A heating body and a vacuum sintering furnace realizing multi-zone temperature control

A technology of vacuum sintering furnace and heating body, which is applied to lighting and heating equipment, furnace, charge and other directions, can solve the problems of large temperature deviation, poor temperature control adjustability of equipment, large product size and performance deviation, etc. The effect of shrinking, full furnace yield improvement, and self-requirement reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

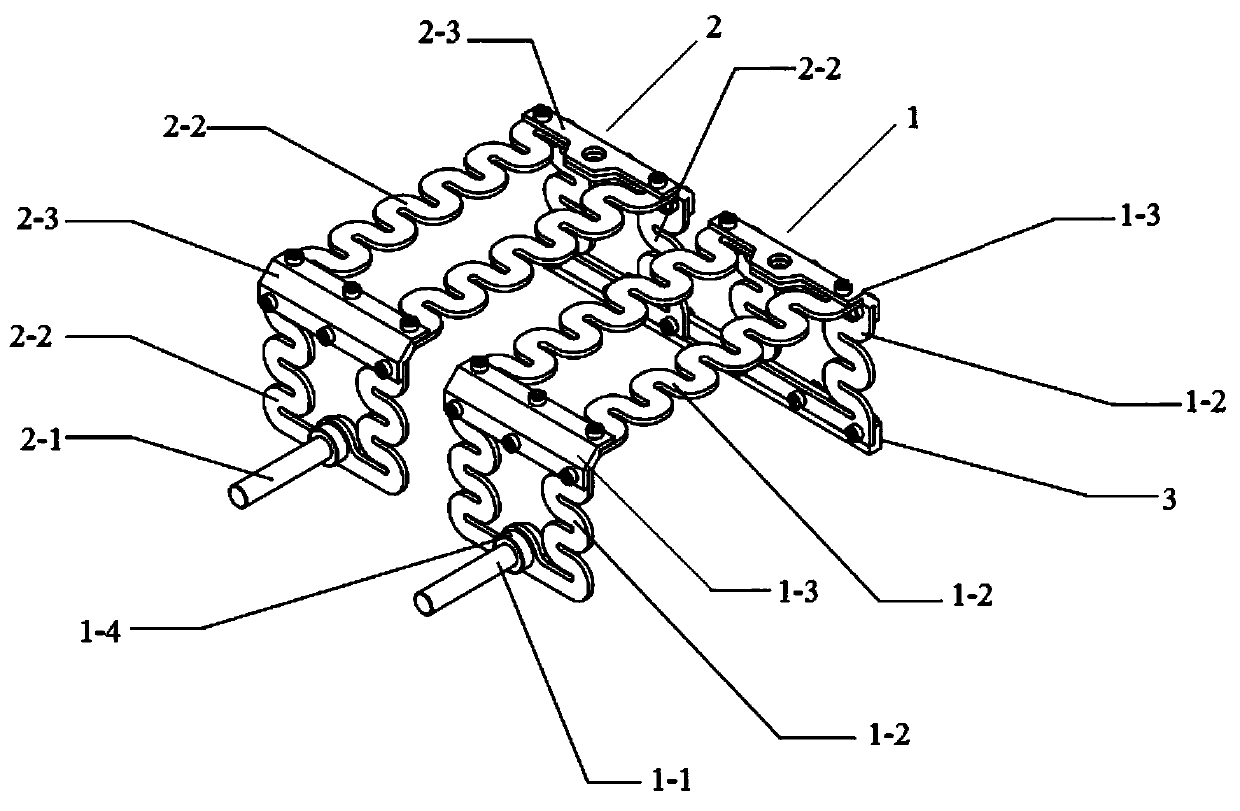

