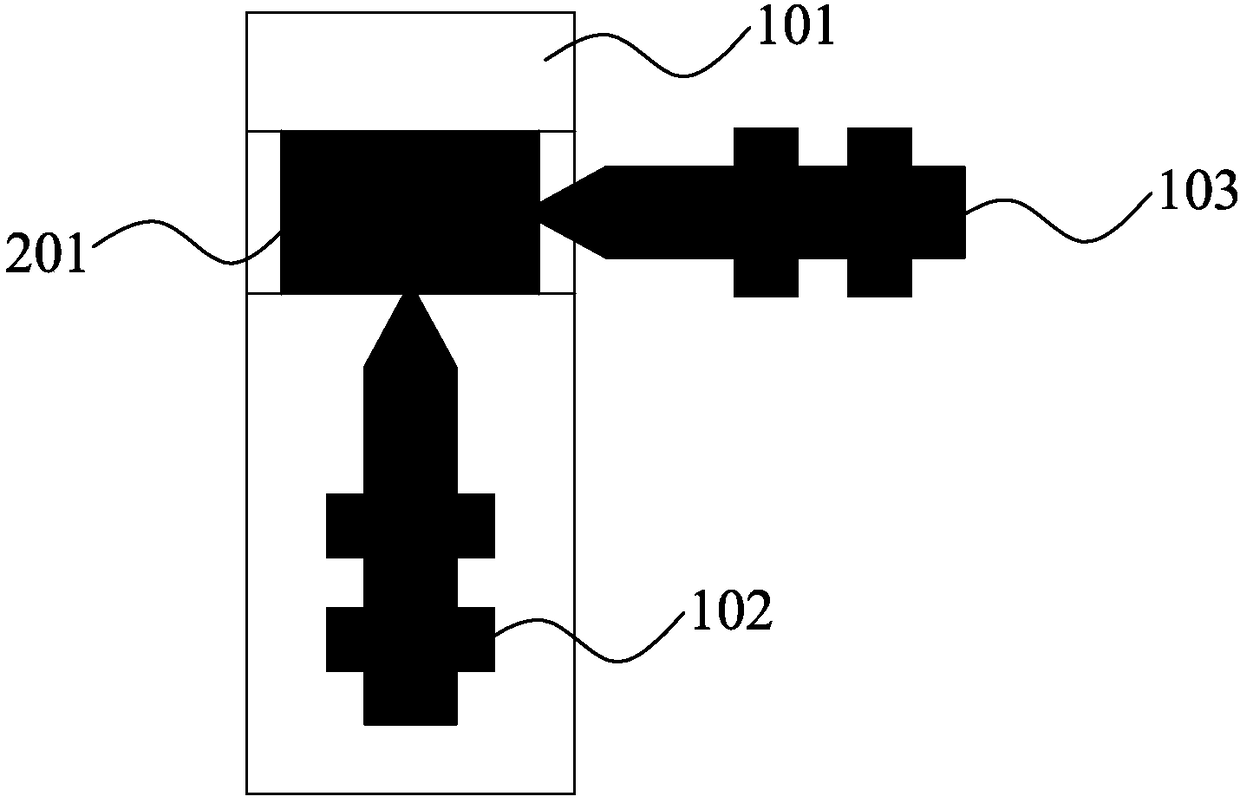

Two-material bonding apparatus, two-material bonding method and two-material bonding product

A technology that combines devices and products, and is applied to other household appliances, household components, household appliances, etc., which can solve the problems of poor mass production yield, poor product seam breakage, and inability to directly cover, so as to enhance the added value of products, The effect of good welding and improved coating adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

