Transmission type squeeze-dewatering device

A technology of extrusion dehydration and extrusion device, which is applied in the direction of liquid/gas/vapor removal with extrusion rollers, processing of textile material carriers, etc., which can solve problems such as trouble, increase work flow, dehydration, etc. Scope and selection, good effect of dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

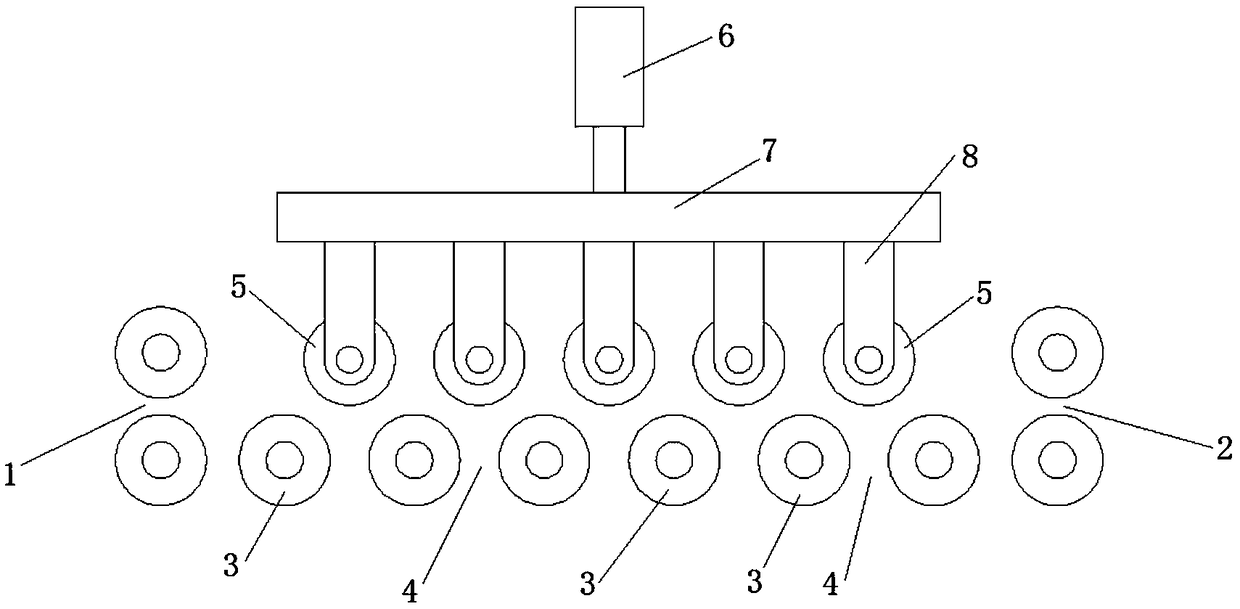

[0015] like figure 1 As shown in the figure, a transmission-type extrusion dehydration device includes a pair of twisted feed wheels 1 arranged at the front end of the left side, a pair of twisted discharge groups 2 arranged in parallel with the pair of twisted feed wheels 1 at the right rear end, and The middle transmission extrusion wheel group; the transmission extrusion wheel group includes a row of parallel transmission wheels 3 and the extrusion device; the transmission wheel 3 and the paired feeding wheel group 1 and the paired twisted discharging wheel group The pair of winches below 2 are arranged in parallel, and a section of squeeze gap 4 is set between adjacent transmission wheels 3, and a squeeze wheel 5 is arranged above the squeeze gap 4; the squeeze wheel 5 is installed On the extrusion device, the extrusion direction of the extrusion device is vertically downward, and the extrusion wheel 5 is driven to press on the corresponding two transmission wheels 3 below...

Embodiment 2

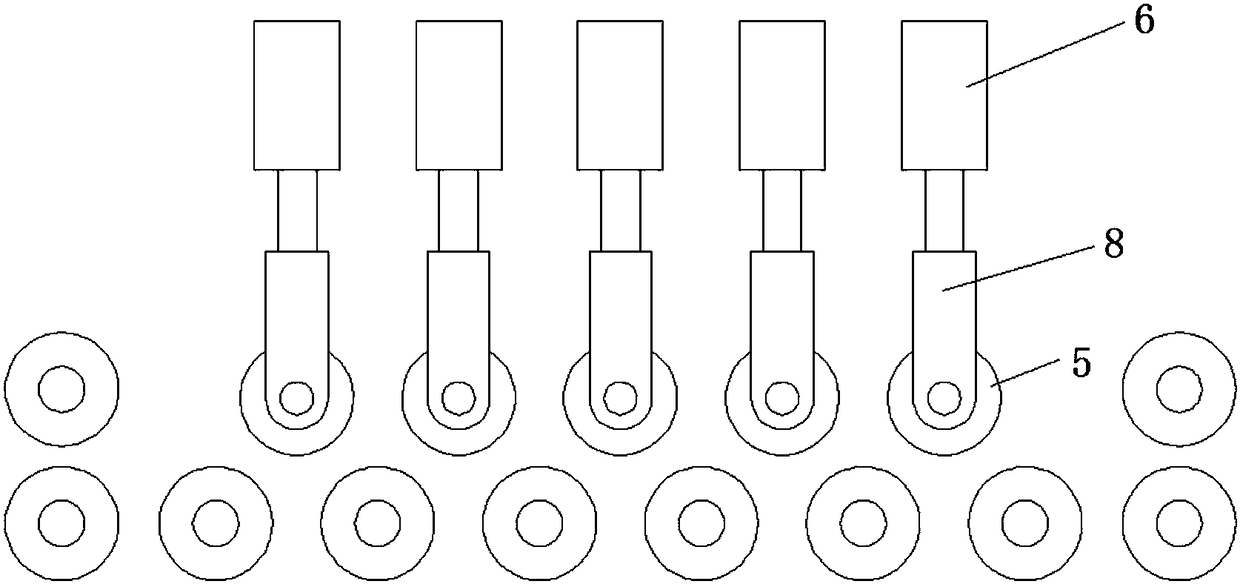

[0018] like figure 2 As shown in the figure, a transmission-type extrusion dehydration device includes a pair of twisted feed wheels 1 arranged at the front end of the left side, a pair of twisted discharge groups 2 arranged in parallel with the pair of twisted feed wheels 1 at the right rear end, and The middle transmission extrusion wheel group; the transmission extrusion wheel group includes a row of parallel transmission wheels 3 and the extrusion device; the transmission wheel 3 and the paired feeding wheel group 1 and the paired twisted discharging wheel group The pair of winches below 2 are arranged in parallel, and a section of squeeze gap 4 is set between adjacent transmission wheels 3, and a squeeze wheel 5 is arranged above the squeeze gap 4; the squeeze wheel 5 is installed On the extrusion device, the extrusion direction of the extrusion device is vertically downward, and the extrusion wheel 5 is driven to press on the corresponding two transmission wheels 3 belo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap