Vertical joint structure capable of avoiding extrusion damage of concrete panel and construction method

A technology of concrete panels and vertical joints, which is applied in water conservancy projects, marine engineering, buildings, etc., can solve the problems of reducing the safety of water stop between joints, panel extrusion damage, and the width is not increased, so as to avoid panel extrusion damage. , Avoid crushing damage, protect the effect of copper water stop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

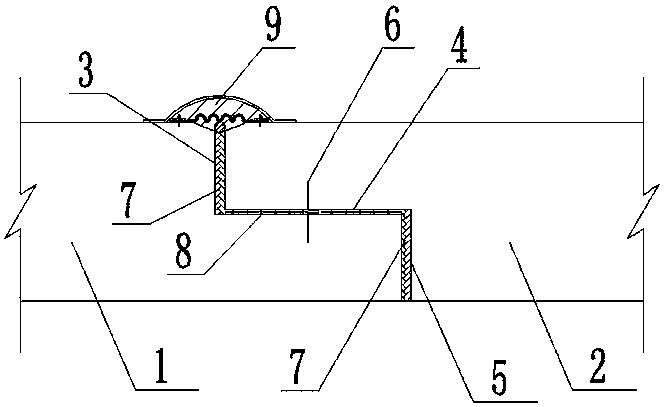

Embodiment 1

[0030] In order to solve the problem of increasing the width of the vertical seam to reduce the safety of the water stop between the seams, the width is not increased and it is easy to cause the problems caused by the panel extrusion damage. figure 1 Shown is a vertical joint structure to avoid the crushing damage of concrete panels, including concrete panel A1, concrete panel B2, copper sheet water stop 6, vertical pad 7, horizontal pad 8, surface water stop structure 9, in concrete There are gaps between the panel A1 and the concrete panel B2, including the upper wing side 3 of the vertical seam, the horizontal section 4 of the vertical seam, and the lower wing side 5 of the vertical seam. One side of the surface water stop structure 9 covers the upper surface of the concrete panel A1, and the other The side covers the upper surface of the concrete panel B2; the upper wing side 3 of the vertical seam and the lower wing side 5 of the vertical seam are arranged vertically, the ho...

Embodiment 2

[0033] On the basis of Example 1, the distance between the horizontal section 4 of the vertical seam and the upper surface of the concrete panel A1 and the concrete panel B2 is between 25 cm and one-half the thickness of the concrete panel. A1, the distance between the lower surface of the concrete panel B2 is between 25cm and one-half of the thickness of the concrete panel.

[0034] The length L of the horizontal section 4 of the vertical slit and the width W of the lower wing side 5 of the vertical slit satisfy the following relationship, and L is between 3 times and 20 times of W.

[0035] The widths of the upper wing side 3 and the lower wing side 5 of the vertical slit are the same, and the width of the horizontal section 4 of the vertical slit is between 1.2 cm and 2 cm.

[0036] One or more copper sheet water stoppers 6 are vertically arranged in the middle of the vertical seam horizontal section 4, and the copper sheet water stoppers 6 are made of red copper material.

[0037]...

Embodiment 3

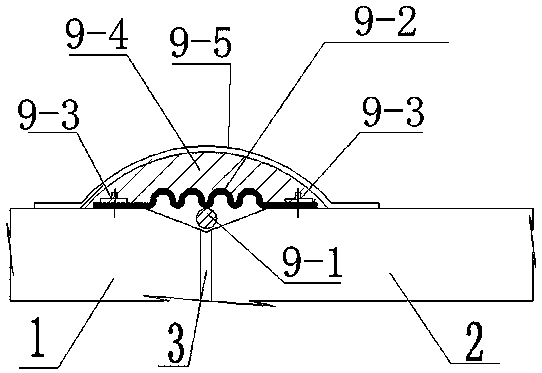

[0041] On the basis of Example 1 and Example 2, such as figure 2 As shown, the surface water stop structure 9 includes a rubber rod 9-1, a wave water stop 9-2, a galvanized expansion bolt 9-3, a plastic filler 9-4, and a surface water stop 9-5. The rubber The rod 9-1 is located at the bottom of the surface water stop structure 9 and is connected to the upper end of the upper wing side 3 of the vertical seam. The wave water stop 9-2 is a flat structure and is located on the top of the rubber rod 9-1. The wave water stop 9 -2 One end is fixed to the upper surface of concrete panel A1 by galvanized expansion bolts 9-3, and the other end is fixed to the upper surface of concrete panel B2 by galvanized expansion bolts 9-3. The middle of the wave waterstop 9-2 is wave Shaped structure, the surface waterstop 9-5 is semicircular, completely covering the entire wave waterstop 9-2, with horizontal ears on both sides, and the horizontal ears are respectively bonded to the concrete panel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com