Cofferdam lead hole slotting and grouting construction method for deepwater hard rock steel plate pile

A steel sheet pile cofferdam and construction method technology, which is applied to sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as high cost, difficult processing of cofferdams, and insufficient depth of steel sheet piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

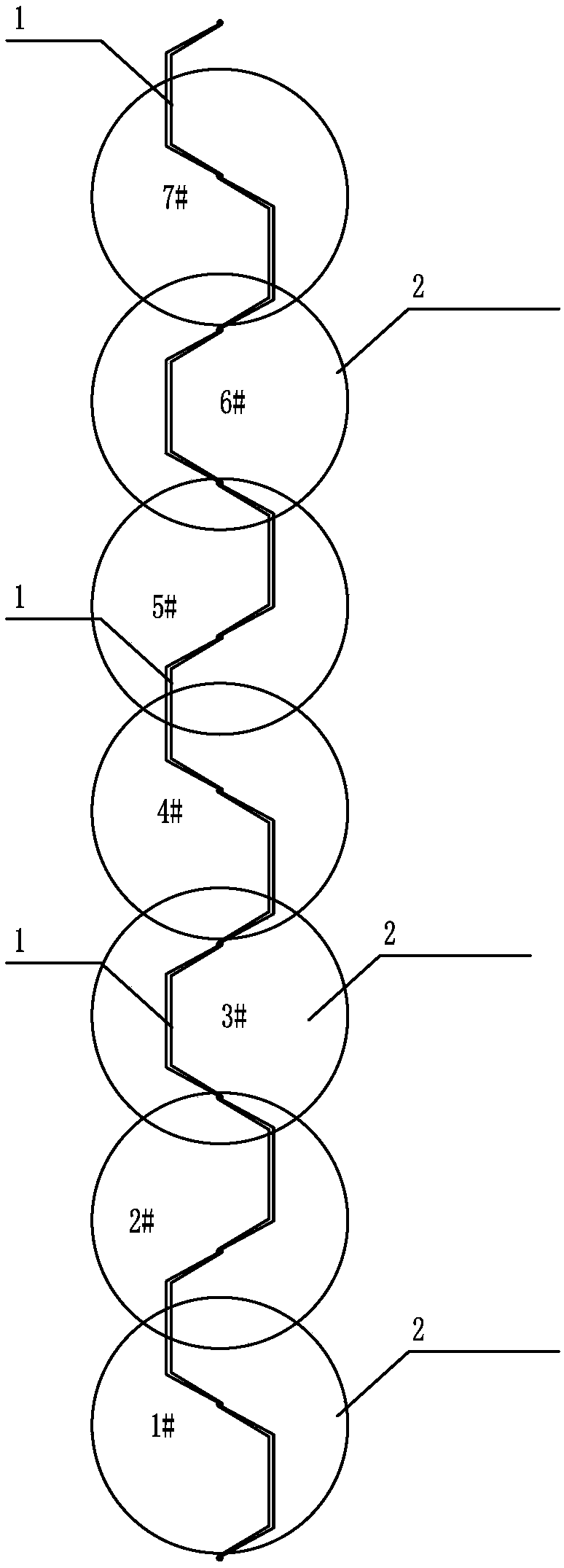

[0033] see Figure 1 to Figure 3 , the deep-water hard rock steel sheet pile cofferdam lead hole slotting and grouting construction method includes the following steps:

