Combined type heat preservation cavity module

A combination and cavity technology, which is applied in the direction of building components, buildings, building structures, etc., can solve the problems of inseparability, cracking and falling off of decorative layers, and raising costs, so as to enhance shear resistance and overall strength, enhance Anti-tension and anti-buoyancy, preventing grout leakage at seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

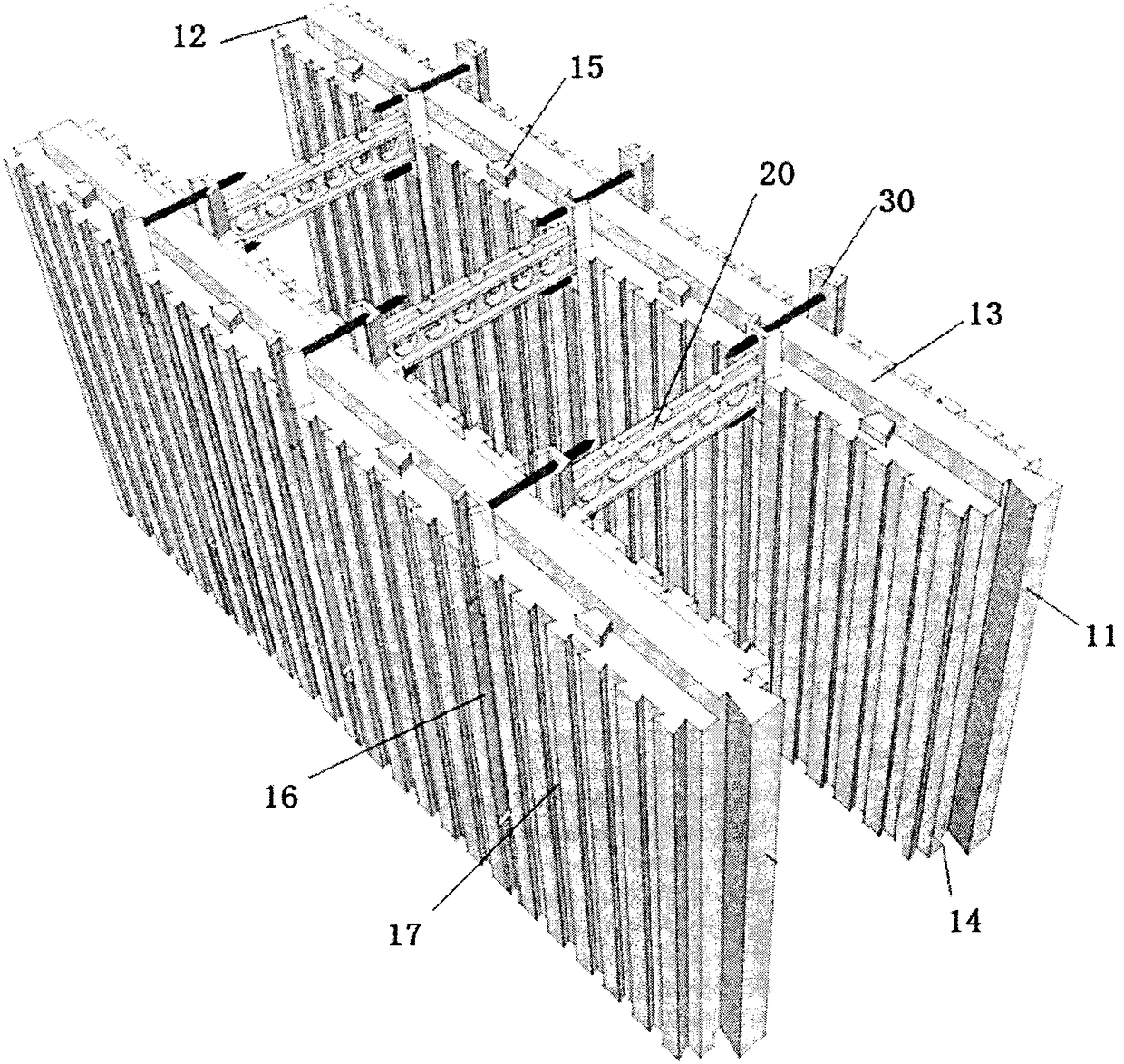

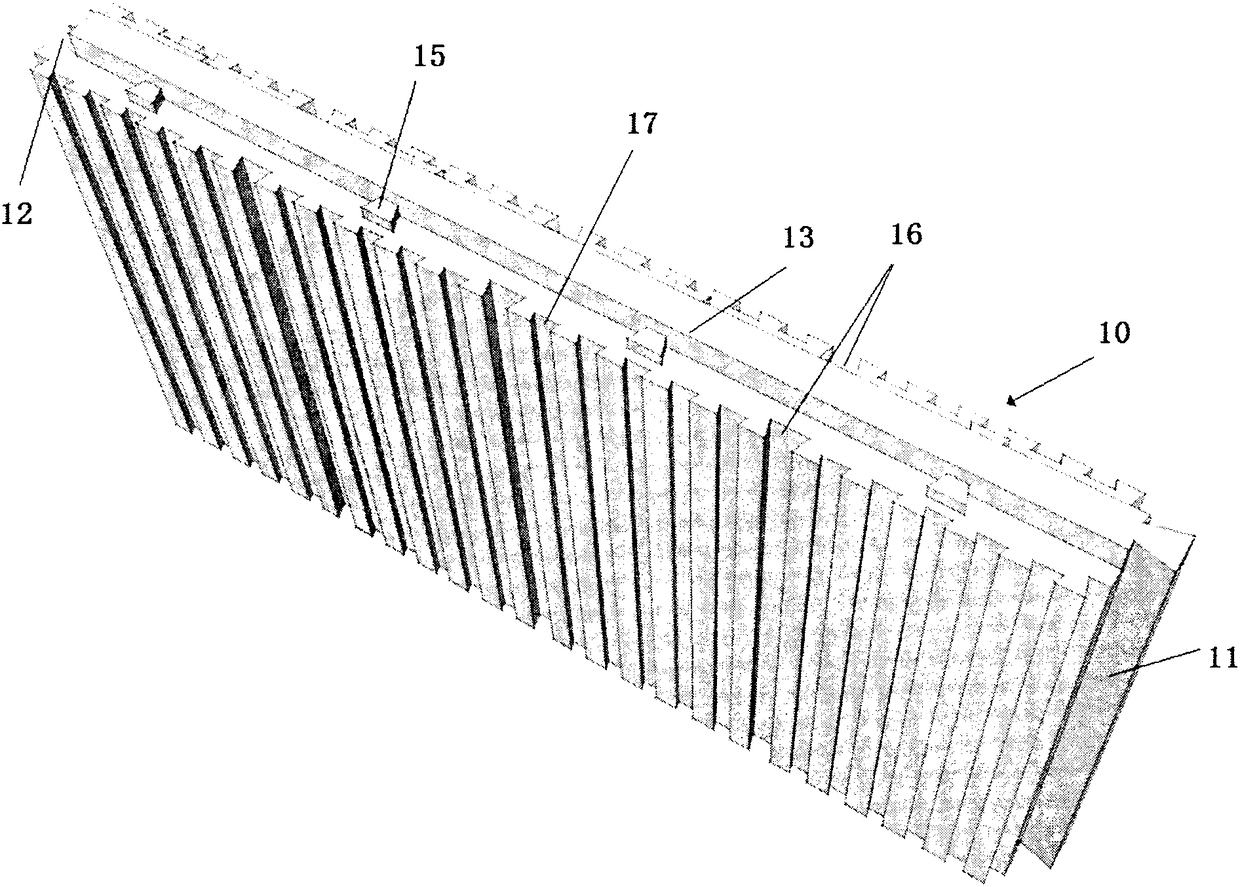

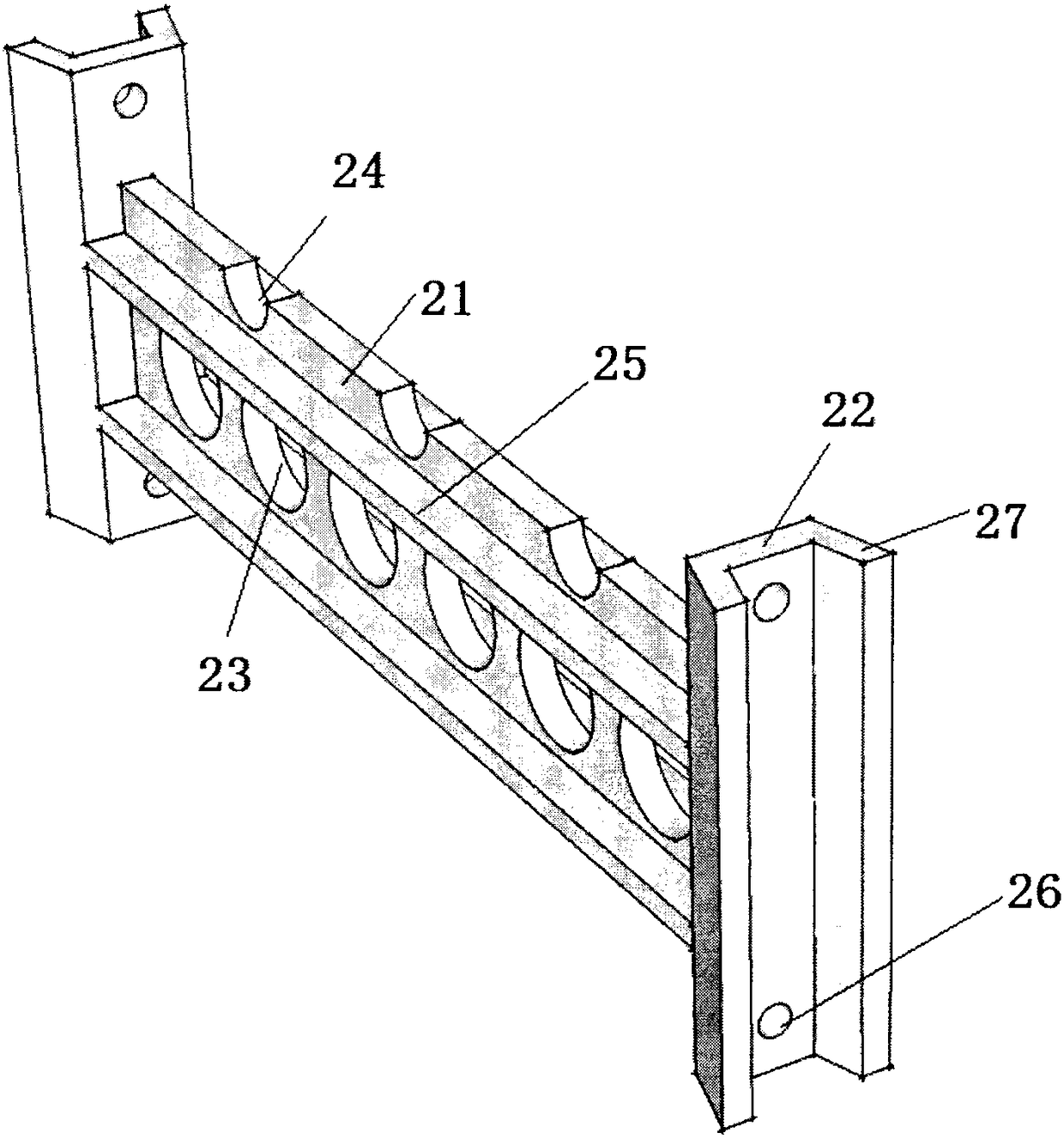

[0042] Such as figure 1 As shown, a combined thermal insulation cavity module includes an inner panel and an outer panel, and the inner panel and the outer panel are connected by a connecting piece 20. In this embodiment, both the inner panel and the outer panel are figure 2 The standard insulation module shown, the material of the standard insulation module can be EPS board, graphite polystyrene board, phenolic polystyrene board, extruded plastic insulation board, rock wool board, foamed cement board, perlite board or foam glass The board, in this embodiment, is preferably an EPS insulation board.