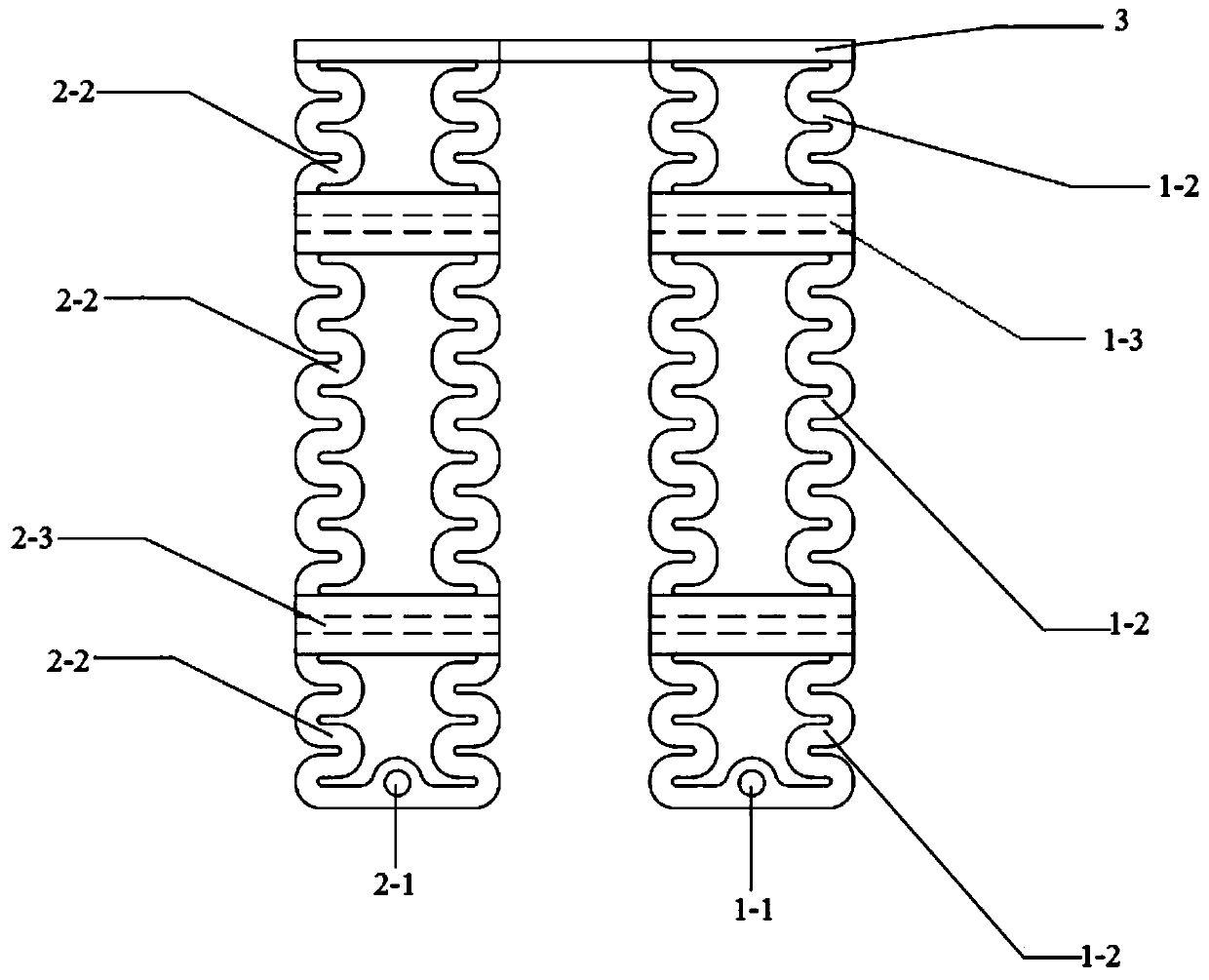

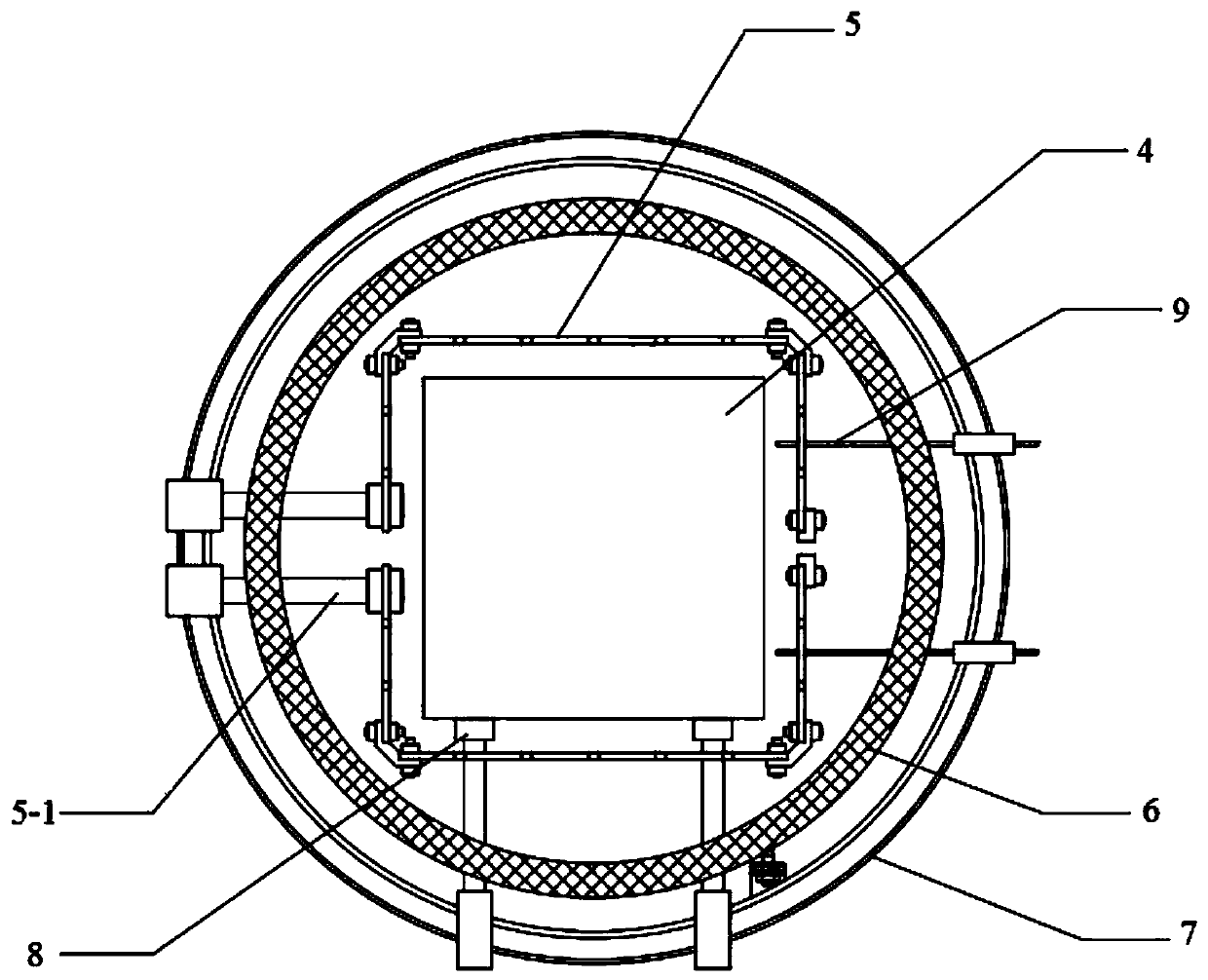

[0044] About a specific embodiment of the present invention is as follows:

[0045] The furnace body will be debugged and tested before shipment, and the temperature distribution is a necessary test.

[0046] For example, when the set temperature in the furnace is 800°C, the sensor detects the temperature at 6 different positions in the furnace, such as Figure 6 as shown, Figure 6 It is the distribution schematic diagram of the temperature detection point in the furnace of the specific embodiment of the present invention, and black dot represents detection point, and the temperature that each detection point records is as follows:

[0047] Point 1 is 800°C, point 2 is 810°C, point 3 is 795°C, point 4 is 800°C, point 5 is 805°C, and point 6 is 790°C.

[0048] At this time, point 1 is 800°C, and point 6 is 790°C.

[0049] At this time, if the upper and lower 2-zone temperature control design is adopted, that is, two heating bodies are used for heating. Since point 1 and poi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com