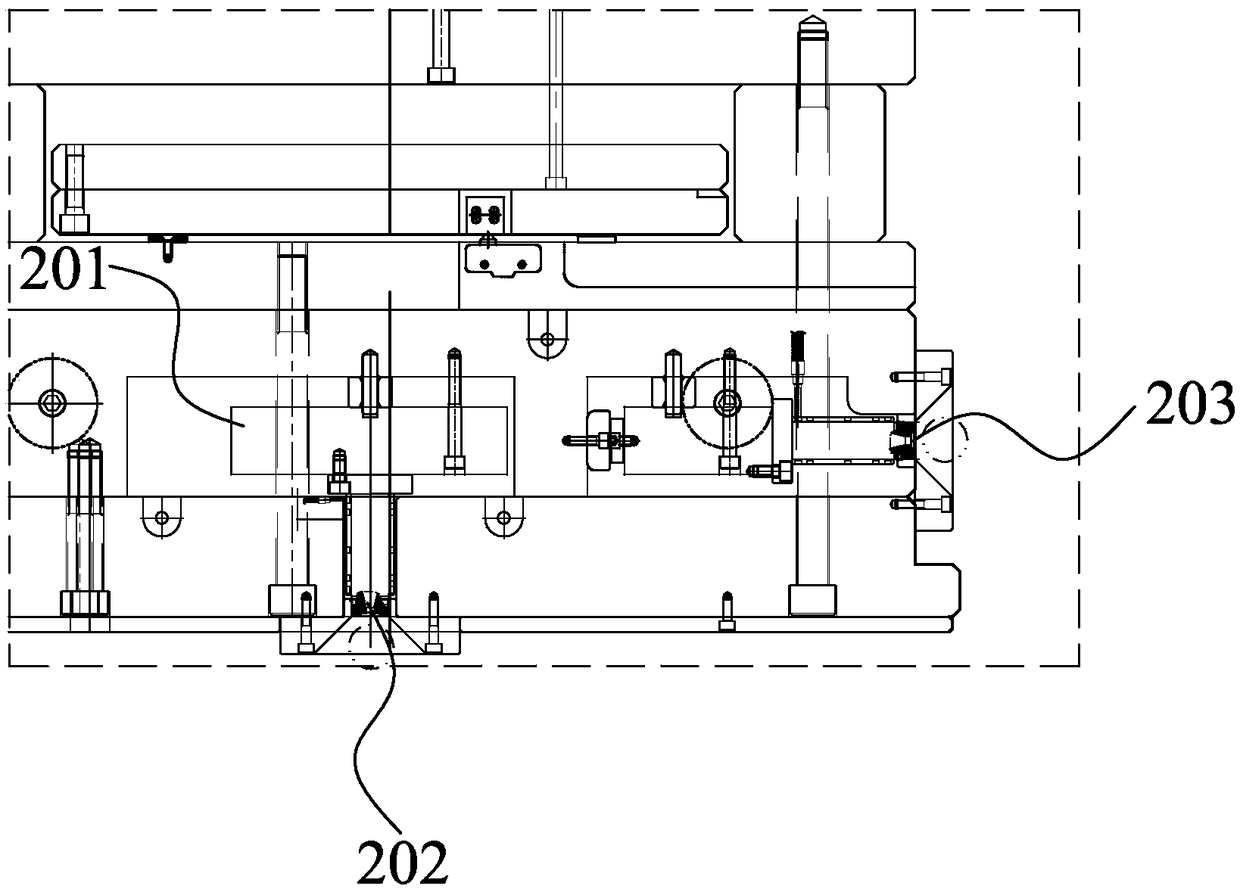

Method used

Image

Examples

Embodiment 1

[0055] Example 1: PC+20% CF&PC+50% GF co-injection molding

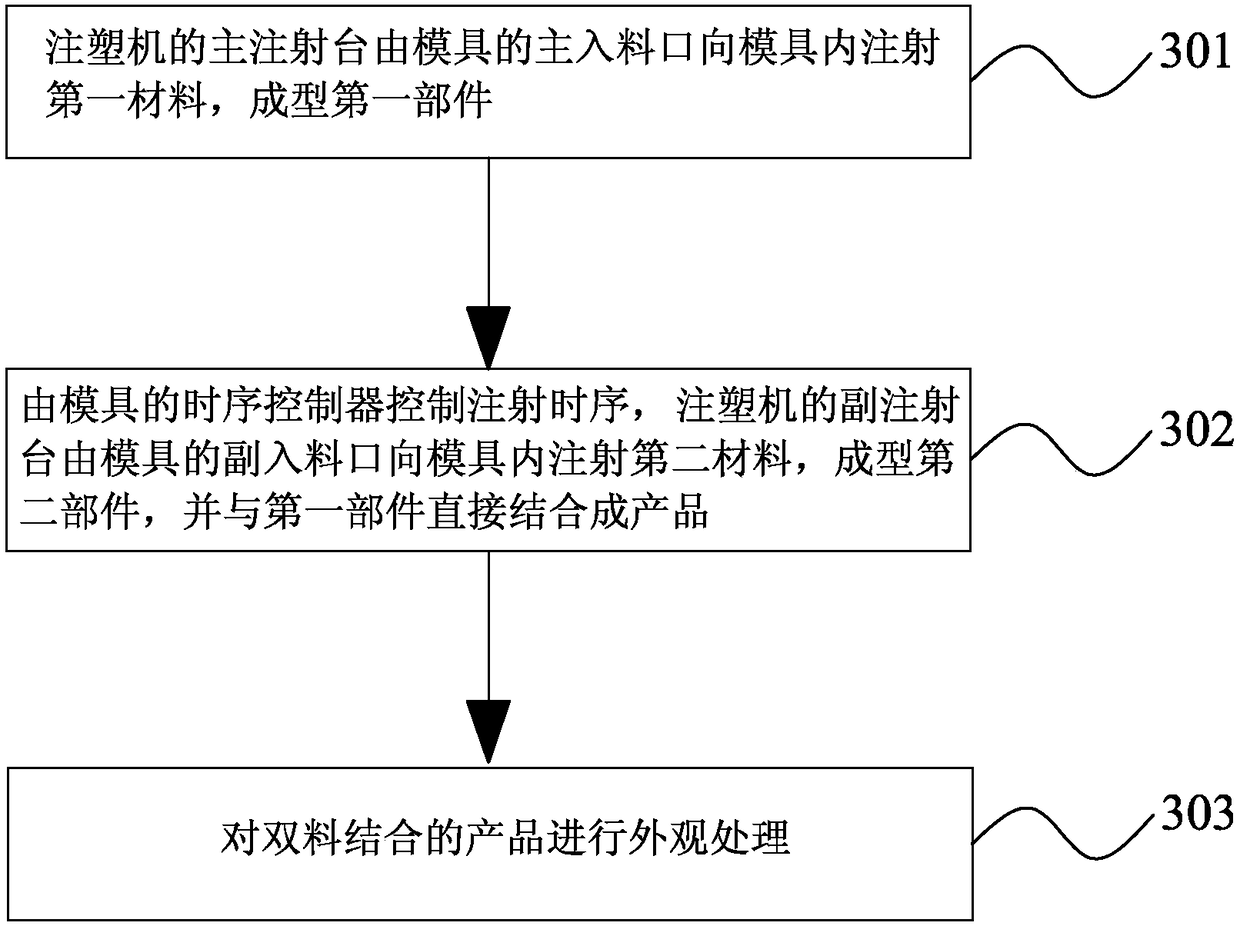

[0056] The first part adopts the first material (PC+20% CF) plastic pellets to be heated to 280-290 degrees, and is injection-molded on an injection molding machine equipped with a mold.

[0057] At the end of the injection of the first part, the high-rigidity plastic material PC+50% GF in the sub-injection station is delayed injection molding the second part from the sub-injection port in the same set of molds, and the two-material co-injection can be obtained. The product.

[0058] The products required by customers can be obtained through appearance treatment. Appearance treatment can be carried out by means of in-mold decoration (IMD: In-Mold Decoration), painting or out-mold decoration (OMD: Out Mold Decoration).

Embodiment 2

[0059] Example 2: PPA+20%CF&PPA+50%GF co-injection molding

[0060] The first part adopts the first material (PPA+20% CF) plastic pellets to be heated to 290-320 degrees, and is injection-molded on an injection molding machine equipped with a mold.

[0061] At the end of the injection of the first part, the high-rigidity plastic material PPA+50%GF in the sub-injection station is delayed injection molding the second part from the sub-injection port of the same mold, and the double-material co-injection can be obtained. The product.

[0062] The products required by customers can be obtained through appearance treatment, which can be done by painting or OMD (Out Molding Decoration).

Embodiment 3

[0063] Example 3: PPS+20%CF&PPS+45%GF co-injection molding

[0064] The first part adopts the first material (PPS+20% CF) plastic pellets to be heated to 300-320 degrees, and is injection-molded on an injection molding machine equipped with a mold.

[0065] At the end of the injection of the first part, the high-rigidity plastic material PPS+45%GF in the sub-injection station is delayed injection molding the second part from the sub-feed port in the same set of molds, and the double-material co-injection can be obtained. The product.

[0066] The products required by customers can be obtained through appearance treatment, which can be done by painting or OMD (Out Molding Decoration).

[0067] Please refer to Figure 4 , Figure 4 It is a schematic diagram showing the product structure of a preferred embodiment of the present invention.

[0068] In order to achieve the above object, the double-material combination product of the present invention is a product formed by the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com