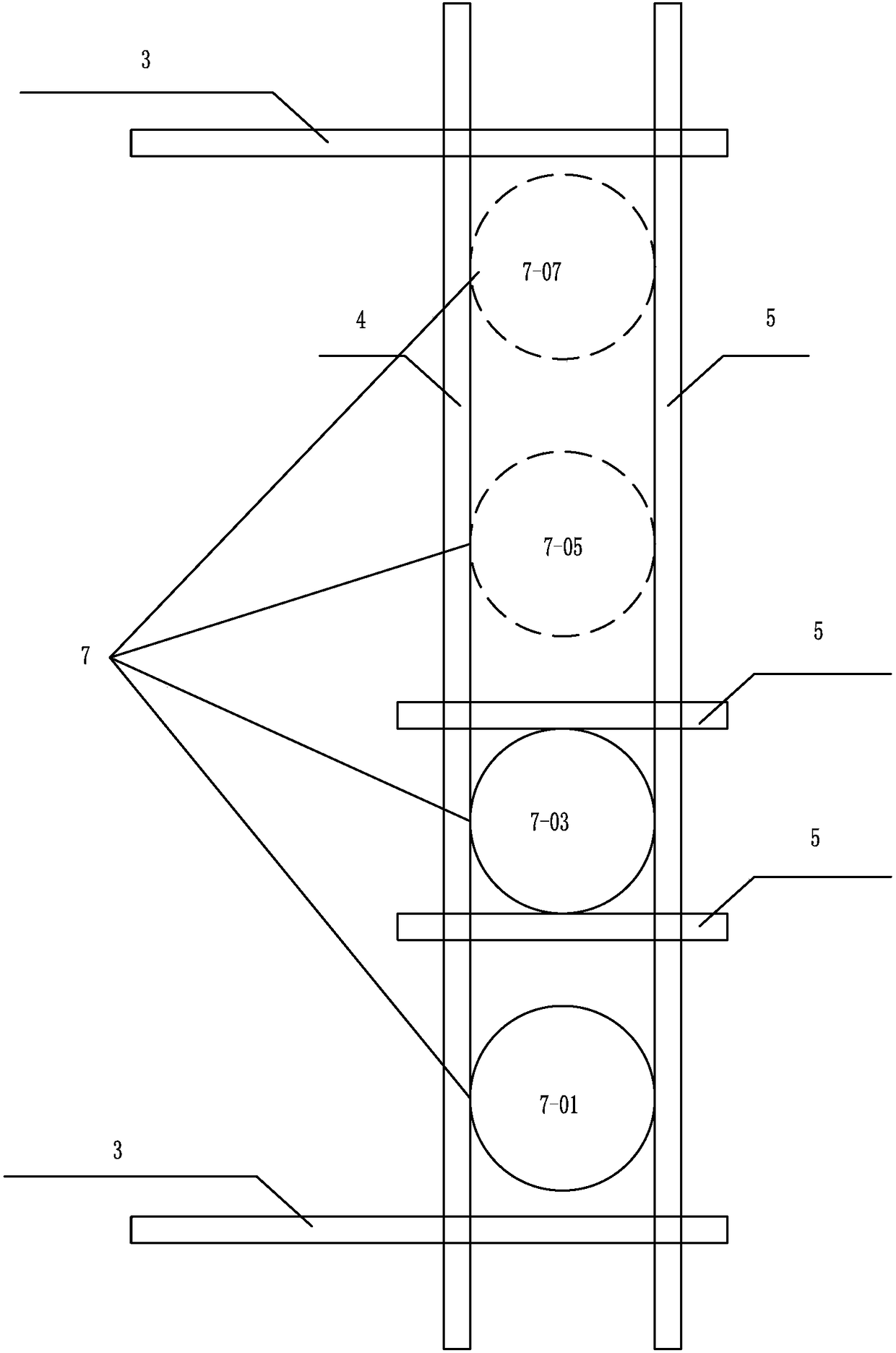

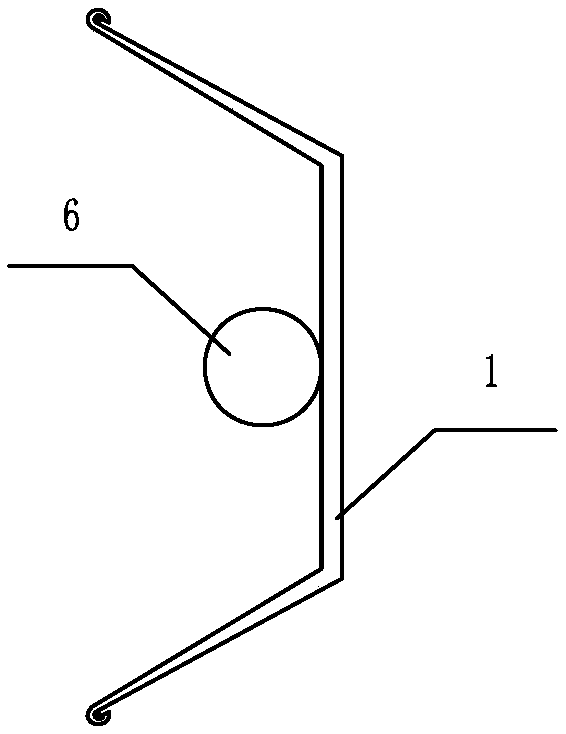

[0034] 1. Install guide hole casing guide frame; the deep-water hard rock steel sheet pile cofferdam lead hole slotting and grouting construction method described in the present invention needs to be used in conjunction with the lead hole casing guide frame, such as figure 2 Shown, guide hole casing 7 comprises 7-01, 7-03, 7-05, 7-07 four guide hole casings, and these four guide hole casings are arranged in a row, and guide hole casing guide frame comprises two A guide stringer 4, and two movable guide beams 5 arranged on the guide stringer 4. Corbels 3 are respectively provided near the two ends of the guide longitudinal beam 4, and the corbels 3 are used to connect the guide longitudinal beam and the movable guide beam 5 to the steel casing of the pile foundation. The structure is an upper and lower two-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com