Flip valve for semiconductor silicon single crystal furnace and single crystal furnace

A technology of silicon single crystal and flap valve, which is applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., and can solve the problem of not being able to maintain the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 provides an embodiment of a flap valve used in a semiconductor silicon single crystal furnace.

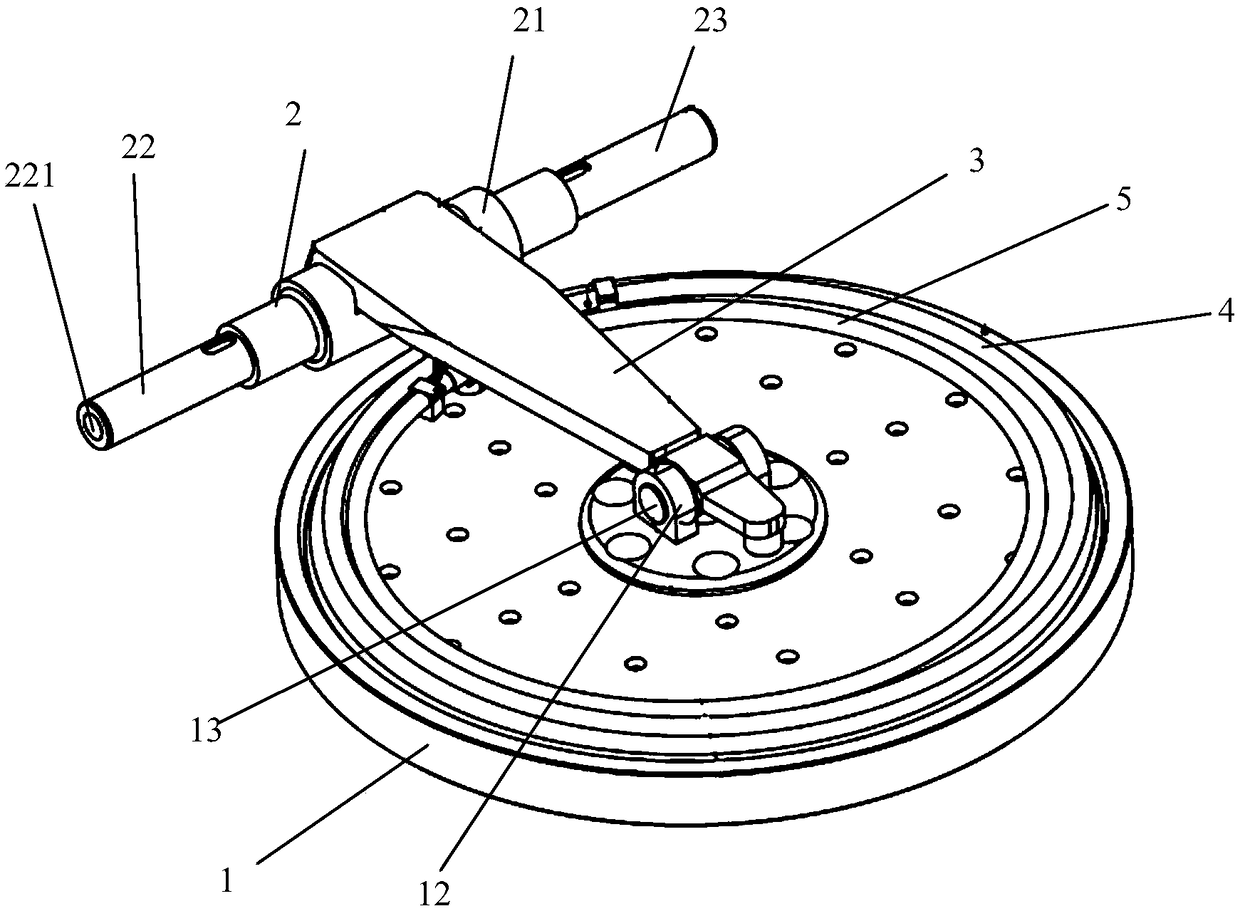

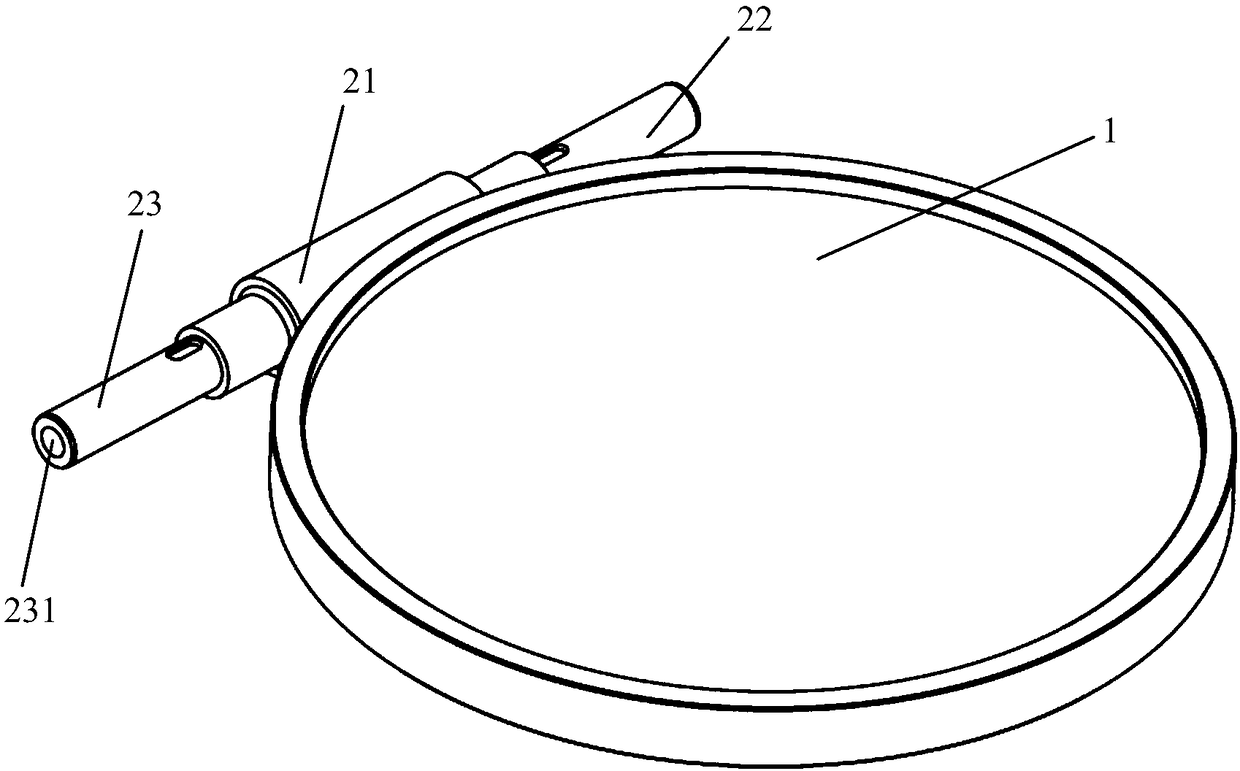

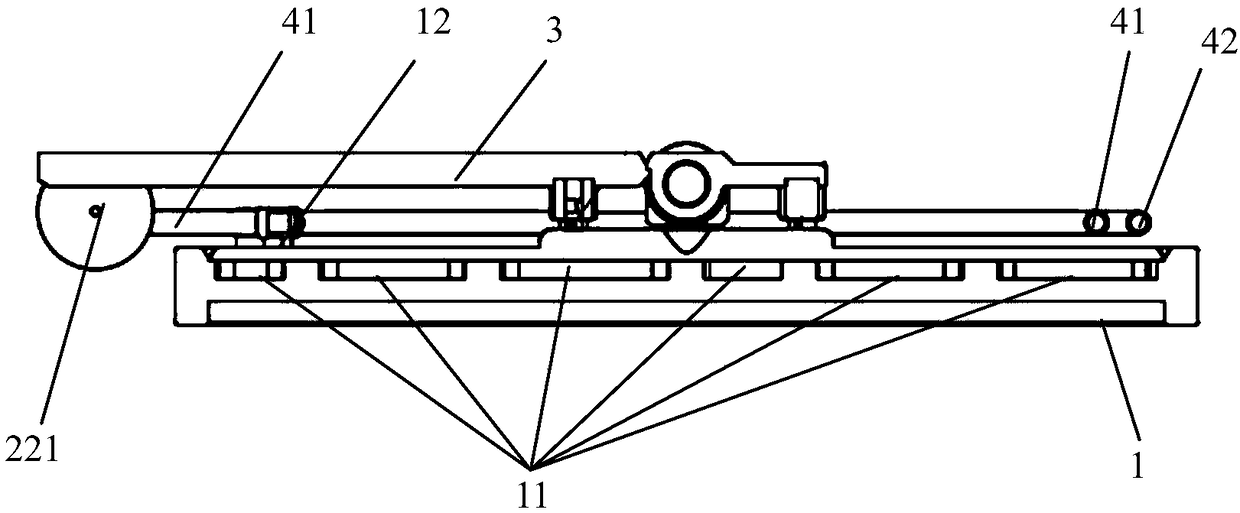

[0026] Please combine Figure 1 to Figure 4 As shown, a flap valve for a semiconductor silicon single crystal furnace includes a flap 1 , a flap shaft 2 , and a connecting plate 3 connecting the flip shaft 2 and the flap 1 . The turning shaft 2 includes a shaft sleeve 21 , a first shaft body 22 inserted at one end of the shaft sleeve 21 , and a second shaft body 23 inserted at the other end of the shaft sleeve 21 . The first shaft body 22 , the second shaft body 23 and the shaft sleeve 21 are arranged coaxially. The central position of the turnover plate 1 is provided with a pair of seat bodies 12 protruding upwards, and a rotating shaft 13 is arranged horizontally between the seat bodies 12. One end of the connecting plate 3 is fixedly connected to the shaft sleeve 21 and the connecting plate 3 The other end is hinged to the seat body 12 through a rotating sh...

Embodiment 2

[0033] The second embodiment provides a single crystal furnace including the flap valve mentioned above.

[0034] The single crystal furnace also includes a cooling water source (not shown), the cooling water source is connected to the water inlet channel of the first shaft body and injects cooling water into the water inlet channel of the first shaft body, and the cooling water passes through the water inlet channel in turn , water inlet pipe, water inlet elbow, water channel, drainage elbow, drainage pipe, drainage channel, and then discharged, that is, the heat in the flap can be taken away by cooling water to cool the flap valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com