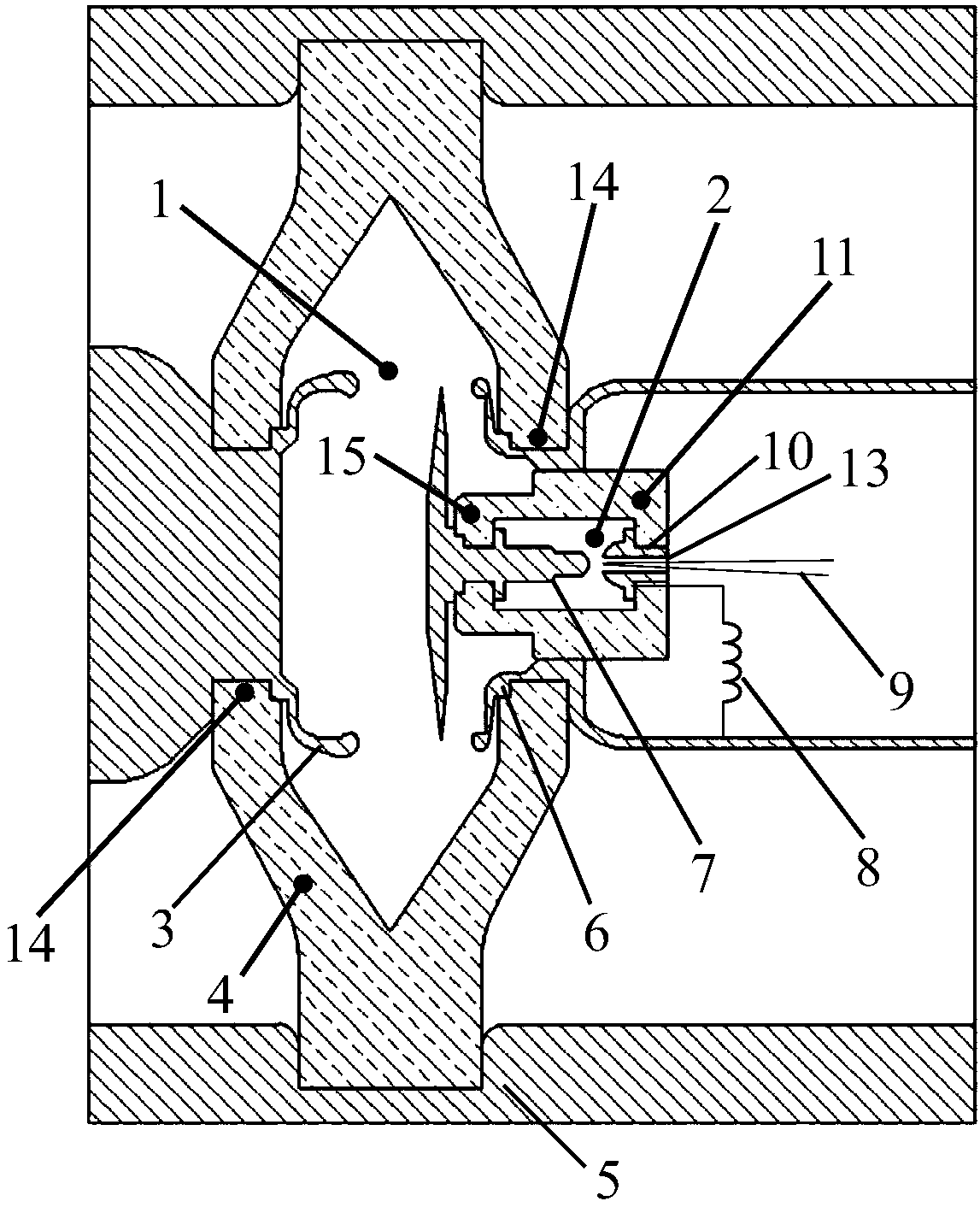

[0024] see figure 1 , the megavolt low-inductance gas switch triggered by the laser of the present invention includes a high-voltage electrode 3, a trigger electrode 7, a ground electrode 6, a hemispherical ground electrode 10, an outer cylinder 5, a first insulating mount 4, and a second insulating mount 11 and ground inductance 8.

[0025] The high-voltage electrode 3, the trigger electrode 7, the ground electrode 6, and the hemispherical ground electrode 10 are sequentially arranged in the middle of the outer cylinder 5 along the axial direction of the outer cylinder 5, and there is a set distance between any two of them; the high-voltage electrode 3 and the ground electrode The outer wall of 6 is provided with a first concave-convex portion 14 for positioning and installation; the trigger electrode 7 includes a disc-shaped portion and a rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com