Real-time monitoring method of track error of five-axis linkage processing machine tool

A five-axis linkage and processing machine tool technology, which is applied in computer control, instruments, simulators, etc., can solve the problems that affect the processing efficiency and quality, and the machine tool trajectory error monitoring cannot realize real-time monitoring, etc., to achieve strong openness and simple calculation process Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

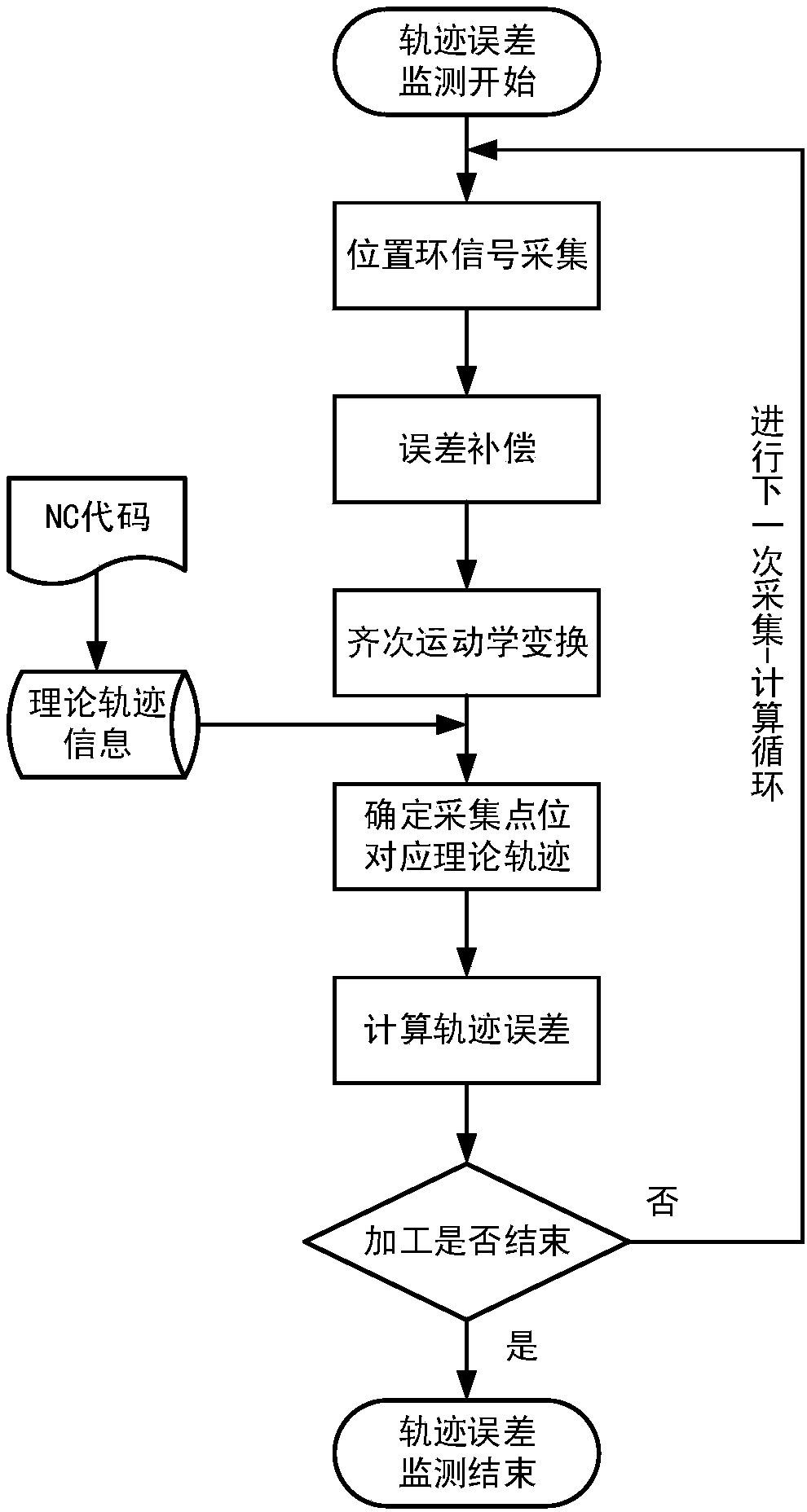

[0040] Such as figure 1 shown.

