Portable Tape Automatic Winder

A winder and portable technology, which is applied in the field of portable tape automatic winder, can solve the problems of increasing labor intensity of workers, substandard insulation performance, and reducing product yield, so as to reduce manual operation steps, reduce labor intensity, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

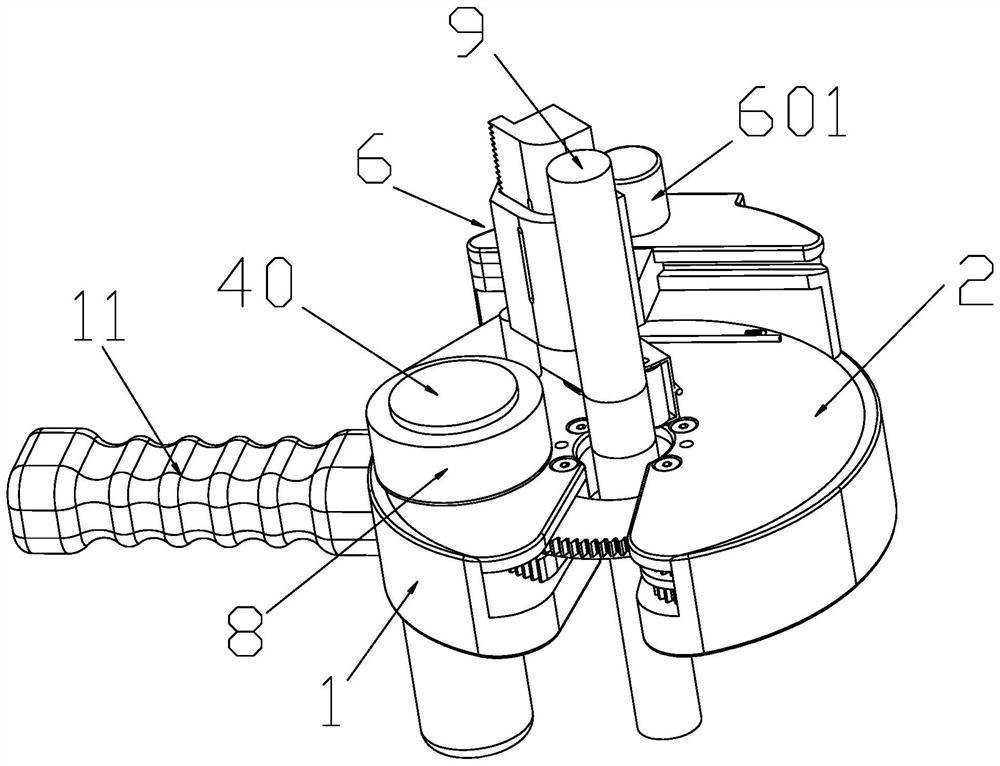

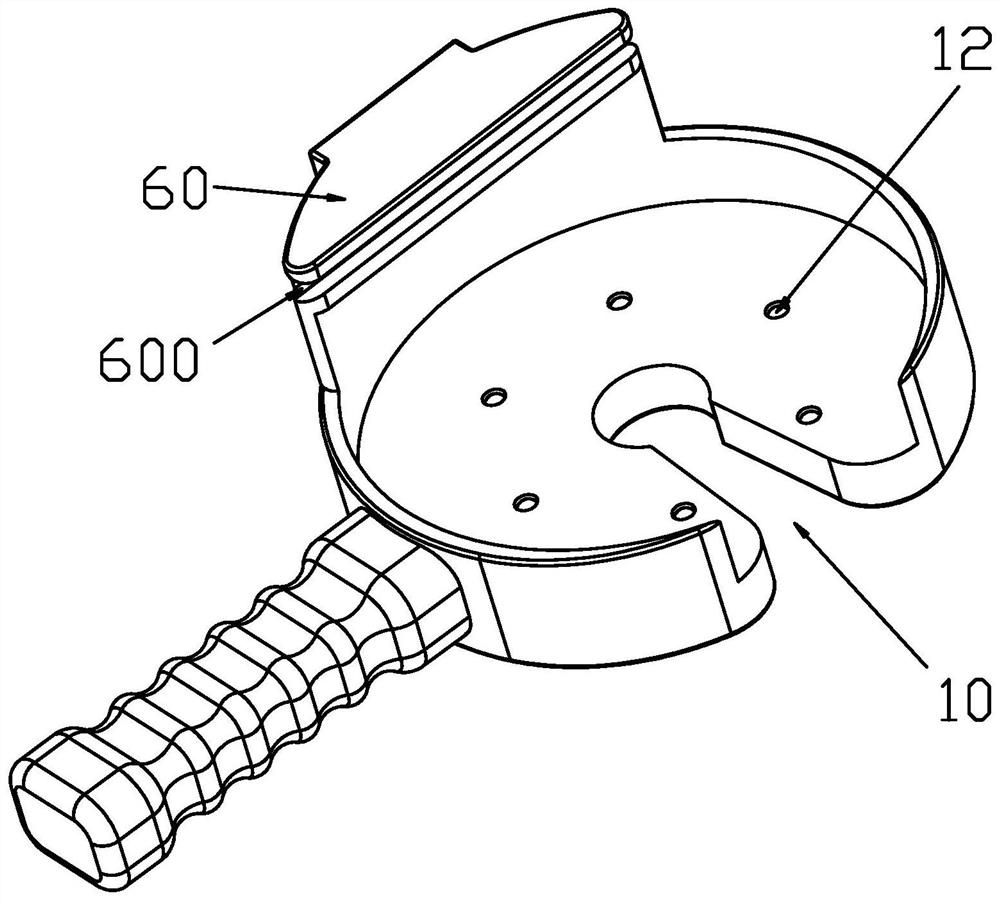

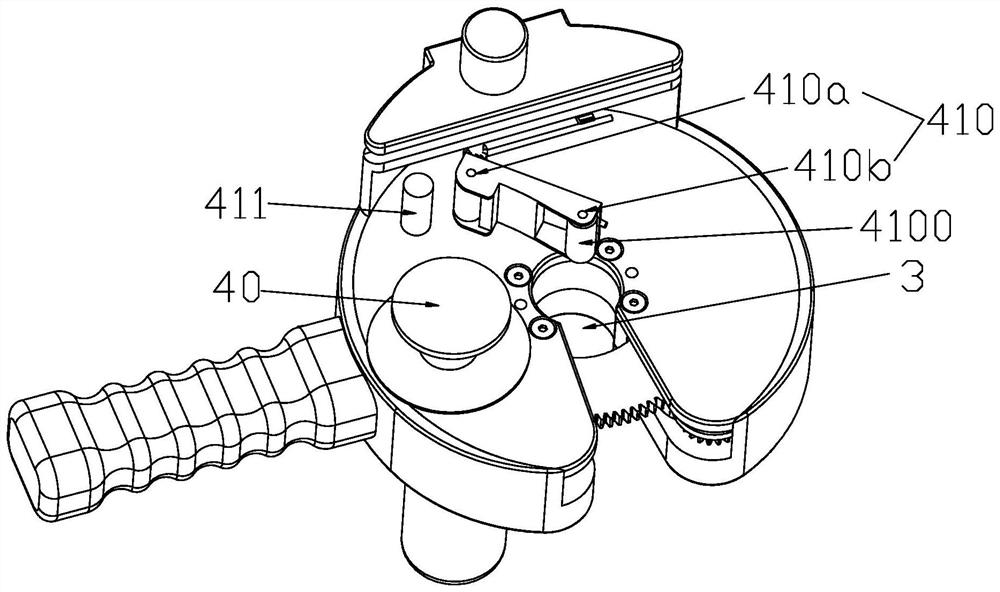

[0053] refer to Figure 1 to Figure 21 The tape automatic winder shown mainly includes a hollow cylindrical shell 1, the upper end of which is open, and a mounting plate 2 is provided for its internal rotation, and the mounting plate 2 is coaxially arranged with the shell 1, and the shell The body 1 is provided with a tape winding drive device 5, which is mainly used to drive the mounting plate 2 to rotate, and its rotation plane is parallel to the open end surface of the housing 1, and the mounting plate 2 is provided with a tape supply device.

[0054] refer to figure 2 , image 3 and Figure 6 , the center of the housing 1 and the mounting plate 2 are oppositely provided with a through hole, and the through hole penetrates both sides of the surface at the same time to form a wire harness through hole 3. When in use, the wire harness can pass through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com