[0043] The standard heat preservation module includes a heat preservation module board body 10, which is placed vertically and has six sides, up, down, left, right, front and back, among which splicing mechanisms are set on the upper, lower, left and right sides, and the heat preservation module can be spliced and expanded through the splicing mechanism . In the present inven...

Embodiment 2

[0053] In this embodiment, through the connecting piece 20, the misaligned combination installation between the inner and outer panels of different heights can be realized, such as Figure 7 As shown, the heights between the inner and outer panels are different, one side adopts a standard thermal insulation module, and the other side adopts a dislocated thermal insulation module with a height smaller than or greater than the standard thermal insulation module, and the connecting piece 20 and the fixing piece 30 are all arranged on the bottom surface of the inner and outer panels, so that Just formed the thermal insulation cavity module of high and low combination. Such as Figure 7 As shown, the inner and outer panels of the thermal insulation cavity module with high and low combination are spliced and expanded in the vertical direction to form a wall combination. Increased shear resistance and overall strength of cavity modules. For example Figure 8 Among them, the spli...

Embodiment 3

[0055] In this embodiment, the combined installation between inner and outer panels of different thicknesses can be realized through the connecting piece 20, such as Figure 9 As shown, one side of the inner and outer panels adopts a standard thermal insulation module, and the other side adopts a thick thermal insulation module with a thicker thickness. For the upper and lower ends of the thermal insulation module, it is only necessary to lengthen the length of the bolts on one side of the thick thermal insulation module for connecting the fixing part 30 and the connecting part 20 . Through the combination of thermal insulation modules with different thicknesses, modular walls with different thermal insulation properties can be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com