[0041] A method for real-time monitoring of trajectory error of a five-axis linkage processing machine tool. Its biggest feature is that the trajectory error monitoring is an acquisition-calculation cycle process that has nothing to do with the interpolation period. The specific steps are:

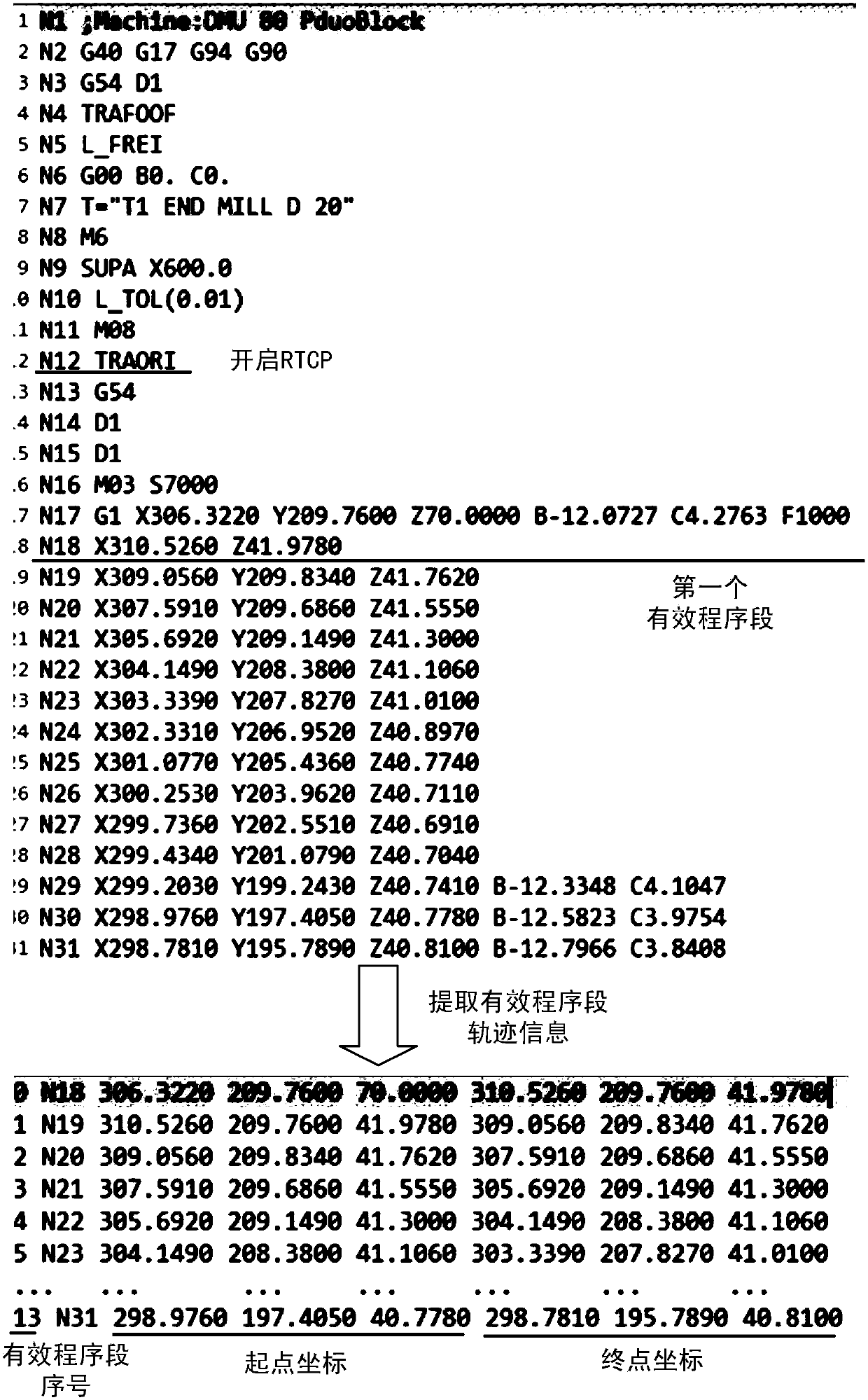

[0042] First, read the NC code before processing, extract and sequentially store the theoretical trajectory information corresponding to the program segment;

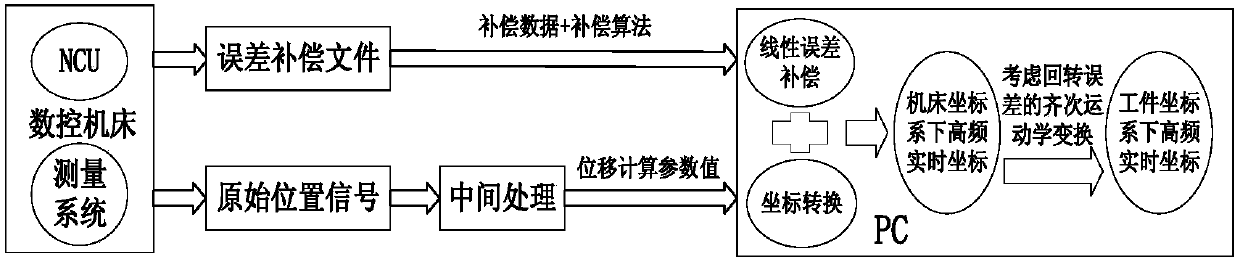

[0043] Secondly, during the machining process, based on the acquisition and analysis of the position loop signal of the machine tool servo system, error compensation and homogeneous kinematic transformation, the actual tool position coordinates in the workpiece coordinate system are obtained;

[0044] Third, use the time sequence and the method of analyzing the rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com